Reversible suspended basket wheel type travelling system and method

A basket wheel and variable technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of difficult control of the running direction of the hanging basket, slow running speed, unfavorable safe use of the hanging basket structure, etc., to achieve power-driven automation Control, reasonable force, and ensure the effect of anti-overturning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

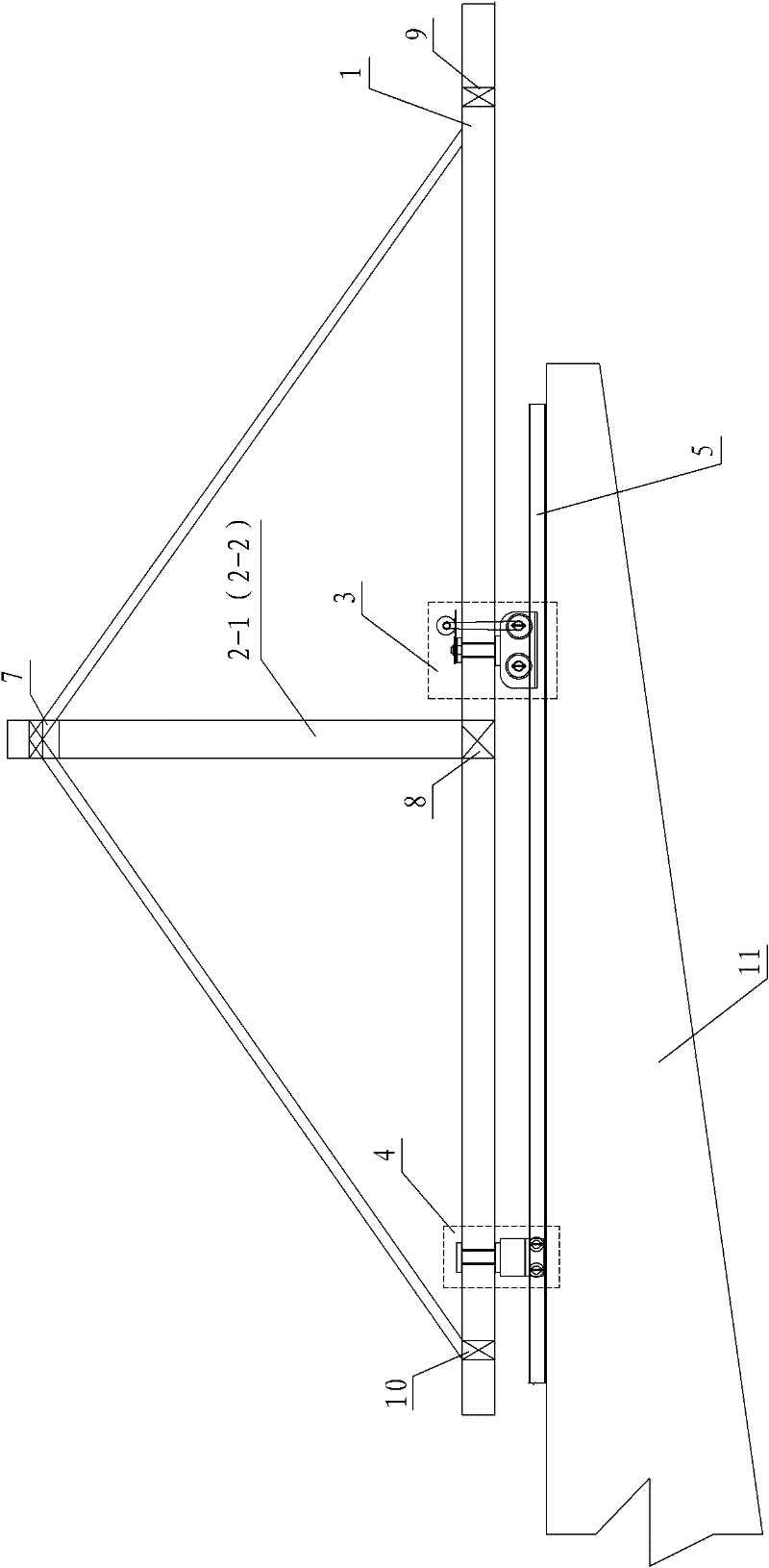

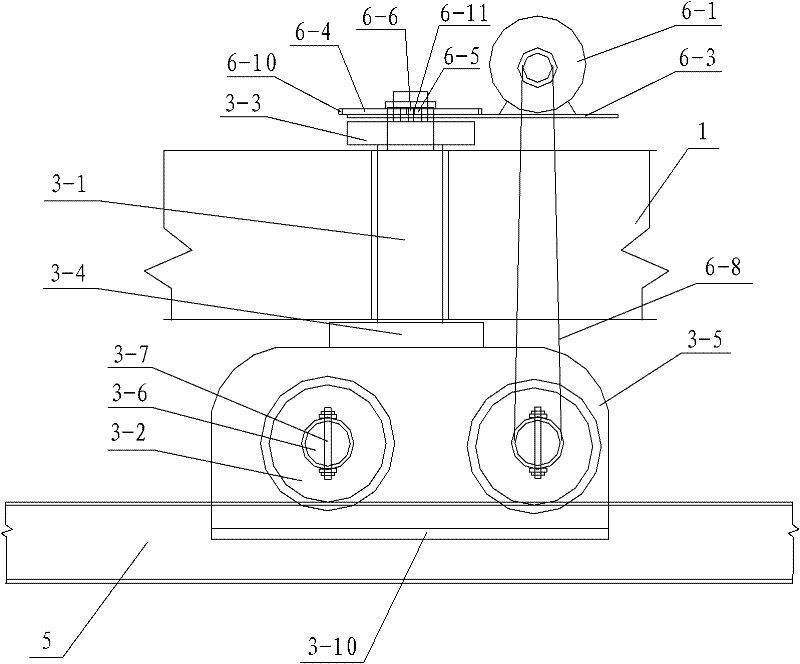

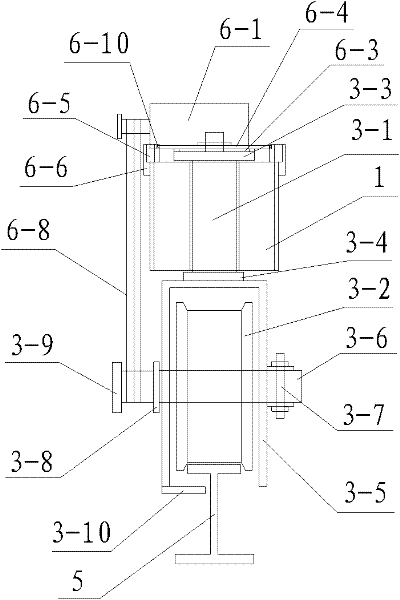

[0060] Such as Figure 1-Figure 6 As shown, the variable direction hanging basket wheeled walking system of the present invention includes two hanging basket longitudinal beams 1 and respectively located in front of the lower end of the left central column 2-1 and in front of the lower end of the right central column 2-2. The front running device 3, the two rear running devices 4 arranged on the longitudinal beam 1 of the hanging basket and respectively located in front of the left end of the rear cross beam 10 of the hanging basket and the front of the right end of the rear cross beam 10 of the hanging basket, provide two front running devices 3 and two rear running devices. The two I-shaped steel rails 5 for the running device 4 and the running power device for driving the hanging basket are characterized in that: the front running device 3 includes a front running steering shaft 3-1 and a plurality of front running wheels 3-2 , the bottom end of the front travel direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com