Energy-saving environment-friendly plastic rolling oven

An energy-saving, environmentally friendly, rotational molding technology, applied in the direction of coating, etc., can solve the problems of incomplete combustion of combustible gas or fuel oil, waste of fuel, dirty heating chamber and mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

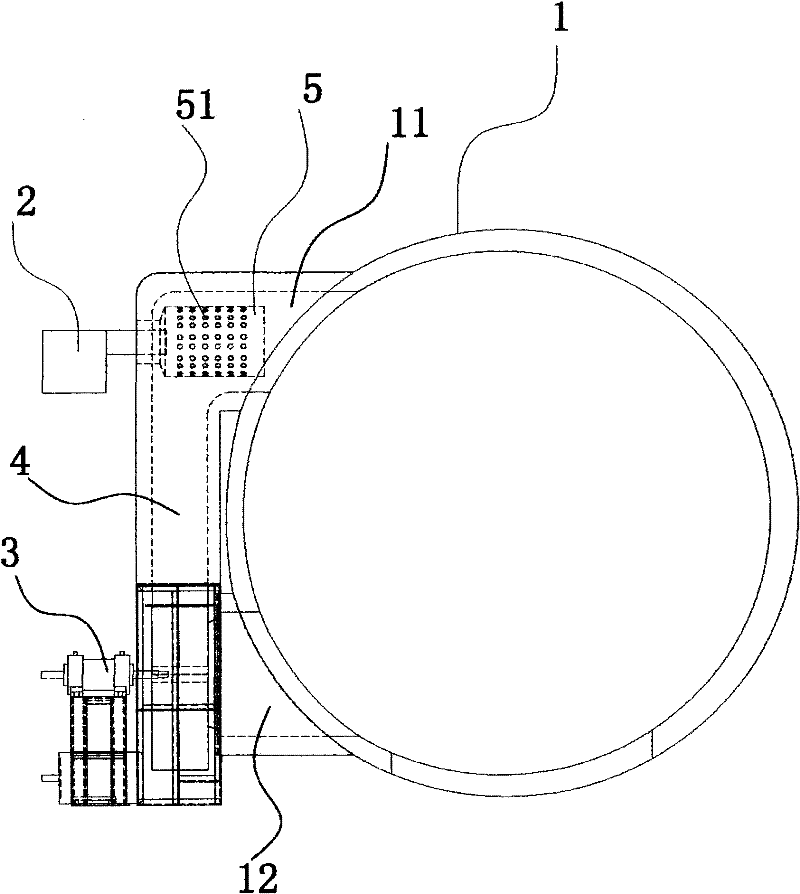

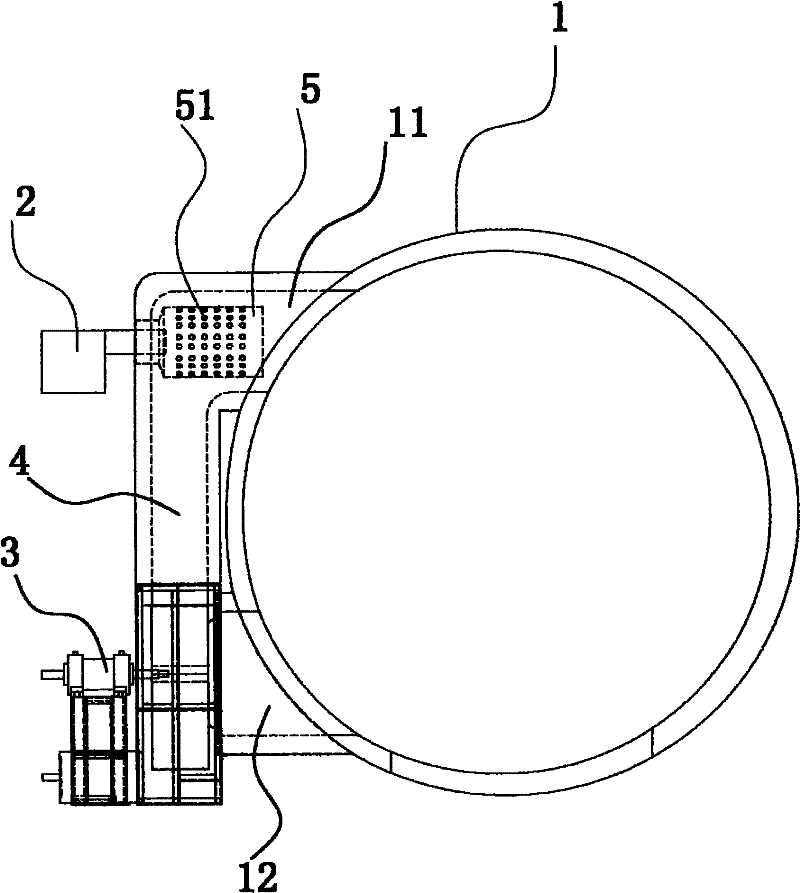

[0019] Such as figure 1 As shown, this energy-saving and environment-friendly rotomolding oven includes a burner 2, a centrifugal circulating fan 3 and a cylindrical heating chamber 1. The heating chamber 1 is placed horizontally on the ground, and the front and rear ports are opened or closed through the heating chamber door. , when the heating chamber door is closed, a fully enclosed heating chamber 1 is formed. A group of air outlet duct 11 and air inlet duct 12 are arranged on the inner wall of the heating chamber 1, the air outlet duct 11 is located directly above the air inlet duct 12, and the air outlet duct 11 and the air inlet duct 12 communicate with each other through an air duct 4, An air circulation channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com