Novel antibacterial yarn manufacture process

A production process and yarn technology, which is applied in the production process of new antibacterial yarns, can solve the problems of slow release rate of silver ions, difficult processing, high processing costs, etc., and achieve remarkable antibacterial health care functions, broad application markets, and antibacterial efficacy long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

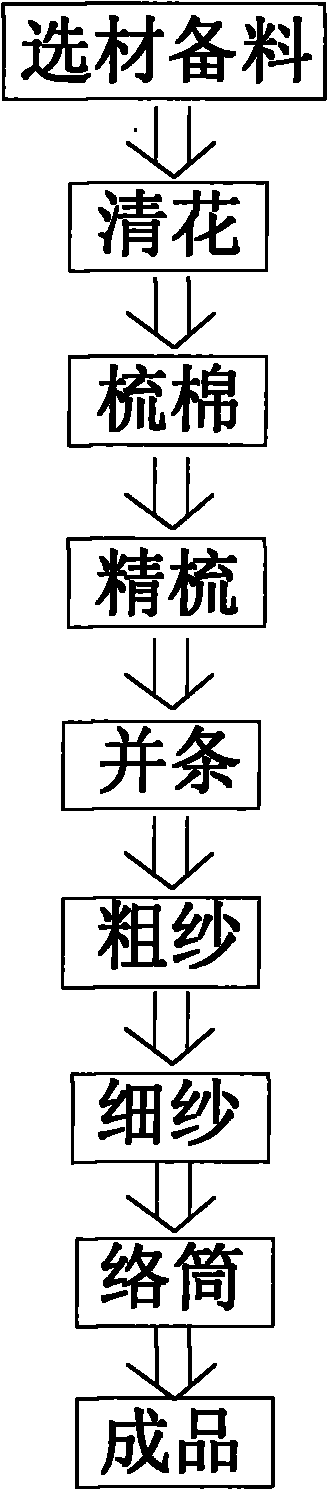

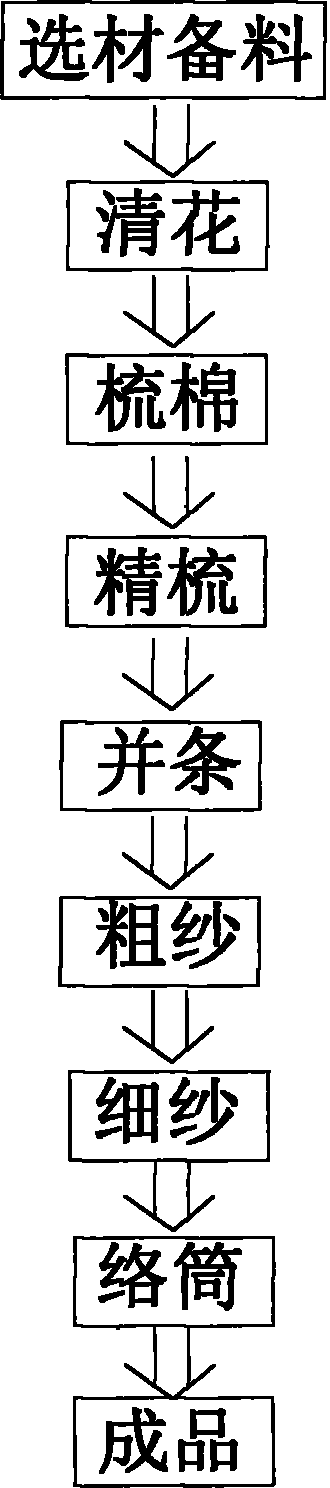

Image

Examples

Embodiment 1

[0022] a) Material selection and preparation, the antibacterial yarn is composed of nano-bamboo carbon fiber, nano-silver fiber and natural fabric fiber, and its percentage content ratio is: nano-bamboo carbon fiber 20, nano-silver fiber 10, and natural fabric fiber 70;

[0023] b) Cleaning, separate the nano-bamboo carbon fiber and nano-silver fiber into rolls, wherein the nano-bamboo charcoal fiber has a relatively large proportion, so it should be lightly beaten and combed to fully open;

[0024] c) Carding, set the licker-in speed to 840r / min, properly reduce the licker-in speed, reduce the impact of the licker-in on the cotton layer, reduce neps, and improve yarn quality. The cylinder speed is 360r / min, and the cover plate The speed is 220mm / min, the doffer speed is 22r / min, and the nano-bamboo carbon fiber and nano-silver fiber are made into a uniform sliver through the pressing roller and coiling device;

[0025] d) Combing, set the roller gauge to 5×10, the diameter of...

Embodiment 2

[0031] a) Material selection and preparation, the antibacterial yarn is composed of nano-bamboo carbon fiber, nano-silver fiber and natural fabric fiber, and its percentage content ratio is: nano-bamboo carbon fiber 25, nano-silver fiber 10, natural fabric fiber 65;

[0032] b) Cleaning, separate the nano-bamboo carbon fiber and nano-silver fiber into rolls, wherein the nano-bamboo charcoal fiber has a relatively large proportion, so it should be lightly beaten and combed to fully open;

[0033] c) For carding, set the licker-in speed to 860r / min, properly reduce the licker-in speed, reduce the impact of the licker-in on the cotton layer, reduce neps, and improve yarn quality. The cylinder speed is 360r / min. The board speed is 220mm / min, the doffer speed is 22r / min, and the nano-bamboo carbon fiber and nano-silver fiber are made into a uniform sliver through the pressing roller and coiling device;

[0034] d) Combing, set the roller gauge to 5×10, the diameter of the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com