Spherical basic ammonium ferric phosphate powder with large specific surface area and preparation method thereof

A high specific surface area, ammonium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low tap density of lithium iron phosphate products, affecting the electrochemical performance of batteries, and lengthening ion diffusion paths. , to achieve the effect of short ion diffusion path, avoid wide particle distribution and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Solution preparation: Prepare 1mol / L ferric citrate aqueous solution and ammonium dihydrogen phosphate aqueous solution respectively.

[0023] With above-mentioned two kinds of solutions according to molar ratio Fe:P=1:1.5, join in the reaction container under stirring respectively at the same time, reaction temperature is controlled at 50-60 ℃, after dropping, adjust with ammonia water (concentration is 20%) The pH value is adjusted until the pH value is 4 to obtain an amorphous basic ammonium ferric phosphate slurry.

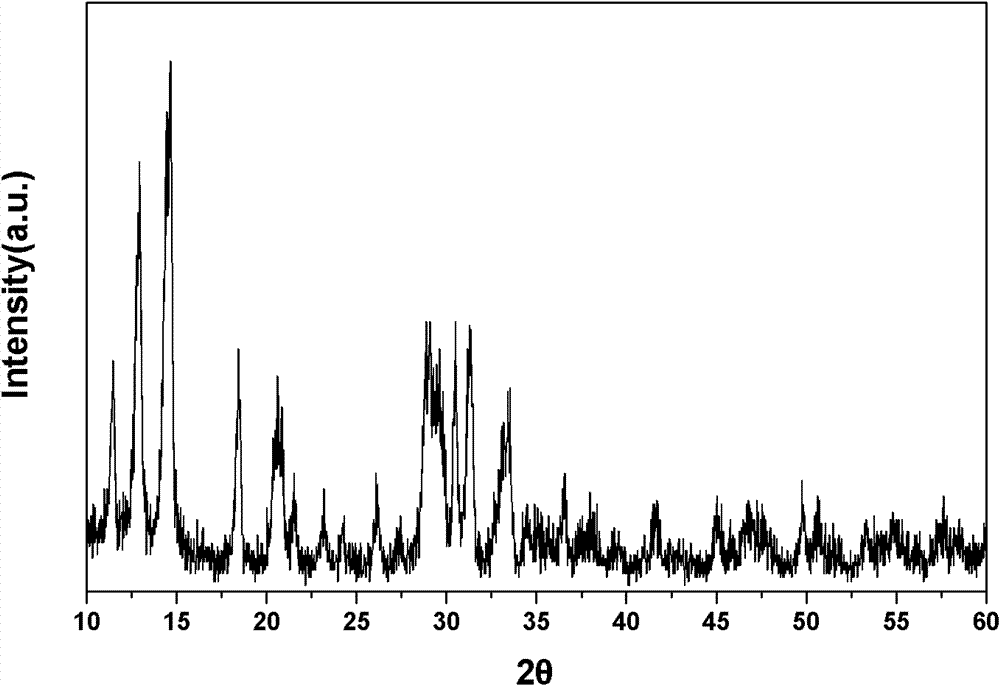

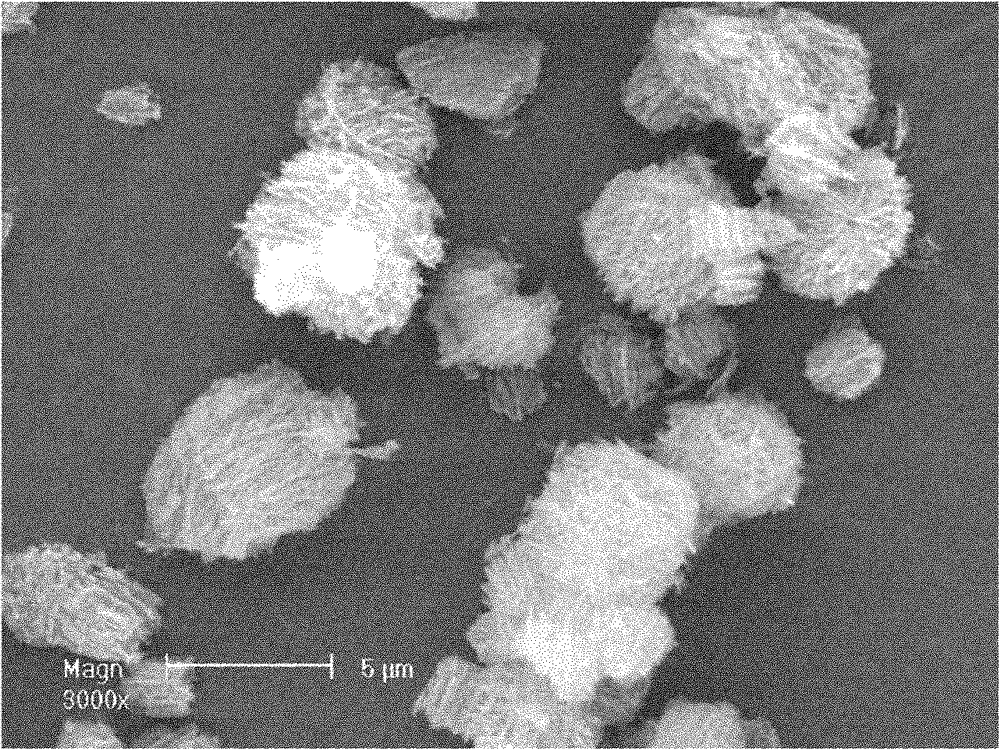

[0024] The slurry is aged in the reaction liquid, and the aging temperature is controlled at 70-90°C. After aging for 10 hours, filter the slurry, wash the filter cake with deionized water, and then filter until the filtrate is neutral. Dry the filter cake in a blast drying oven at 80°C for 6-8 hours to obtain basic ammonium ferric phosphate particles. The specific surface area of the particles reaches 97m 2 / g, pass the SEM test (such as figure 2...

Embodiment 2

[0027] Solution preparation: Prepare 2mol / L ferric nitrate aqueous solution and ammonium phosphate aqueous solution respectively.

