Hydraulic drive device for construction machine

A driving device, engineering machinery technology, applied in the direction of fluid pressure actuating device, mechanical equipment, fluid pressure actuating system components, etc., can solve problems such as control instability, achieve good startability, reduce the load of hydraulic pumps, avoid The effect of response delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

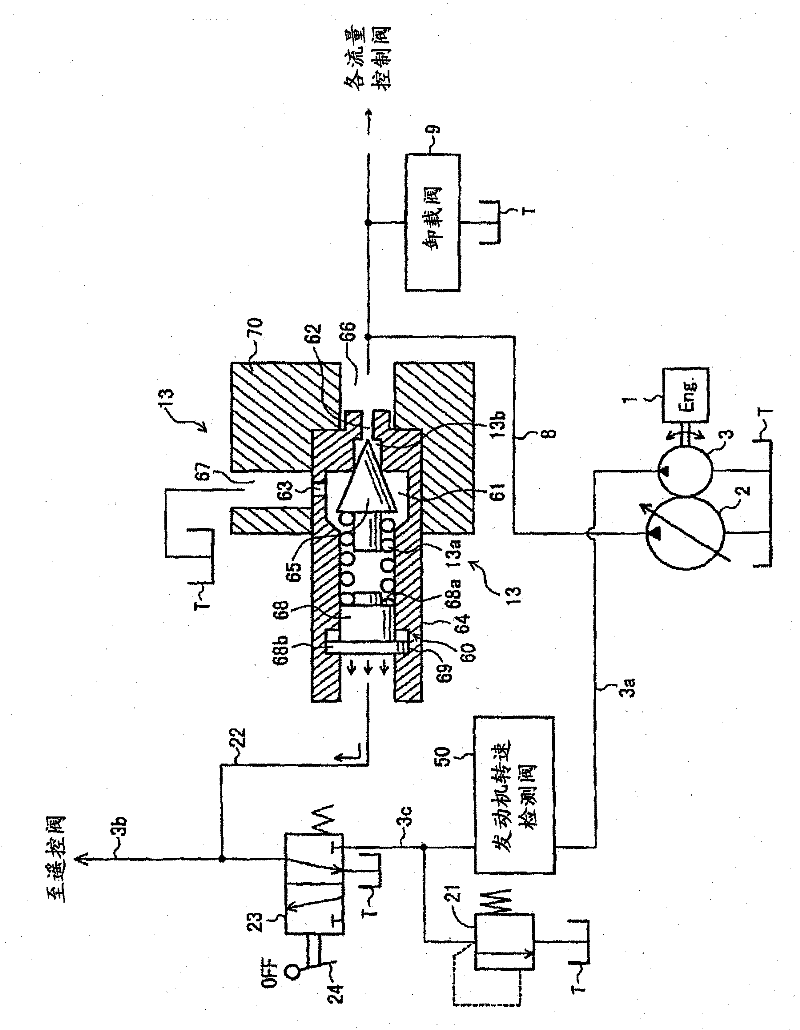

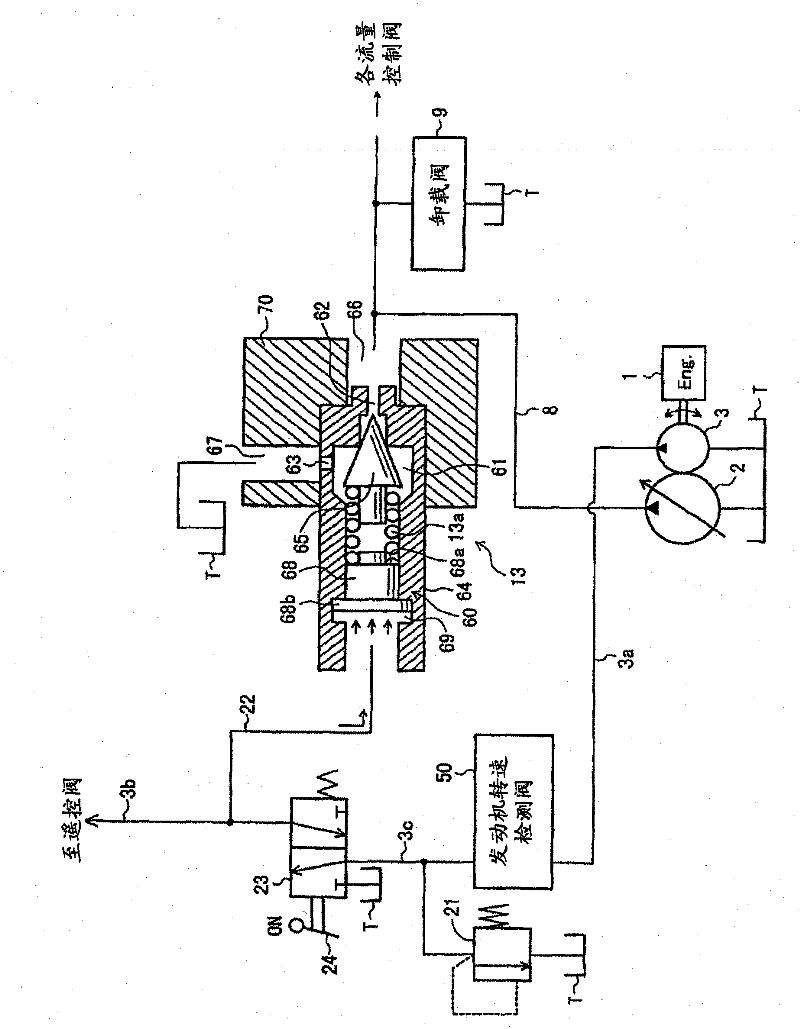

[0034] Embodiments of the present invention will be described below using the drawings.

[0035] ~Structure~

[0036]

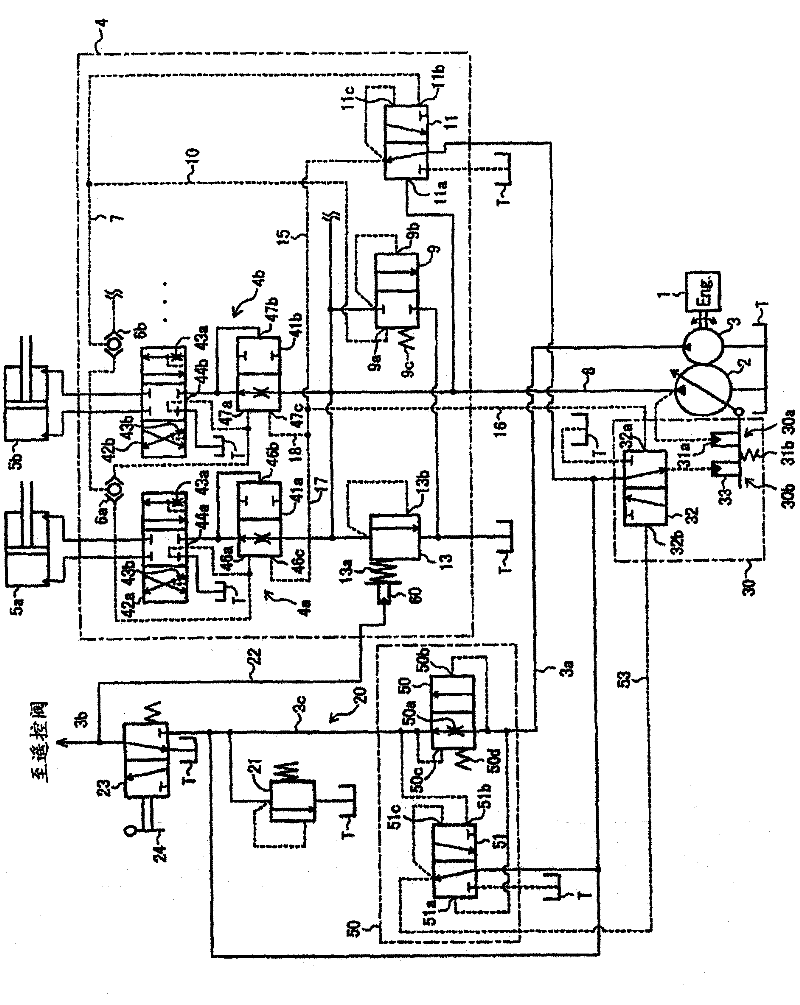

[0037] figure 1 It is a hydraulic circuit diagram showing the hydraulic drive device of one embodiment of the present invention.

[0038] exist figure 1 Among them, the hydraulic drive device of the present embodiment includes: an engine 1; a variable displacement hydraulic pump 2 and a fixed displacement pilot pump 3 as a master pump driven by the engine 1; a control valve 4; a slave hydraulic pump 2. The discharged pressurized oil is guided through the control valve 4, and passes through a plurality of actuators 5a, 5b, . . . driven by the pressurized oil.

[0039] The control valve 4 has: a plurality of valve members 4a, 4b, . A plurality of pressure compensating valves 41a, 41b, ... and a plurality of flow control valves (main spool valves) 42a, 42b, ... for separately controlling the flow (flow rate and direction) of pressure oil; Shuttle spool val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com