Chute with buffer function for loading and unloading bulk materials

A bulk material and chute technology, which is applied in the field of bulk material loading and unloading chute, bulk material loading and unloading transportation, can solve the problems of material quality impact, environmental pollution, etc., achieve low cost, simple overall structure, and reduce impact force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

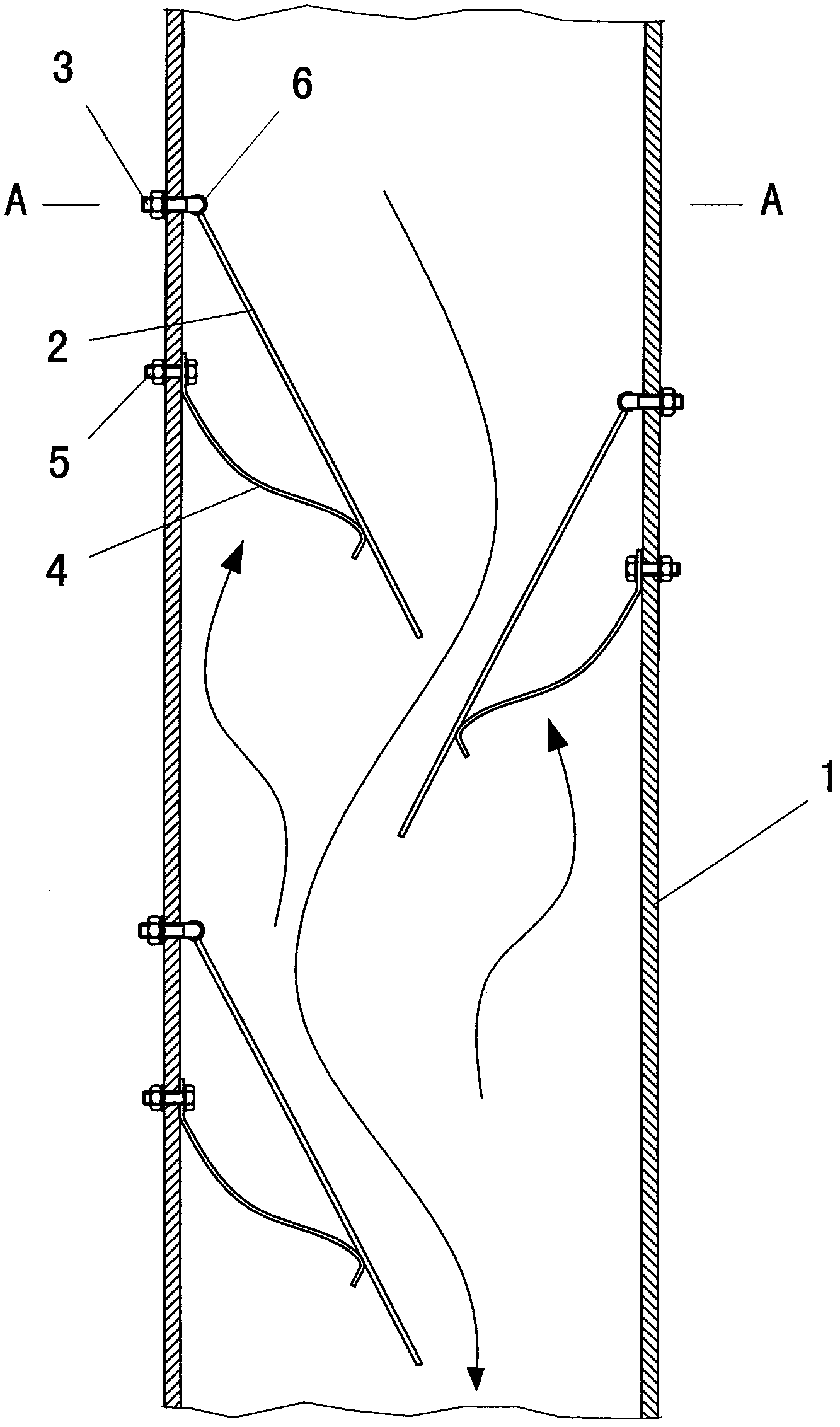

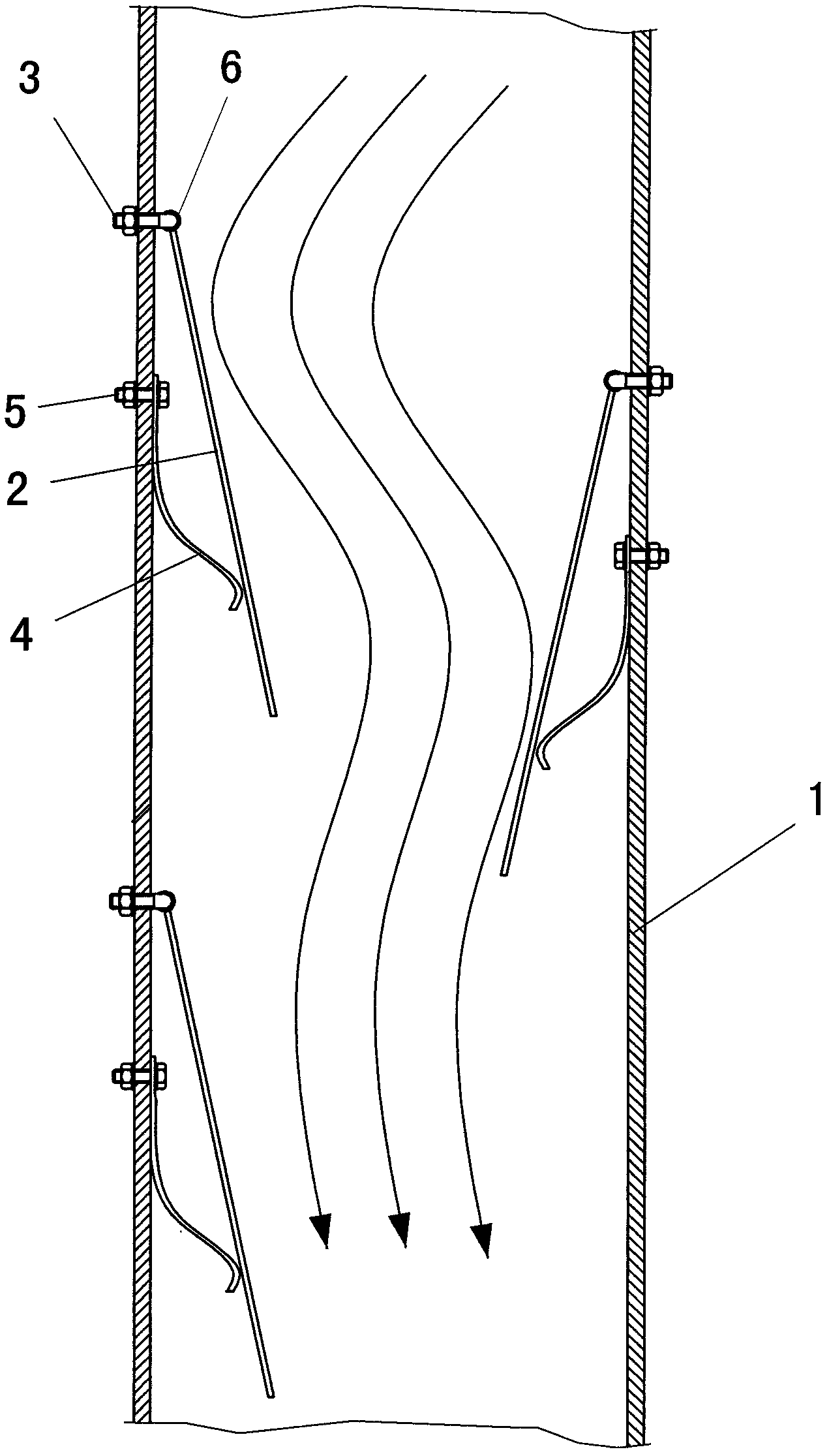

