Media interface construction system based on LED (Light Emitting Diode) and optical media

An optical medium and interface technology, applied in optics, optical components, instruments, etc., can solve the problems of complex manufacturing process and control system, glare, high brightness of screen surface, increase circuit complexity, easy maintenance and replacement, and difficult maintenance. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

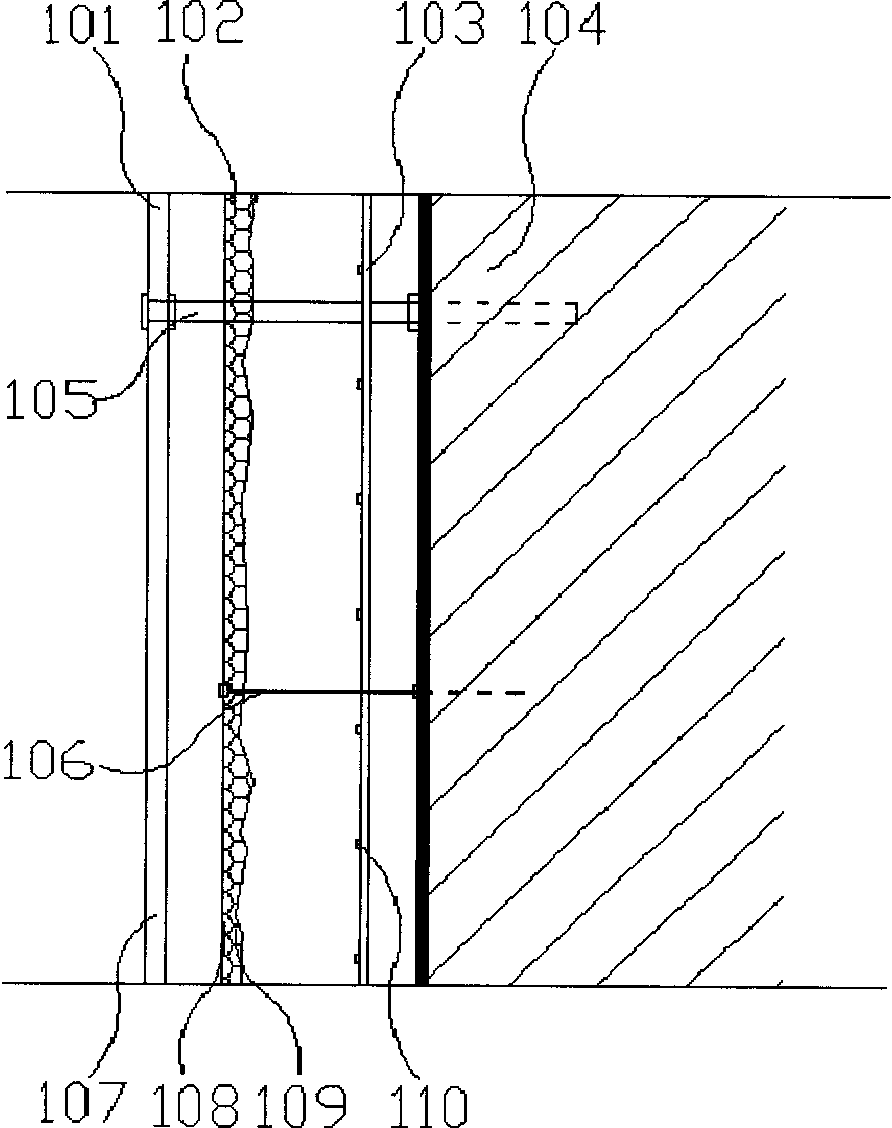

[0029] Such as figure 2 As shown, the construction system of this embodiment is composed of a homogeneous LED base layer 101, a plastic film optical medium layer 102 and a frosted glass image bearing layer 103: the homogeneous LED base layer 101 is composed of LED light-emitting lattices 110 with a pitch of 60mm×60mm Composition, the power of the LED light-emitting dot matrix 110 is 70W / m2, the refresh frequency is ≥1000Hz, and the light-emitting angle of the LED (horizontal viewing angle and vertical viewing angle) is both ≥90 degrees, and then the brightness and color change of the LED light-emitting dot matrix are controlled by the LED controller The plastic film optical medium layer 102 is laid together by a white translucent plastic film and a black plastic film 109, and the black and white texture can be determined according to the artistic effect expressed, and its area should be consistent with the coverage area of the LED base layer; frosted glass The image bearing...