[0028] With above-mentioned two kinds of solutions according to molar ratio Fe:P=1:1.6, join in the reaction vessel under stirring respectively at the same time, reaction temperature is controlled at 60-80 ℃, after dropping, adjust with ammonia water (concentration is 20%) pH value, until the pH value is 1, to obtain amorphous basic iron ammonium phosphate slurry.

[0029] The slurry is aged in the reaction liquid, and the aging temperature is controlled at 60-80°C. After aging for 12 hours, filter the slurry, wash the filter cake with deionized water, and then filter until the filtrate is neutral. Dry the filter cake in a blast drying oven at 80°C for 12 hours to obtain basic ferric ammonium phosphate. Particle specific surface area reaches 88m 2 / g, as can be seen from the SEM results, the product is a spherical petal-like particle (result and...

Embodiment 3

[0032] Solution preparation: Dissolve ferric nitrate and ferric citrate in water to prepare an iron-based mixed solution with an iron concentration of 1mol / L. Dilute the phosphoric acid solution with deionized water to prepare a phosphoric acid solution with a concentration of 1mol / L. Adjust the pH value of the phosphoric acid solution to 5-7 with ammonia water (concentration: 25%).

[0033] The above two solutions are added to the reaction vessel under stirring at the same time according to the molar ratio Fe:P=1:1.3, and the reaction temperature is controlled at 60-80°C. pH value, until the pH value is 2, to obtain amorphous basic ammonium ferric phosphate slurry.

[0034] The slurry is aged in the reaction liquid, and the aging temperature is controlled at 60-80°C. After aging for 12 hours, filter the slurry, wash the filter cake with deionized water, and then filter until the filtrate is neutral. Dry the filter cake in a blast drying oven at 80°C for 12 hours to obtain b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com