Automatic stowage device of substitutive loading sliding sheet of goods transport tray

A technology of pallets and slides, which is applied in the field of automatic loading devices for slides loaded on cargo transfer pallets, can solve the problems of low work efficiency and unfavorable continuous automatic operation, etc., and achieve the effect of simple structure, low cost, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

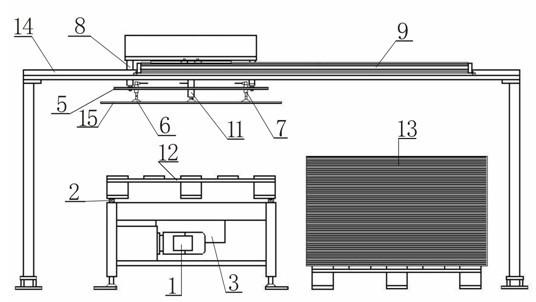

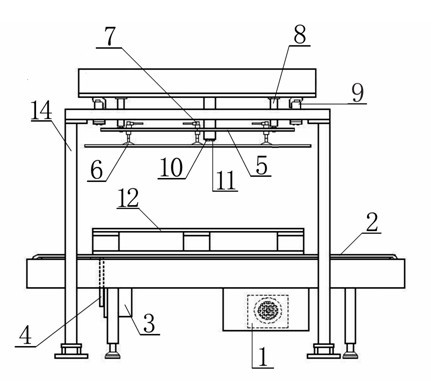

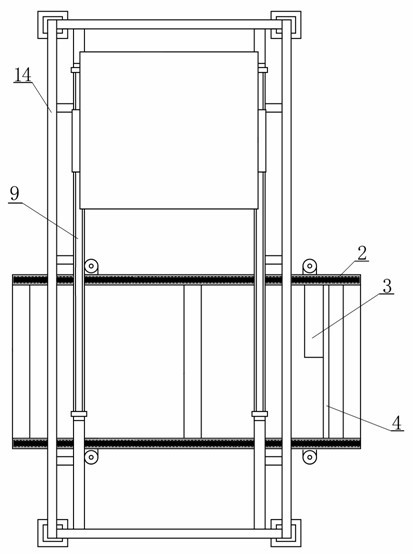

[0010] The present invention is further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teachings of the present invention falls within the protection scope of the present invention.

[0011] like Figure 1~Figure 3 As shown, the present invention includes a motor 1, a tray conveying device 2, a cylinder 3, a pneumatic baffle 4, a suction device 5, a negative pressure suction cup 6, an air pressure distribution pipe 7, a telescopic rod 8, a sliding track 9, a video detection device 10 and a laser The distance measuring device 11; the pallet conveying device 2 is driven by the motor 1, the pneumatic baffle 4 and its driving cylinder 3 are located under the pallet conveying device 2; the video detection device 10 and the laser distance measuring device 11 are jointly arranged on the suction device 5 , the suction device 5 is provided with an air pressure distribution pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com