Embodiment 2

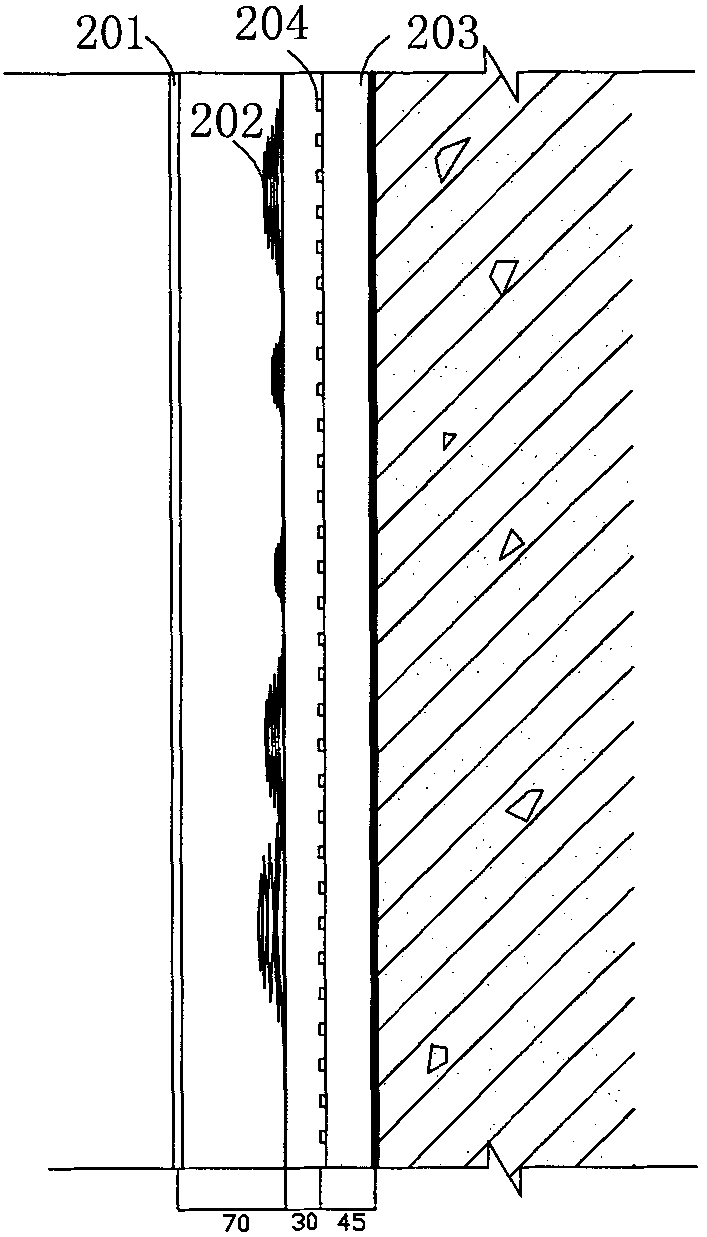

[0032] Such as image 3 As shown, the homogeneous LED base layer 204 of this embodiment is composed of LED light-emitting lattices with a pitch of 40mm×40mm. Vertical viewing angle) ≥ 120 degrees; then the brightness and color change of the LED light-emitting dot matrix are controlled by the LED controller. The optical medium layer 202 is pressed with a tinplate engraving die, and the optical medium layer is 3 cm away from the LED base layer and 7 cm away from the surface image bearing layer. The tinplate itself is opaque. After engraving, the center of the pattern protrudes 0-2cm to form a gap. The light is emitted from the back through the gap, and is refracted and reflected between the optical medium layer 202 and the image bearing layer 201 for many times, and finally on the frosted glass. It has a rose-like pattern on it. Ripple-like patterns vary in size and density in the plane arrangement, controlling the basic layout of the surface image. The radius of the large ci...

Embodiment 3

[0034] Such as Figure 4 As shown, the media interface construction system of this embodiment is composed of a homogeneous LED base layer 303, a tin foil optical medium layer 302, and a translucent frosted glass image bearing layer 301: the homogeneous LED base layer 303 is made of LEDs with a spacing of 20mm×20mm. Composed of dot matrix 304, the power of LED light-emitting dot matrix 304 is 600W / m2, the refresh frequency is ≥1920Hz, and the light emitting angle of LED (horizontal viewing angle and vertical viewing angle) is both ≥120 degrees, and then the brightness of LED light-emitting dot matrix is controlled by the LED controller , color change; the tinfoil optical medium layer 302 is to wrap the 2cm wide hard paper tape with tinfoil, and surround it into several irregularly shaped figures, and connect them as a whole with staples to form a pattern unit, each The area of each irregular figure is controlled at 0.01m2-0.04m2; the frosted glass image bearing layer 301 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com