Light emitting diode (LED) packaging process

A technology of LED packaging and LED brackets, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low color rendering index, poor color rendering, and the color of white light tubes is not soft enough, so as to improve the color rendering and area. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

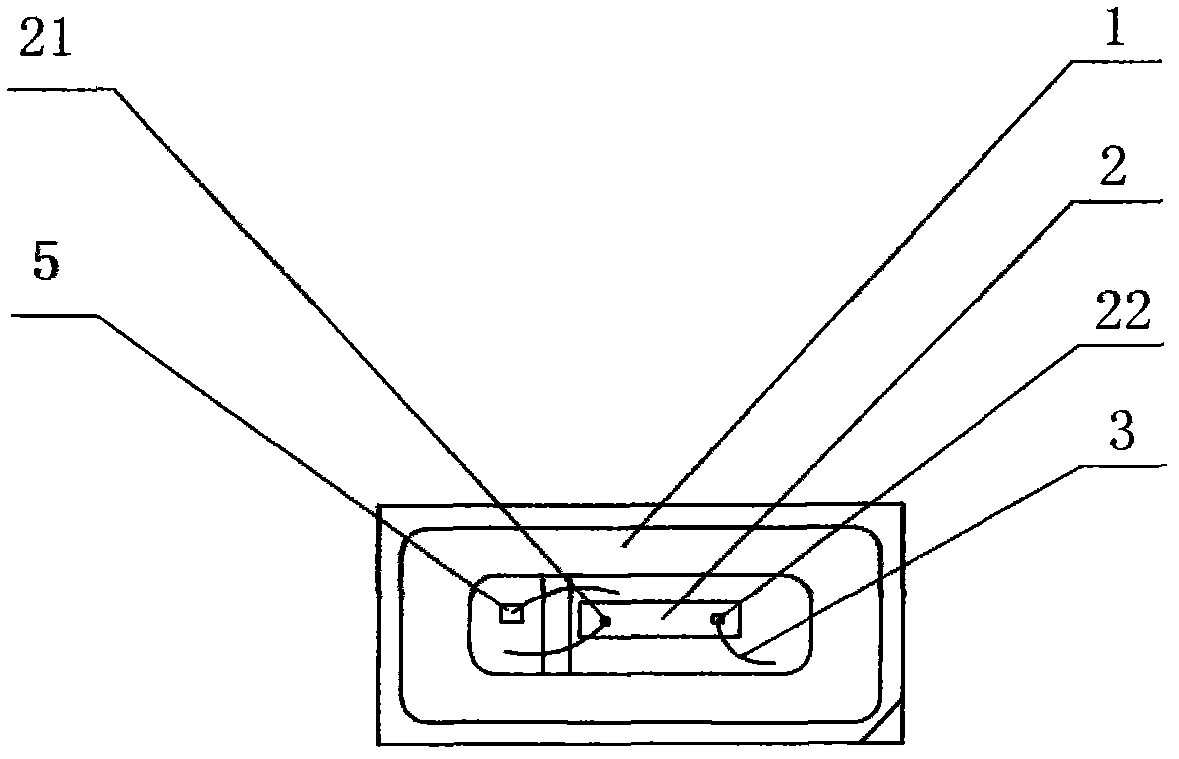

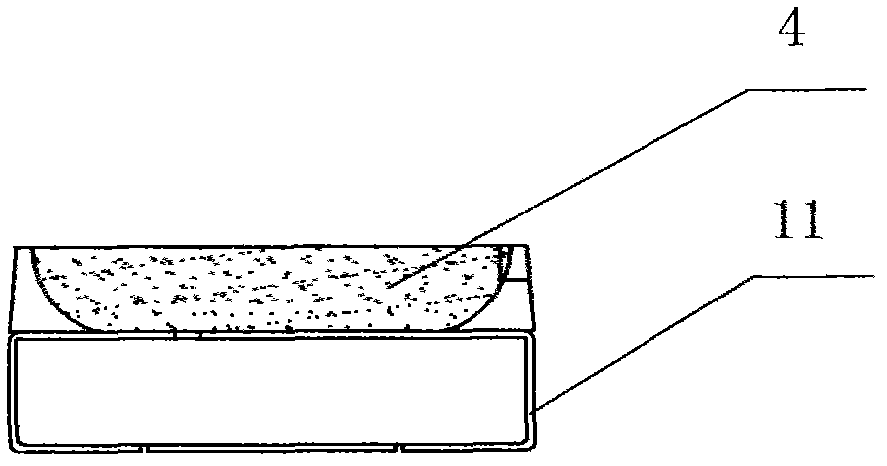

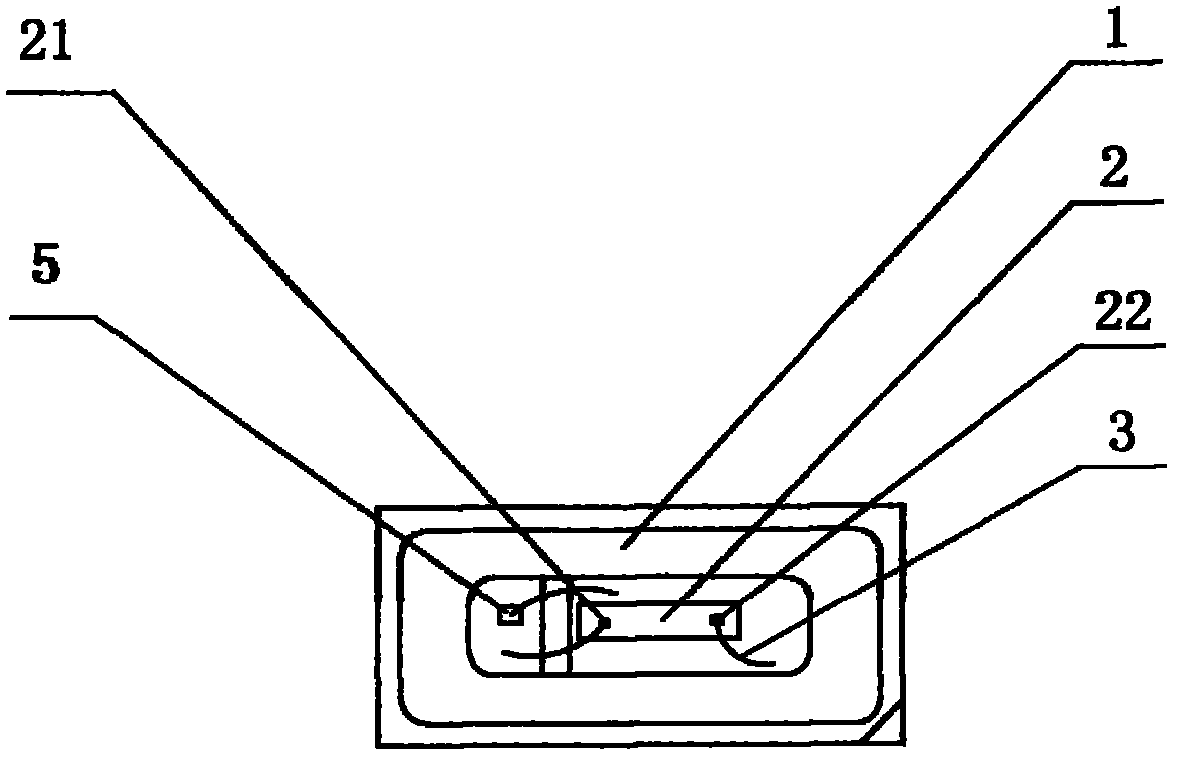

[0019] Such as figure 1 , figure 2 Commonly shown, an LED packaging process includes the following steps: (1) provide an LED bracket 1, and the material of the LED bracket 1 is white PPA plastic. Since the thermal deformation temperature of PPA plastic is as high as 300°C and the continuous use temperature can reach 170°C, it can maintain its superior mechanical properties such as strength, hardness, fatigue resistance and anti-fatigue in a wide temperature range and high humidity environment Creep resistance, which can meet the short-term and long-term heat resistance required by LED brackets. In this embodiment, the material of the LED bracket electrode 11 and the bottom of the cooling cup is C194 lead frame copper strip, which belongs to Cu-Fe-P copper alloy, has high strength, high electrical conductivity, high thermal conductivity, and good Excellent properties such as weldability, wettability, plastic sealing, and oxidation resistance.

Embodiment 2

[0026] Embodiment 2 is basically the same as Embodiment 1, except that the fluorescent glue is prepared from the following raw materials in parts by weight: nitride red phosphor TMR-500630-254530, 7; high-power phosphor HY-Y805, 93; green phosphor TMG-300520, 5; transparent silicone 8670, 1000.

Embodiment 3

[0028] Embodiment 3 is basically the same as Embodiment 1, except that the fluorescent glue is prepared from the following raw materials in parts by weight: nitride red phosphor TMR-500630-254530, 10; high-power phosphor HY-Y805, 95; green phosphor TMG-300520, 2; transparent silicone 8670, 1000.

[0029] Since the fluorescent glue of the present invention is based on the high-power fluorescent powder HY-Y805, the high-color-rendering nitride red phosphor TMR-500630-254530 and the green fluorescent powder TMG-300520 are added, and the prepared fluorescent glue can be Make up for the defects of various colors of light, make the final white light closer to sunlight, improve the color rendering, and the color rendering index can be increased to 95, making the white light more comfortable and soft. The white light LED obtained after packaging has a small area of only 4.2 square millimeters. It satisfies people's requirements for short, light and thin white light sources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com