Progressive small and medium sized in-storehouse ventilation system with pumping, air exchanging, dehumidifying and cooling functions

A ventilation system, small and medium-sized technology, applied in the field of ventilation systems, can solve problems such as difficult single-pipe ventilation, large-scale valley coolers, poor airflow in high-impurity areas, and inconspicuous cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

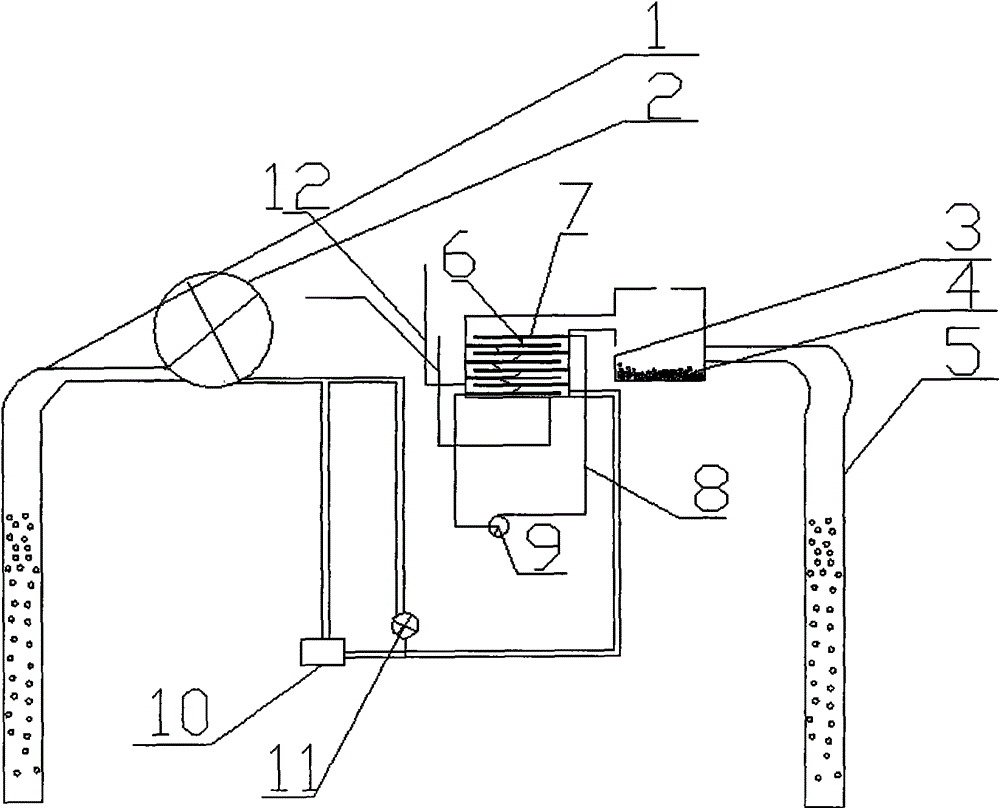

[0015] The perforations of two ventilation single pipes are more on one side and less on one side; lime, silica gel and other absorbent materials are placed on the bottom plate of the ventilation chamber 3.

[0016] Hierarchical suction, ventilation, dehumidification, and cooling ventilation system for small and medium-sized warehouses, characterized in that: the inlet of the fan 2 is connected to the single ventilation pipe 1 at the inlet end, and the outlet of the fan 2 passes through the compressor-type dewatering and cooling device 10 and the strake heat transfer condensation chamber The strake heat transfer condensing chamber is connected to the ventilation chamber 3, and the ventilation chamber 3 is connected to the ventilating single pipe 5 at the outlet end; The three-way valve is directly connected to the fan 2; the strake heat transfer condensing chamber has built-in multiple reclaimed water plates 7, and the multiple reclaimed water plates 7 are connected by water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com