Method for compounding anchor rod by geotextile reinforcing

A composite bolt and geotextile technology, applied in the field of engineering, can solve the problems of slurry loss, difficult to form anchors, and difficult to anchor, and achieve the effect of improving the pullout resistance of the bolt, reducing construction costs and saving cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Practical cases in 2# and 3# landslide control projects of Yangchun New Iron and Steel Co., Ltd.

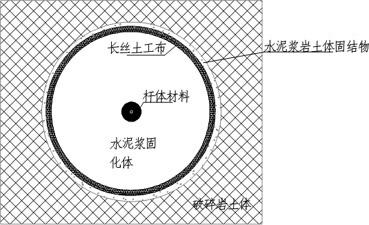

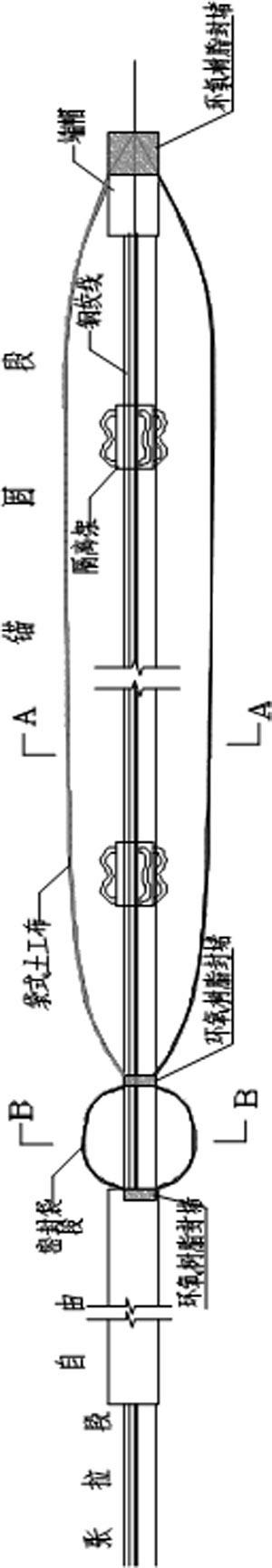

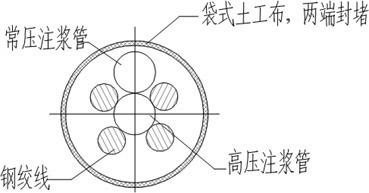

[0018] according to Figure 1-4 Shown, a kind of geotextile reinforced composite anchor method, its steps are as follows:

[0019] ① Hole forming: use YG-60 bolter drilling rig, adopt down-the-hole hammer eccentric follow pipe drilling process to form holes; after reaching the design hole depth of 20m, take out the drill pipe and evacuate the drilling rig;

[0020] ②Anchor rod production: The anchor rod uses 5 bundles of f ptk = 1860MPa high-strength low-relaxation unbonded steel strand, the total length of the anchor body is 21.0m, and the length of the anchor section is 8.0m; the free section of the anchor is separated from the anchor section by a sealed bag, and the anchor section is installed bag geotextile;

[0021] ③Anchor installation: place the prepared geotextile composite anchor in the borehole, and pull out the follow-up casing;

[0022] ④ Grouting: First, g...

Embodiment 2

[0026] Practical case of Yangchun New Iron and Steel's manual unloading trough and double dumper system for deep foundation pit support

[0027] according to Figure 1-4 Shown, a kind of geotextile reinforced composite anchor method, its steps are as follows:

[0028] ① Hole forming: use MD-60A bolter drilling rig, and use the down-the-hole hammer concentric drilling process to form holes; after reaching the design hole depth of 28m, take out the drill pipe and evacuate the drilling rig;

[0029] ②Anchor rod production: the anchor rod adopts 4 beams f ptk =1860MPa high-strength low-relaxation unbonded steel strand, the total length of the anchor rod body is 28.0m, and the length of the anchoring section is 16.0m; bag-type geotextiles are installed in the anchoring section;

[0030] ③Anchor installation: place the prepared geotextile composite anchor in the borehole, and pull out the follower pipe;

[0031] ④ Grouting: Control the grouting pressure at 1.0MPa and the slurry f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com