Method for producing mounting-frame aluminium sections, aluminium section and mounting frame with aluminium sections

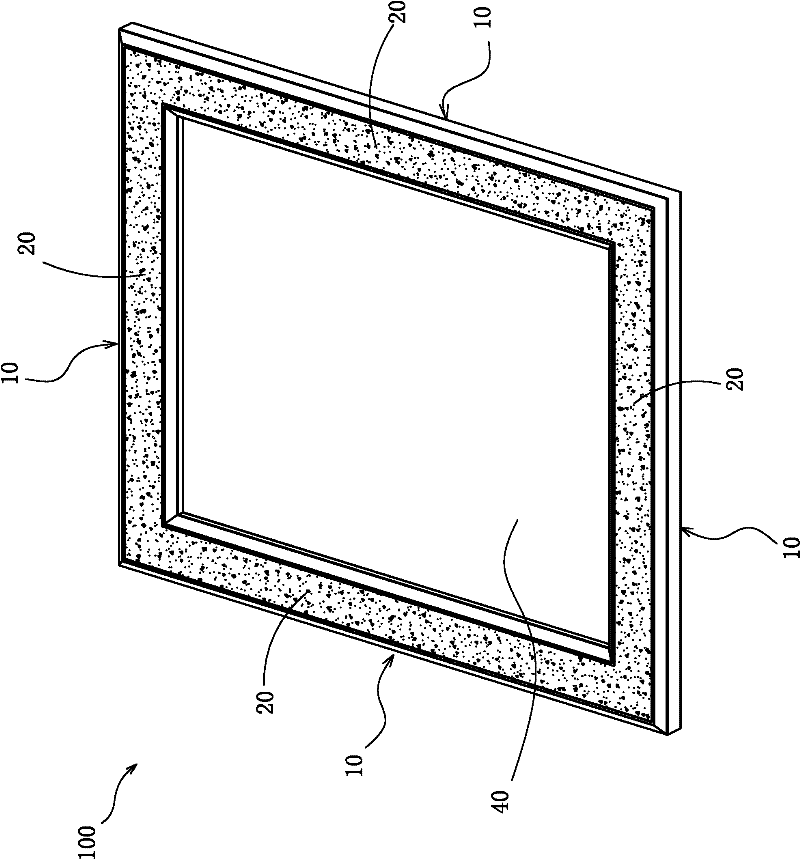

A production method and technology of aluminum profiles, which can be used in pasting, decorative art, etc., can solve the problems of single decorative effect and inability to form shiny effects, etc., and achieve the effect of easy disassembly and assembly and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

