Image forming device

A technology of image and nozzle, applied in the direction of power transmission device, printing, transfer materials, etc., can solve the problems of recording head position deviation, position deviation, intense vibration of printing car, etc., and achieve the effect of inhibiting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0158] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the structural part which has the same function or the procedure which performs the same process, and the overlapping description is abbreviate|omitted.

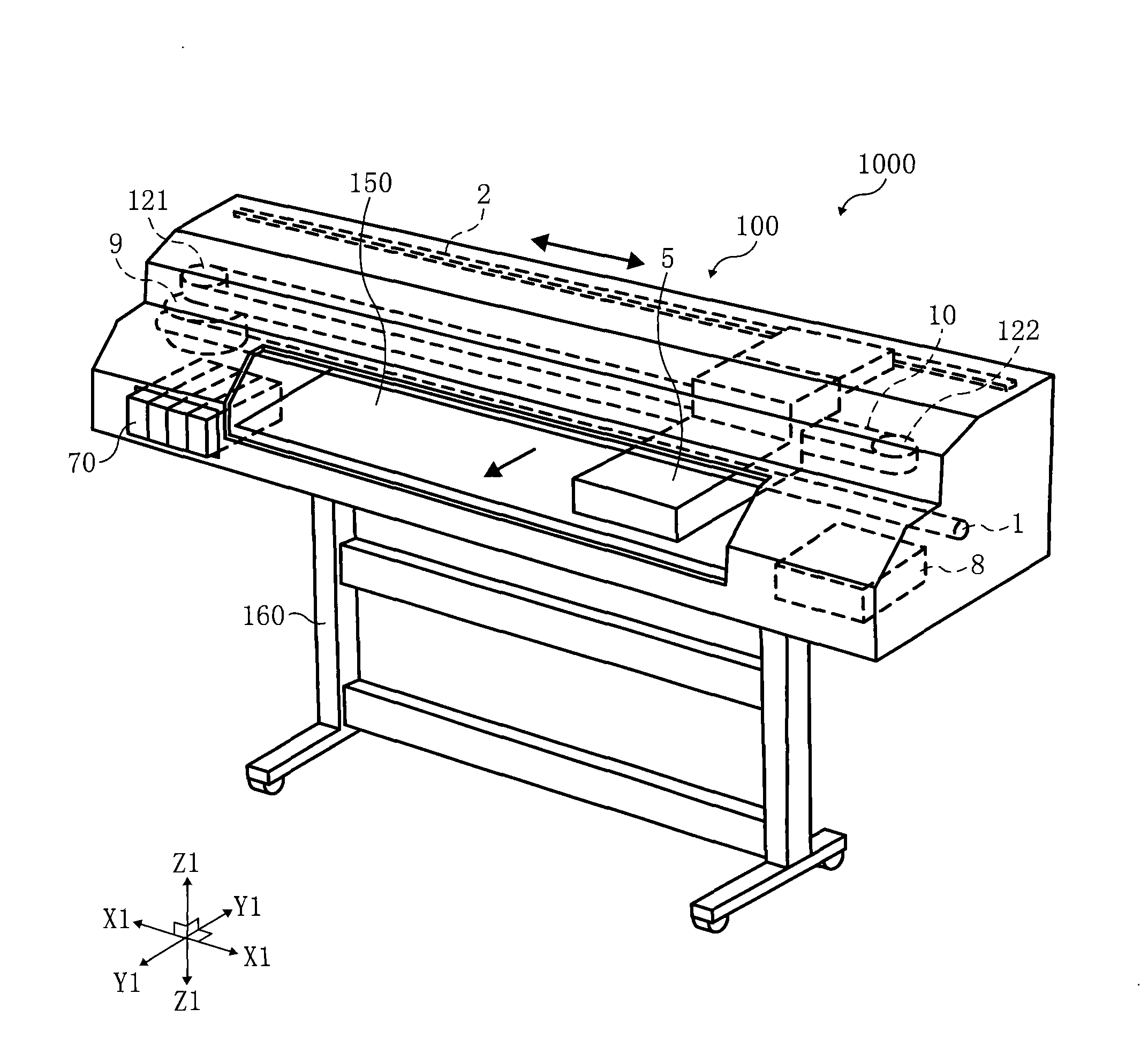

[0159] The image forming apparatus 1000 of this embodiment can be roughly divided into a recording apparatus 100 and a paper feeding unit. The recording device 100 is mainly composed of a mechanism that injects ink into a recording medium (for example, paper) through a recording head by an inkjet method to form an image, and the paper feeding unit is mainly composed of a mechanism that transports the recording medium into the recording device.

