Pressure stabilizing device and pressure stabilizing method for pneumatic equipment

A technology of voltage stabilizer and equipment, applied in mechanical equipment, gas/liquid distribution and storage, pipeline system, etc., can solve the problems of increasing labor intensity of employees, increasing investment, insufficient gas supply pressure, etc., to avoid product quality and output The effect of lowering, reducing labor intensity and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions provided by the present invention will be further described below in conjunction with the examples.

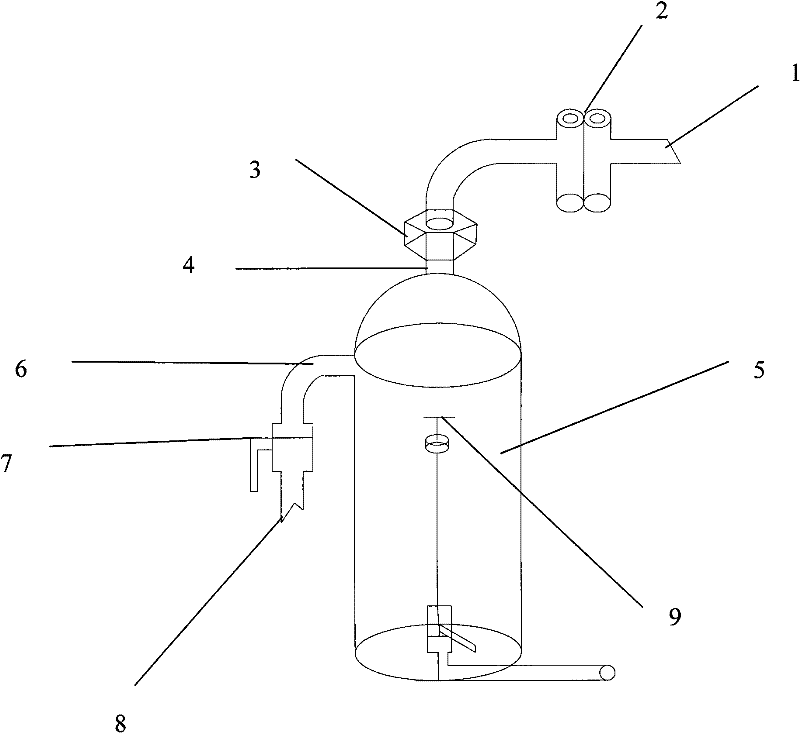

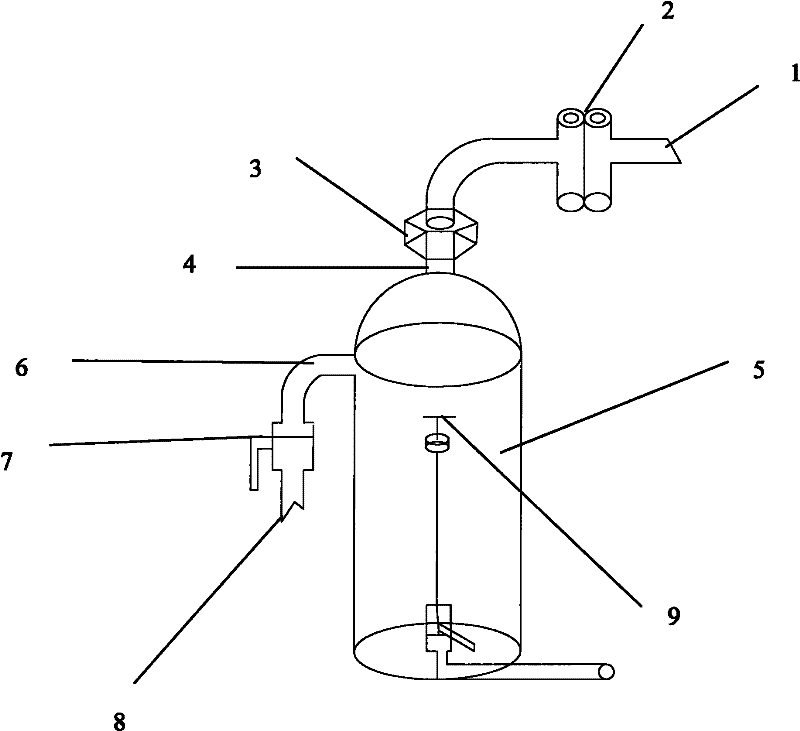

[0022] Such as figure 1 As shown, the compressed air storage tank 5 in the device of the present invention is connected to the compressed air filter 2 through the compressed air intake pipe 1, and then connected to the compressed air supply pipeline 8, installed at the pneumatic equipment of the production line, and stored in the compressed air An air intake interface 4 is provided between the tank 5 and the compressed air filter 2 for connecting the mimeograph 3 and the compressed air intake pipe 1 . After the compressed air enters the air storage tank 5 through the compressed air inlet pipe 1, the air outlet port 6 communicates with the compressed air pipeline through the air supply valve 7, and the air supply valve is in the normally open state during the production stage. A section of pipeline for dredging compressed air (that is, the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com