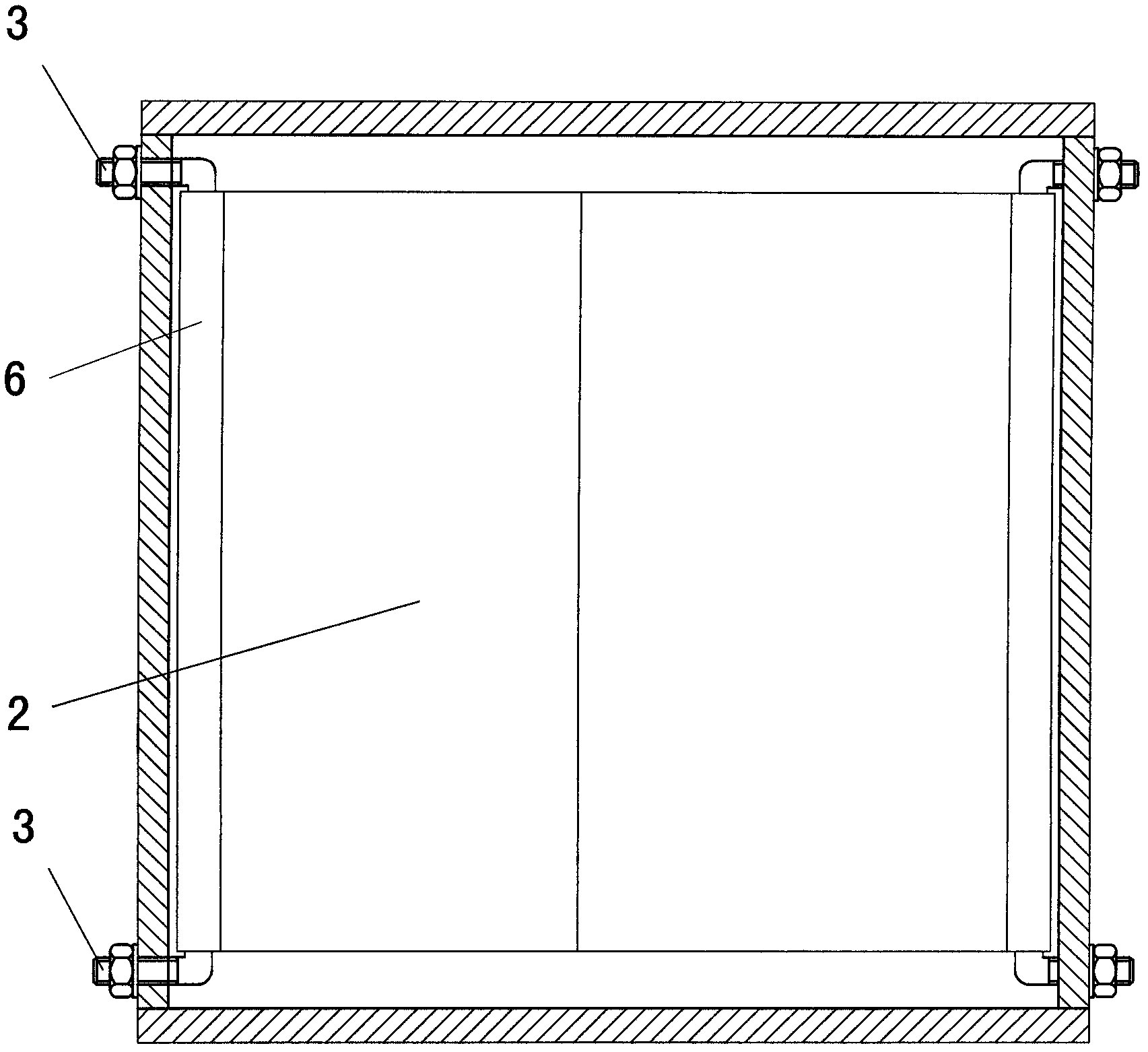

[0011] Such as figure 1 , 2 , Shown in 3: 1 is the cylinder body of chute cylinder, is welded with connecting flange at cylinder body 1 two ends, is convenient to join with other parts. The cylinder body 1 is fabricated by welding metal plates, and its section can be square or circular or in other shapes. In this embodiment, a cylinder structure with a square cross section is selected.

[0012] A buffer plate 2 is installed inside the cylinder body 1, and the buffer plate 2 is connected to the cylinder body 1 in a rotational manner, that is, the buffer plate 2 can rotate at a certain angle in the cylinder body 1 relative to the side wall of the cylinder body 1. The specific connection method is: the side of the buffer plate 2 has curling 6; One end is fixedly connected with the side wall of the barrel 1 through a nut. 4 is an elastic piece, and the elastic piece 4 is in the form of a spring piece. One end of the spring piece is fixedly connected with the side wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com