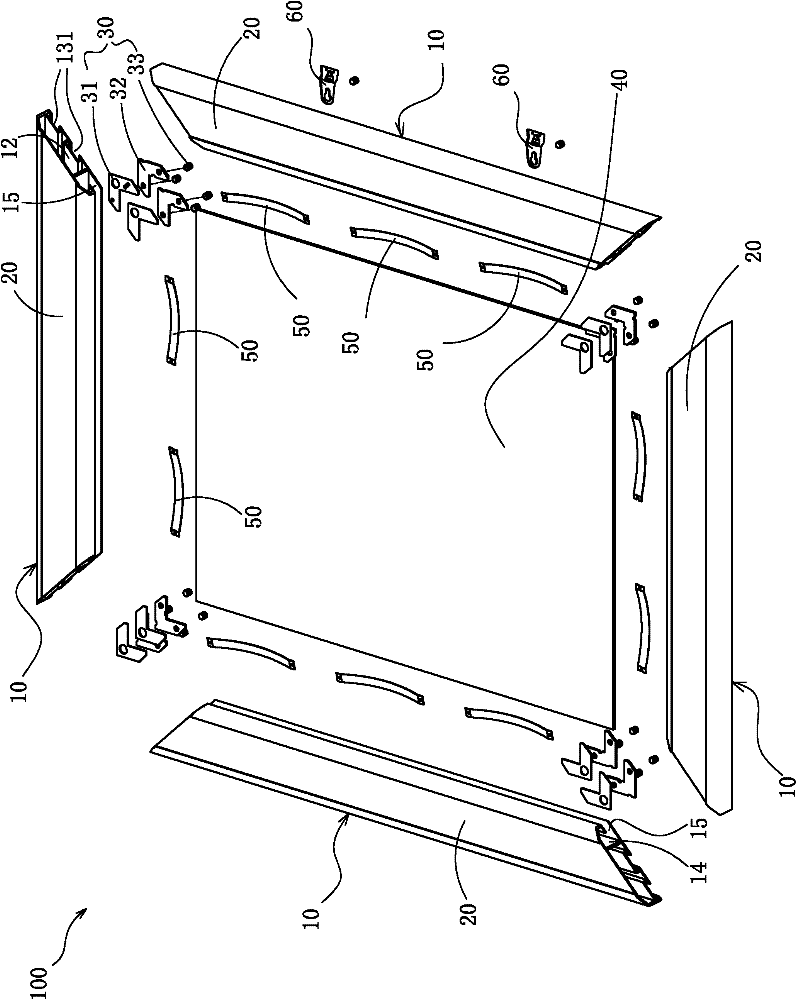

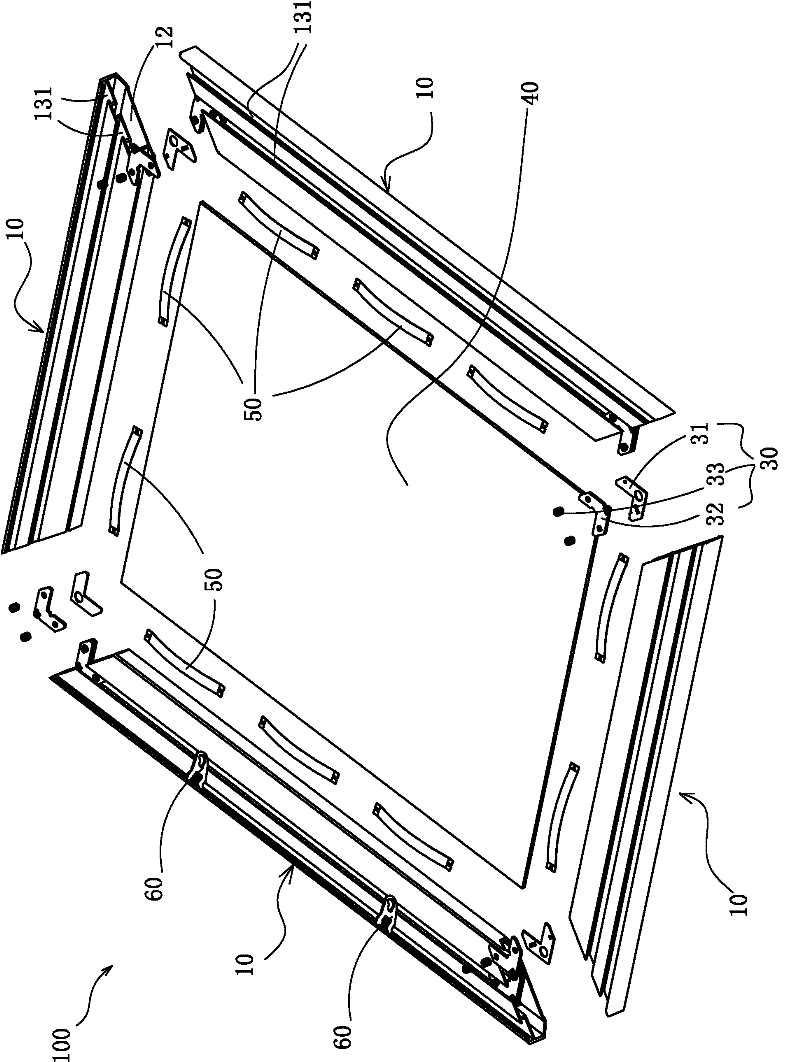

[0021] Produce the aluminum profile of the mounting frame of this specific embodiment, preferably aluminum material 6063T5, by extrusion molding, obtain such as Figure 4 As shown in the cross-section of the aluminum profile, the profile 10 has a cavity 12 extending longitudinally, and on the periphery of the cavity, the surface of the aluminum profile includes the front 11 (the front of the outer surface of the aluminum profile refers to the formed Frame rear front, such as figure 2 shown) and the opposite back 13; the front 11 of the profile 10 outer surface is provided with a groove 111 extending longitudinally; the back is provided with two T-shaped grooves parallel to each other and extending longitudinally as a connection Groove 131; And on a connection surface 14 between described front and the back side, then be provided with the mounting thing inserting groove 15 that extends longitudinally, the concrete structure of this mounting matter inserting groove 15 is: the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com