V-type pier steel-structure bridge folding and ejecting system

A rigid-frame bridge and bridge pier technology, which is applied in the field of V-shaped pier rigid-frame bridge closing and pushing system, can solve the problems of high pier stiffness, failure to achieve the effect of a bridge, restricting the development of the span of a continuous rigid-frame bridge, etc. Simple, improve long-term mechanical performance, prevent falling beams and lateral buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

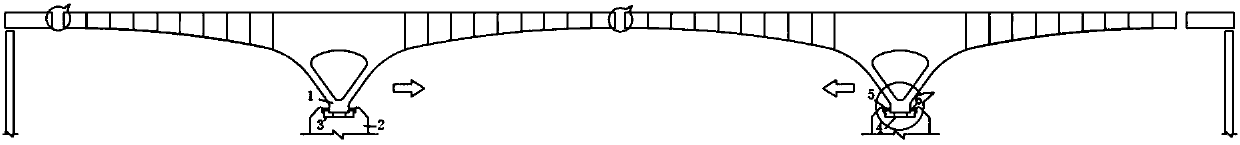

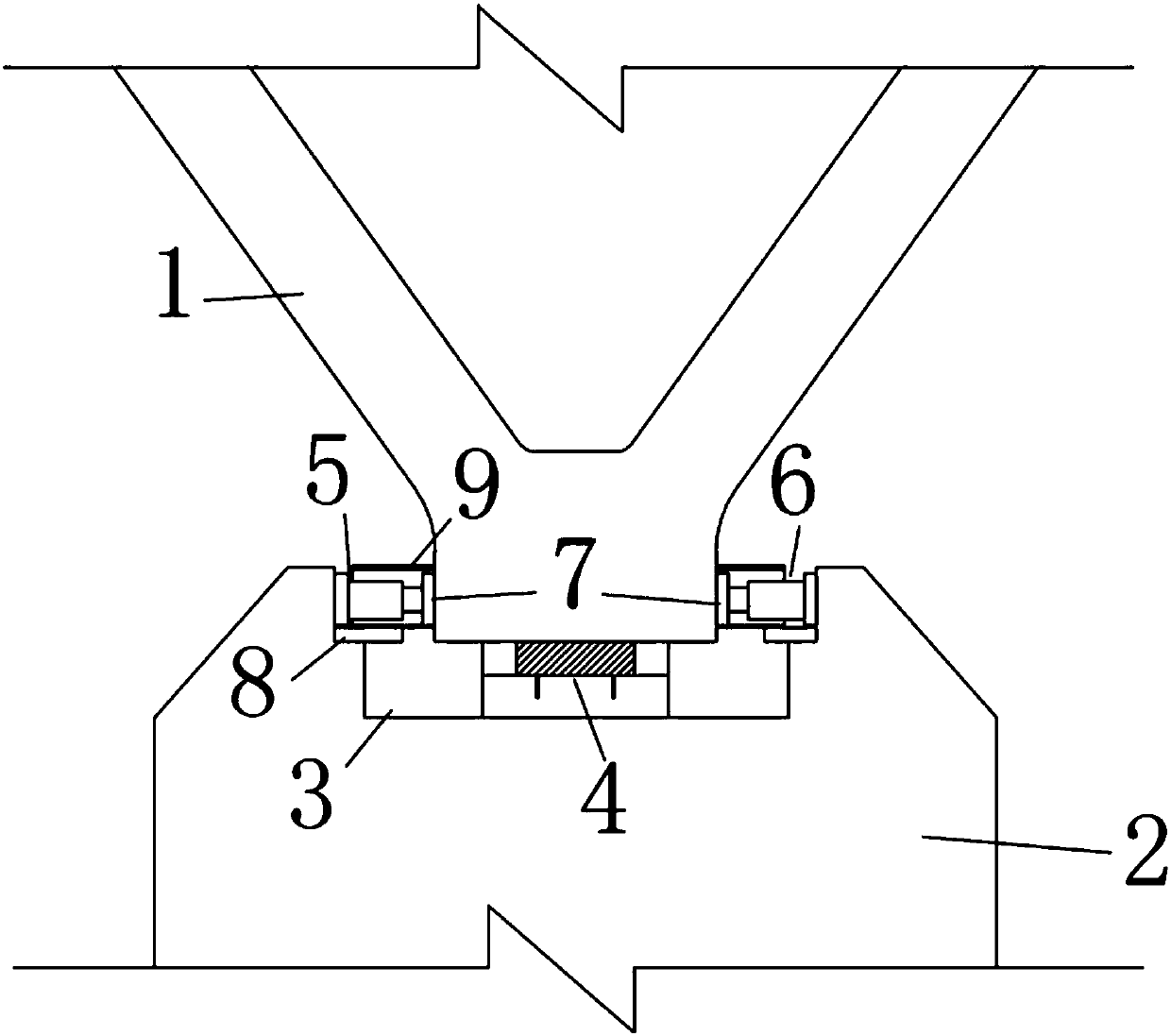

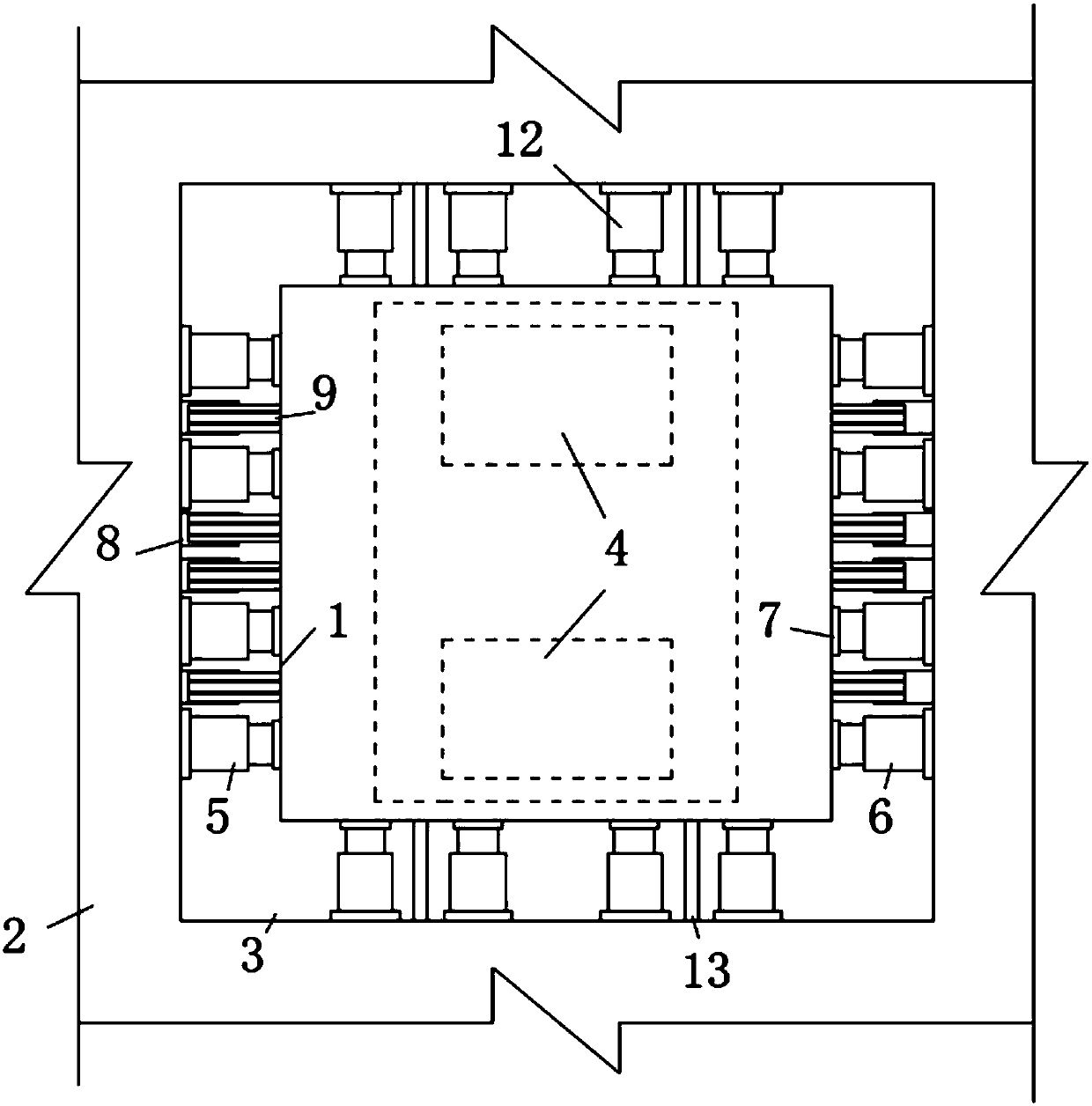

[0034] A V-shaped pier rigid frame bridge closing and pushing system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] like Figure 1 to Figure 5 As shown, a V-shaped pier rigid frame bridge closing and pushing system of the present invention includes a pier 1 and a cap 2, a groove 3 is provided on the top of the cap 2, and two spherical steel supports are provided at the bottom of the groove 3. The bottom of pier 1 is supported on spherical steel bearings; a plurality of limit jacks 5 and push jacks 6 are arranged longitudinally between pier 1 and cap 2, and push jacks 6 and limit jacks 5 are located on opposite sides of pier 1. side; between the bridge pier 1 and the cap 2, a plurality of transverse jacks 12 are respectively arranged on both sides, and a plurality of I-beams 9 are embedded in the bottom of the pier 1, and the I-beams 9 are located between two limit jacks 5 or between two Between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com