Engine exhaust system and method

An exhaust system and engine technology, applied in engine components, combustion engines, engine control, etc., can solve problems such as affecting the efficiency of the exhaust treatment system and reducing the quality of exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

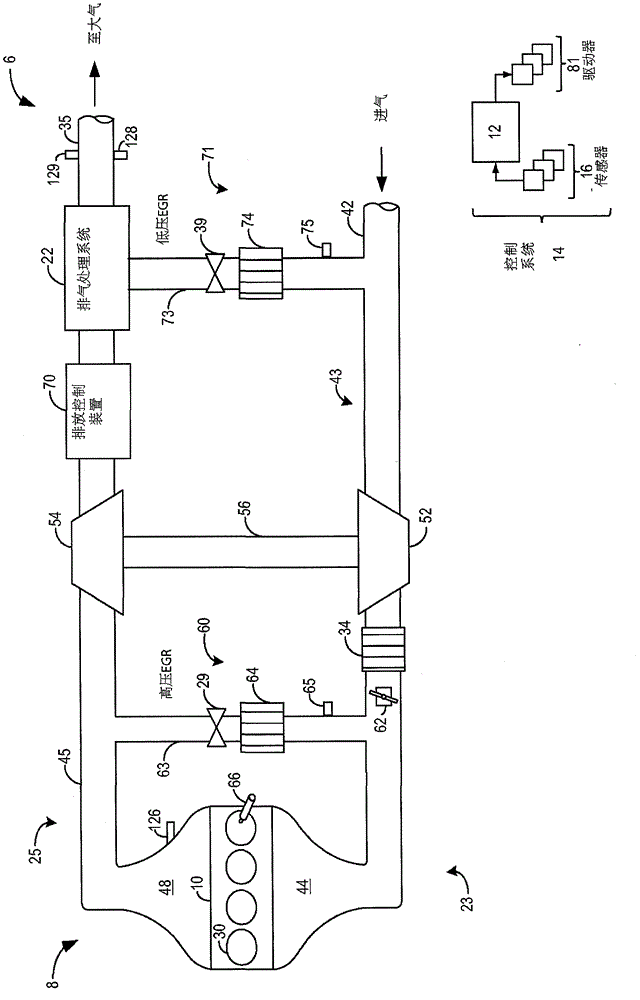

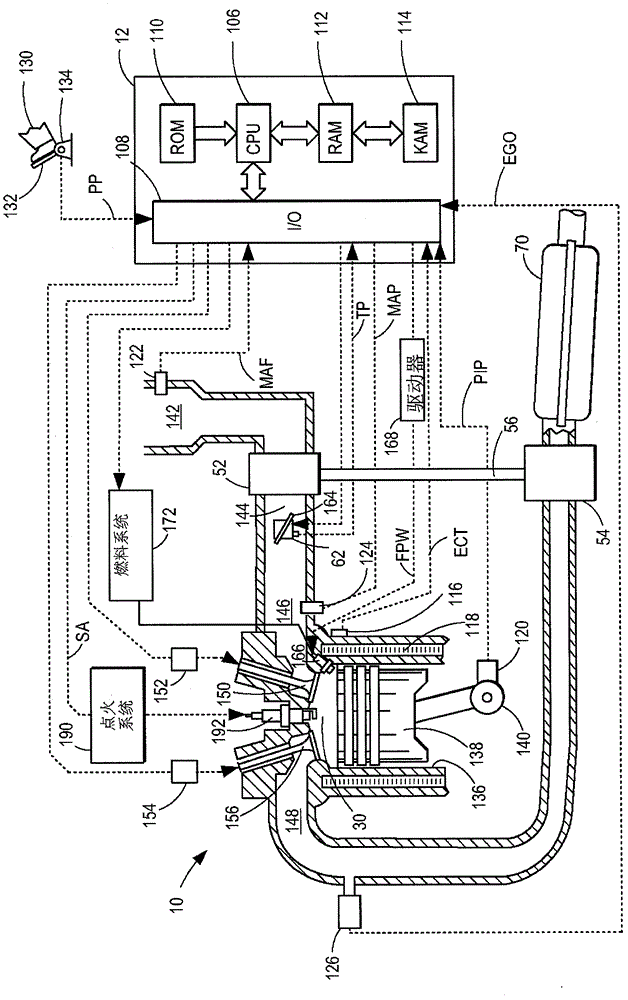

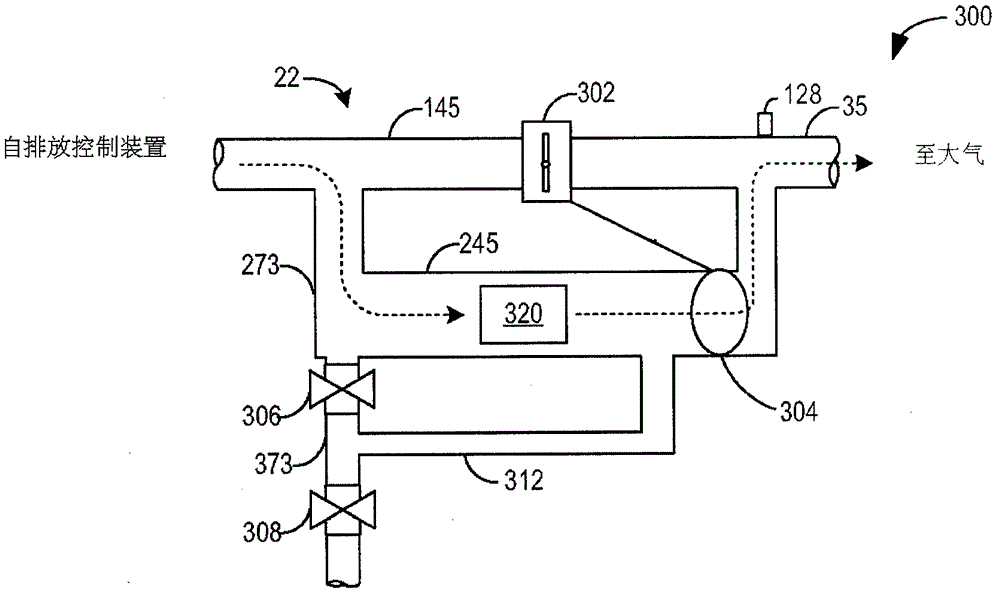

[0027] The following description relates to systems and methods for operating an exhaust treatment system associated with an internal combustion engine to remove hydrocarbons from exhaust emissions. For example, exhaust gas treatment systems are available for diesel engines equipped with exhaust gas temperature coolers. like figure 1 As shown, by coupling the operation of the engine's exhaust treatment system with the low pressure EGR system, advantageous synergy may be obtained. like Figure 3-5 As shown in , by coordinating the opening of the exhaust gas treatment system valve with the EGR valve of the EGR system, cold start exhaust HC can be effectively captured for subsequent reaction or can be recycled into the engine intake system. The exhaust treatment system may include an integrated exhaust valve system including an exhaust valve connected to the isolation valve ( Figures 6A-6K ). Exhaust valve systems can be arranged so that the opening of one valve is linked to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com