Construction method of tank wall of oil tank

A construction method and oil storage tank technology, which are applied in the field of crude oil storage tanks, can solve the problems of difficulty in ensuring construction quality and speed, insecure construction safety, inconvenience in construction, etc., so as to shorten the construction period, reduce construction procedures and construction procedures. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

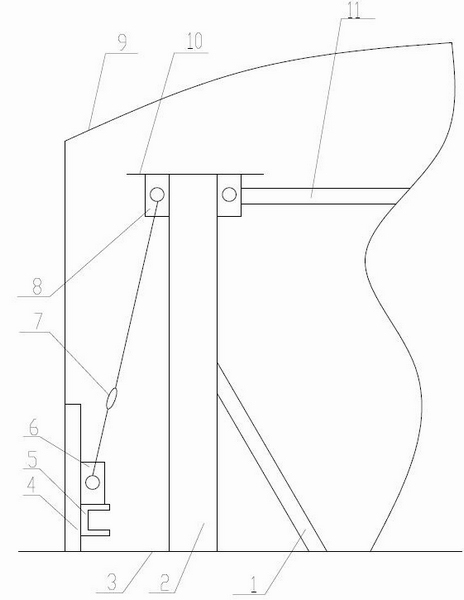

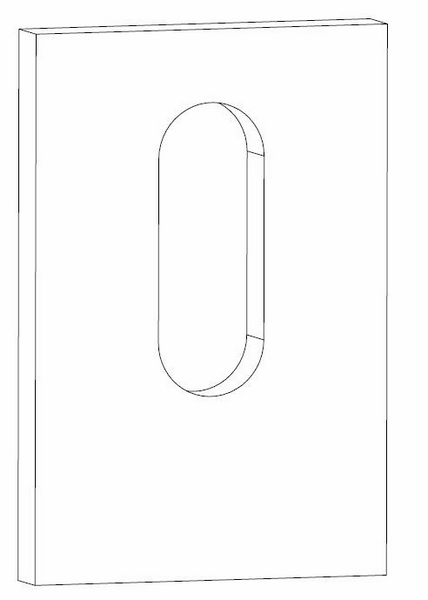

[0021] See attached figure 1 , attached figure 2 And attached image 3 , a construction method for the wall panels of an oil storage tank, which adopts the inversion method, that is, firstly install the topmost wall panels, and finally install the bottommost wall panels, and lift by means of an inverted chain lifting device, the steps of the method include:

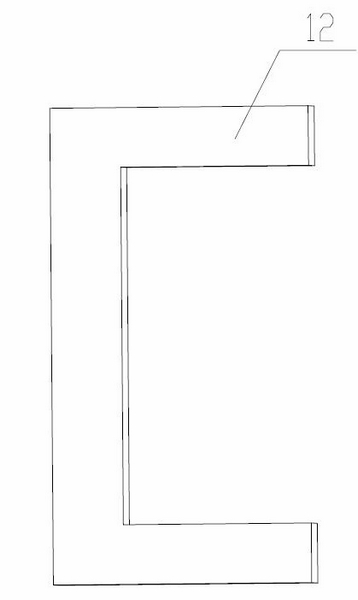

[0022] 1) After the inspection of the tank bottom is qualified, draw a large circle on the tank bottom plate 3 according to the design diameter of the wall plate, and assemble and weld a section of 300mm long No. To control the diameter of the tank body of the oil storage tank, a 80×60×10mm baffle is welded on the channel steel to reinforce the channel steel.

[0023] 2) Assemble the first wall panel (counting from top to bottom, i.e. the top wall panel): first hoist the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com