Double-column sailboard type wind turbine

A wind turbine and sailboard technology, applied in the field of wind power generators, can solve the problems of wide blades, heavy design, low strength, etc., and achieve the effect of large radius of action and good effect of wind force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

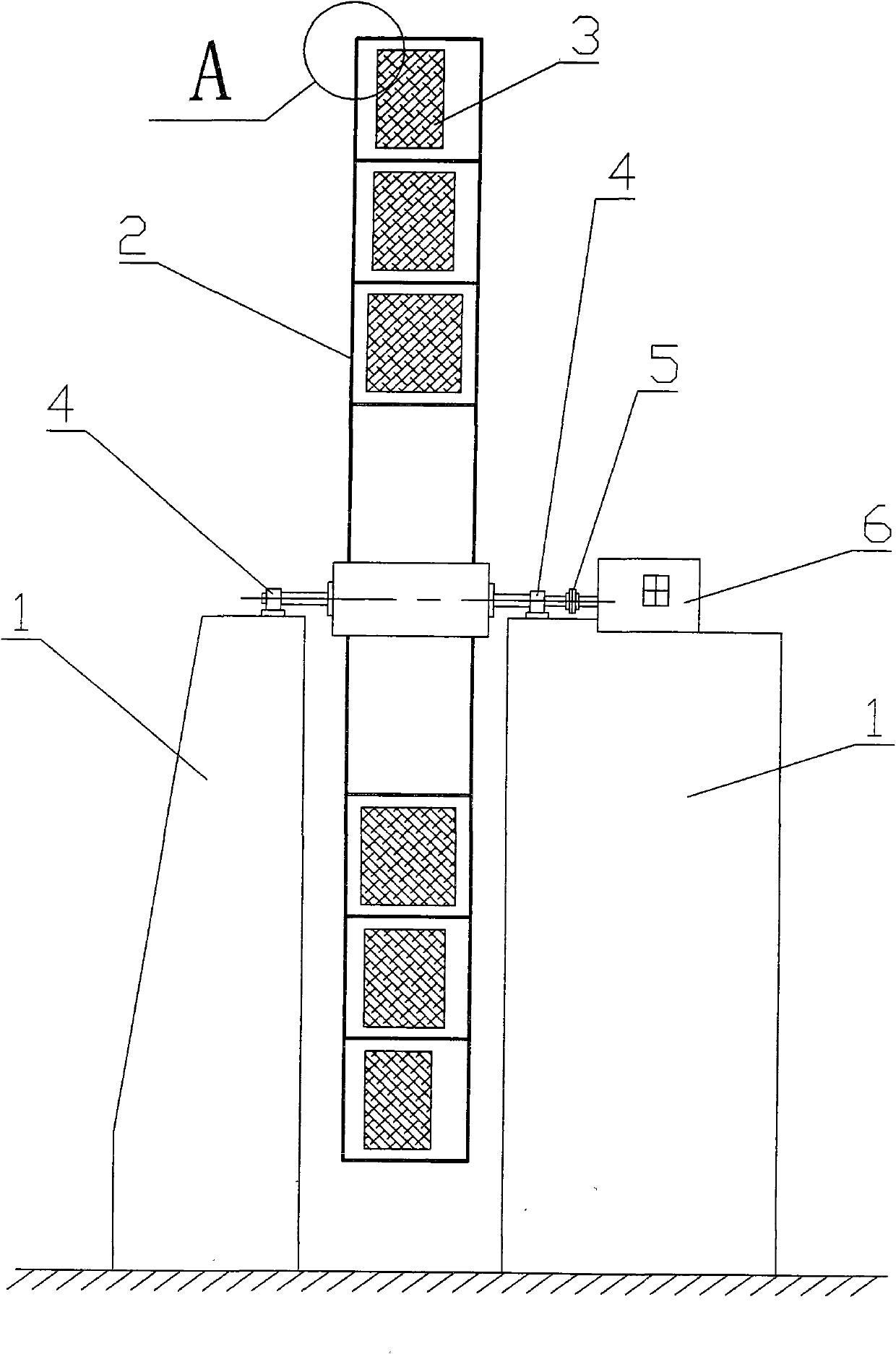

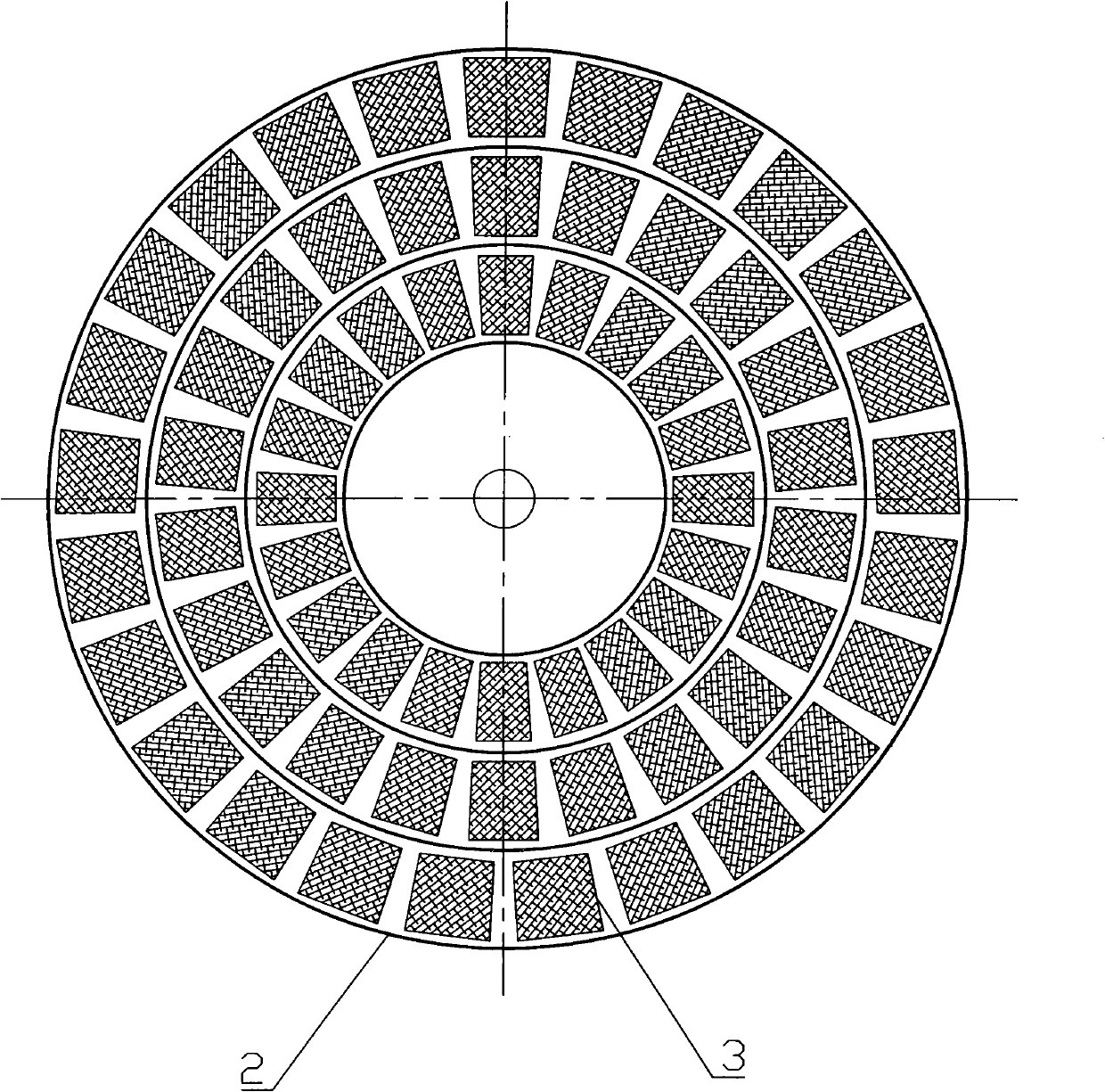

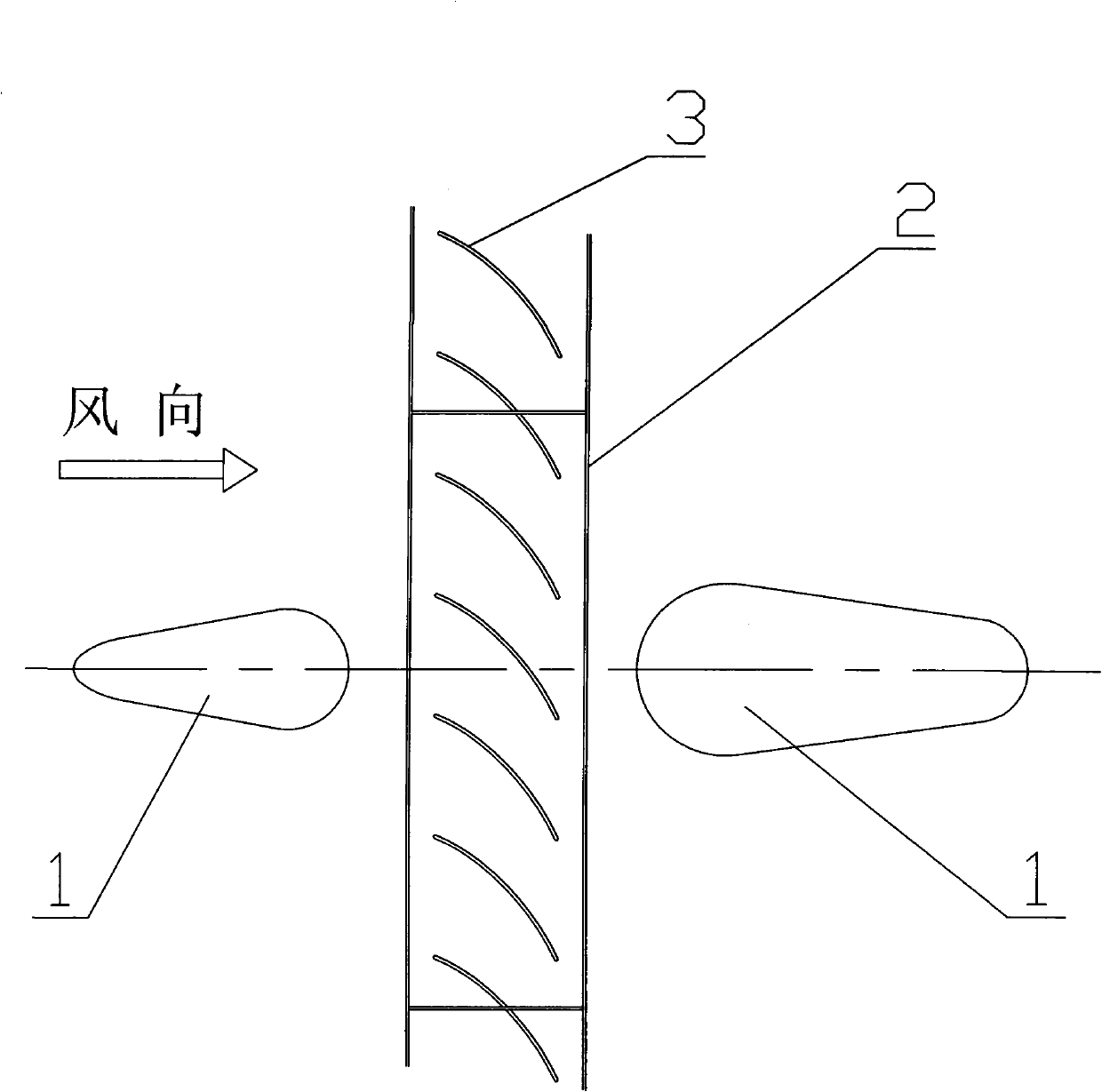

[0014] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. as attached figure 1 , 2 Shown, weld the metal wheel frame (2) of a circular frame structure with steel pipe. as attached Figure 5 As shown, the steel pipe (8) is penetrated and embedded in the sail board along the edge of the sail board (3), and the two ends are welded with end thin rods (9) to block the two ends of the steel pipe to prevent rainwater from flowing into the steel pipe inner wall. On the other hand, the diameter of the thin rod (9) at the end is smaller than that of the steel pipe (8) to form a shoulder, thereby preventing the steel pipe from loosening and stringing in the sailboard. The steel pipe (8) runs through the entire sailboard (3), and plays the role of skeleton and reinforcement for the sailboard. The two ends (9) of the steel pipe (8) stretch out and are fixed on the metal wheel frame (2). as attached f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com