[0160] [Summary of the overall configuration of the recording device]

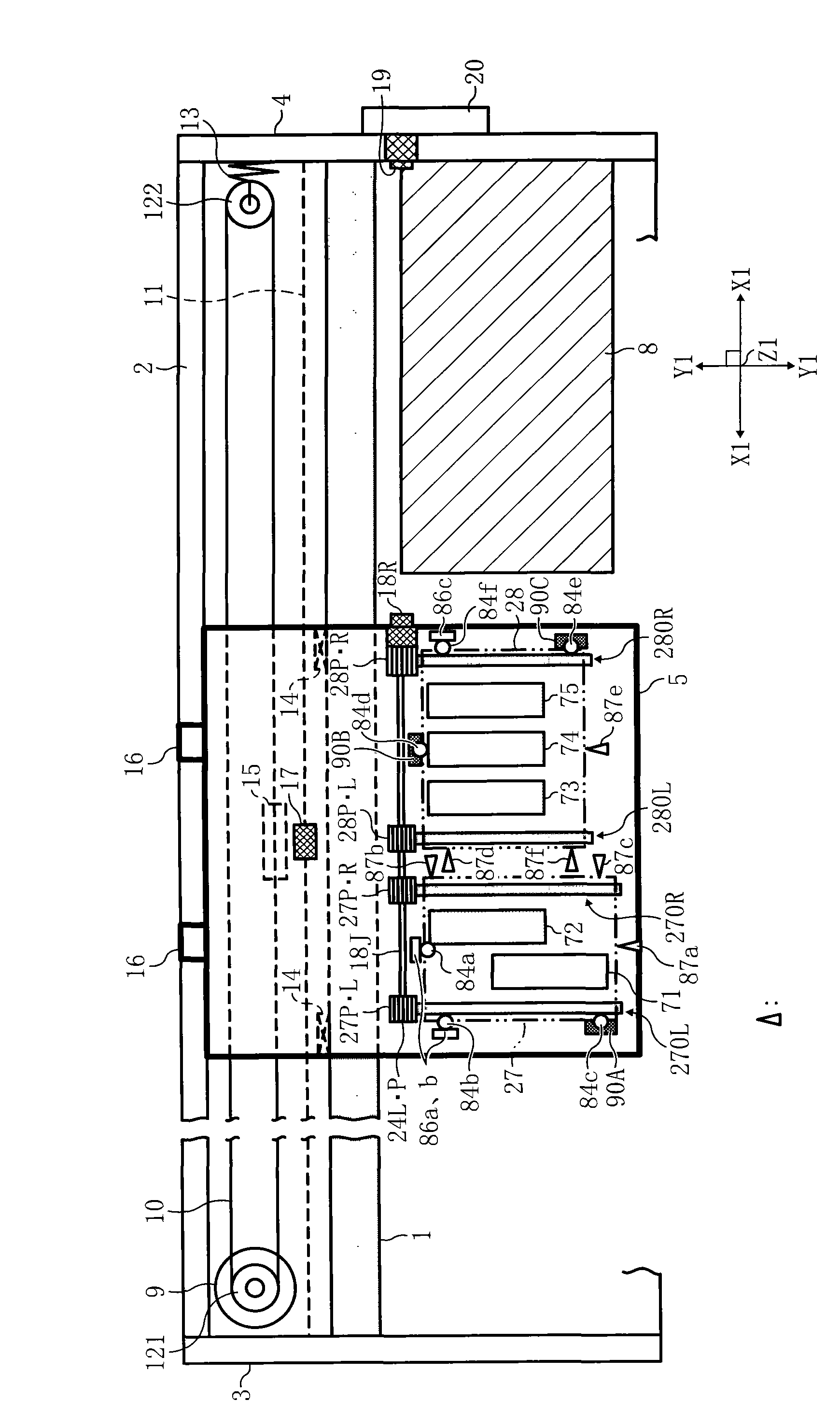

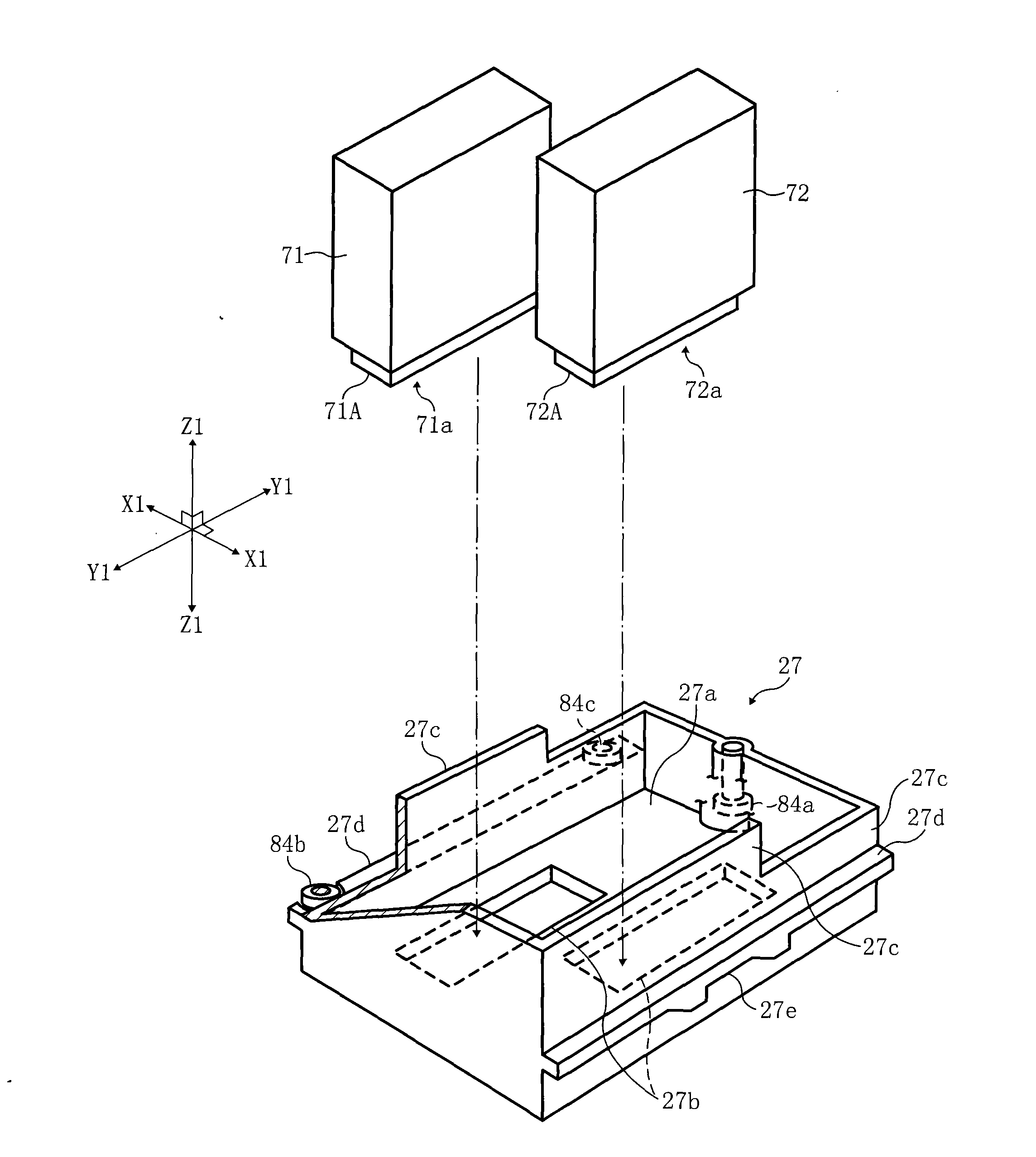

[0161] A perspective view of the image forming apparatus 1000 and the recording apparatus 100 is shown in figure 1 As shown, a schematic diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com