Dry dust removal system for converter primary flue gas ultra-low emission and smoke plume elimination

A technology for dry dust removal and flue gas, applied in the field of dust removal systems, can solve the problems of prominent smoke plume, corrosion of gas pipelines and equipment, and explosion of electrostatic precipitators, to eliminate smoke plume problems, reduce corrosion, and eliminate water vapor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

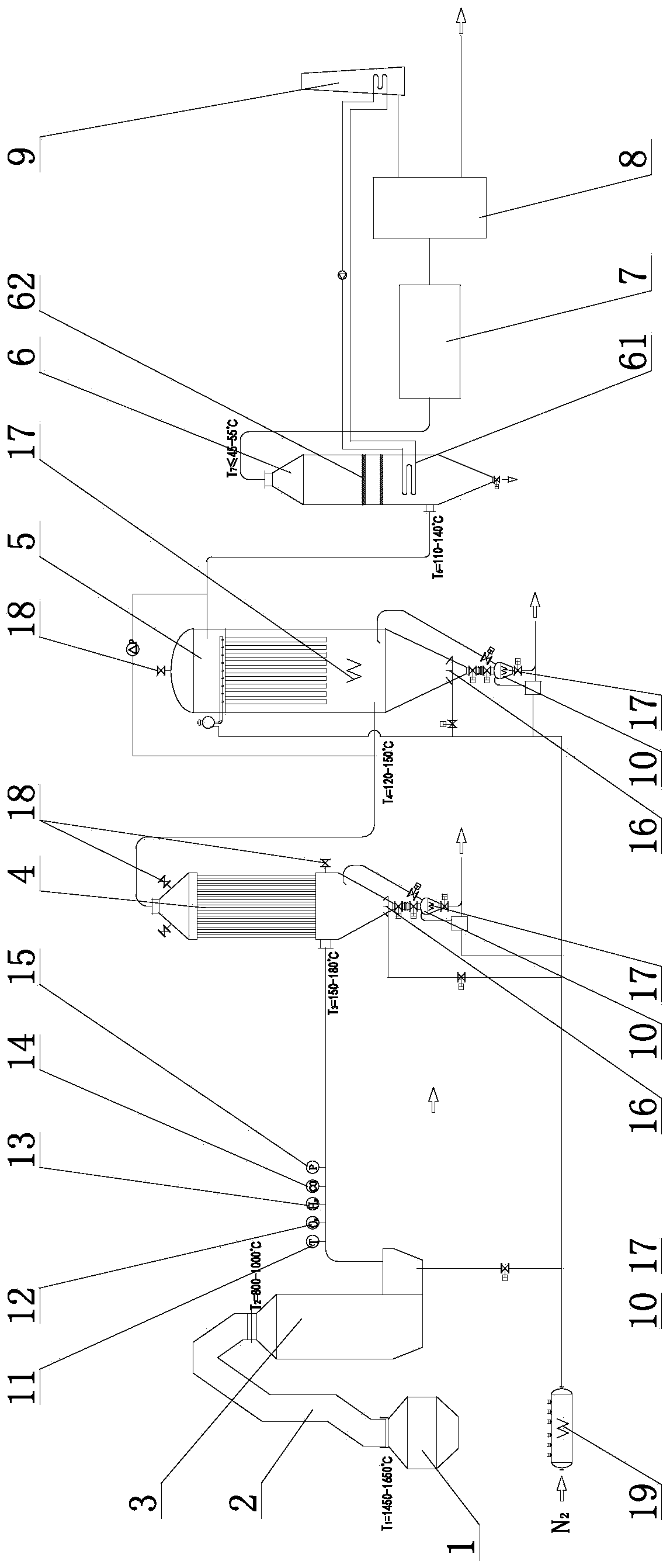

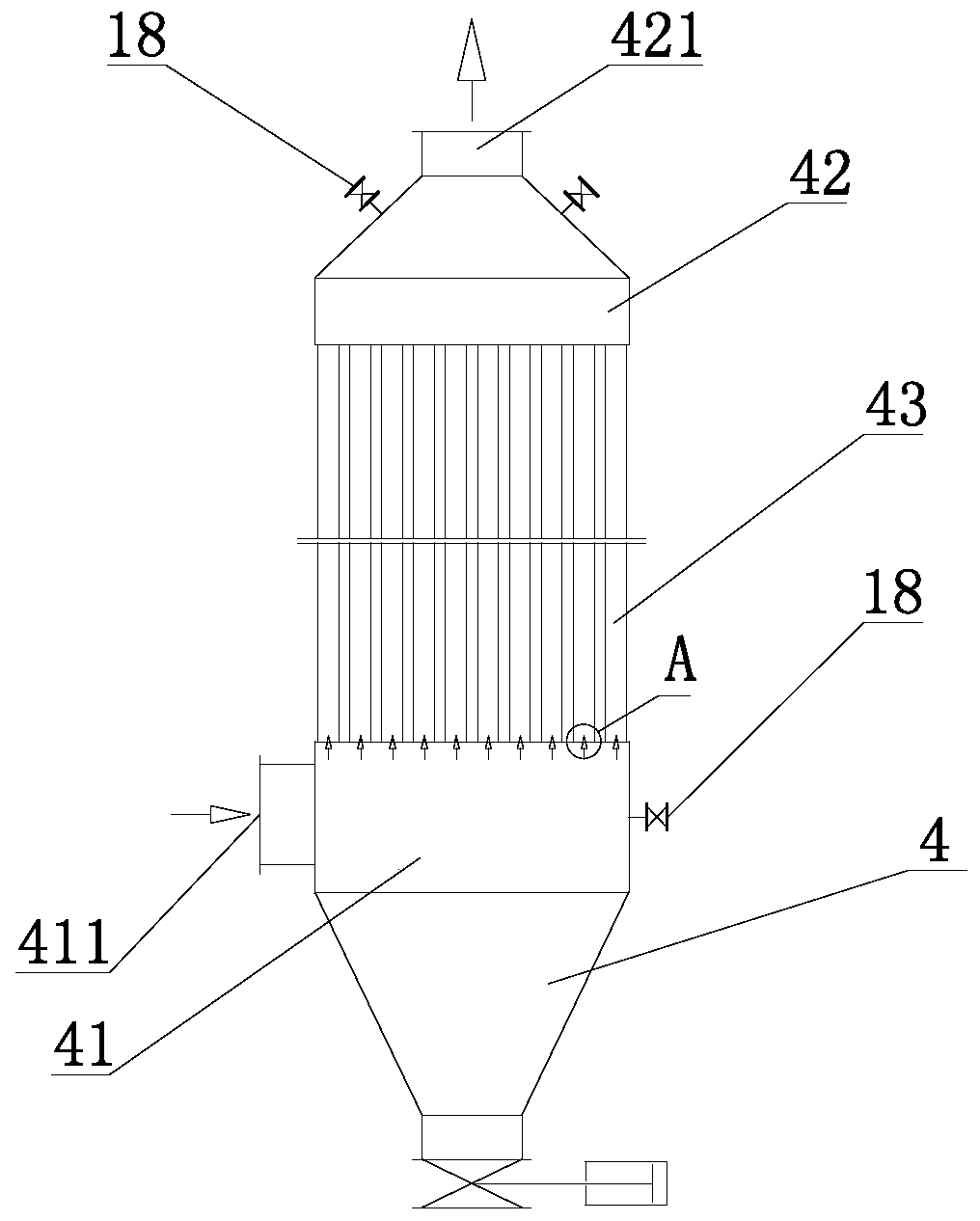

[0041] Such as Figure 1 to Figure 3 As shown, the dry dedusting system for converter primary flue gas ultra-low emission and smoke plume elimination in this embodiment, converter 1 is connected to vaporization cooling flue 2 through movable fume hood and cover skirt, and vaporization cooling flue 2 is connected to evaporative cooler 3 , the evaporative cooler 3 is sequentially connected to the multi-tube explosion-proof flame arrester 4, the pulse bag filter 5, the smoke plume elimination device 6, the fan 7, the switching station 8 and the chimney 9 through the flue gas pipeline, and the switching station 8 is also connected to the gas cabinet ;

[0042] The tail end of the evaporative cooler 3 is connected to a compressed nitrogen gas source through a compressed nitrogen heating device 19;

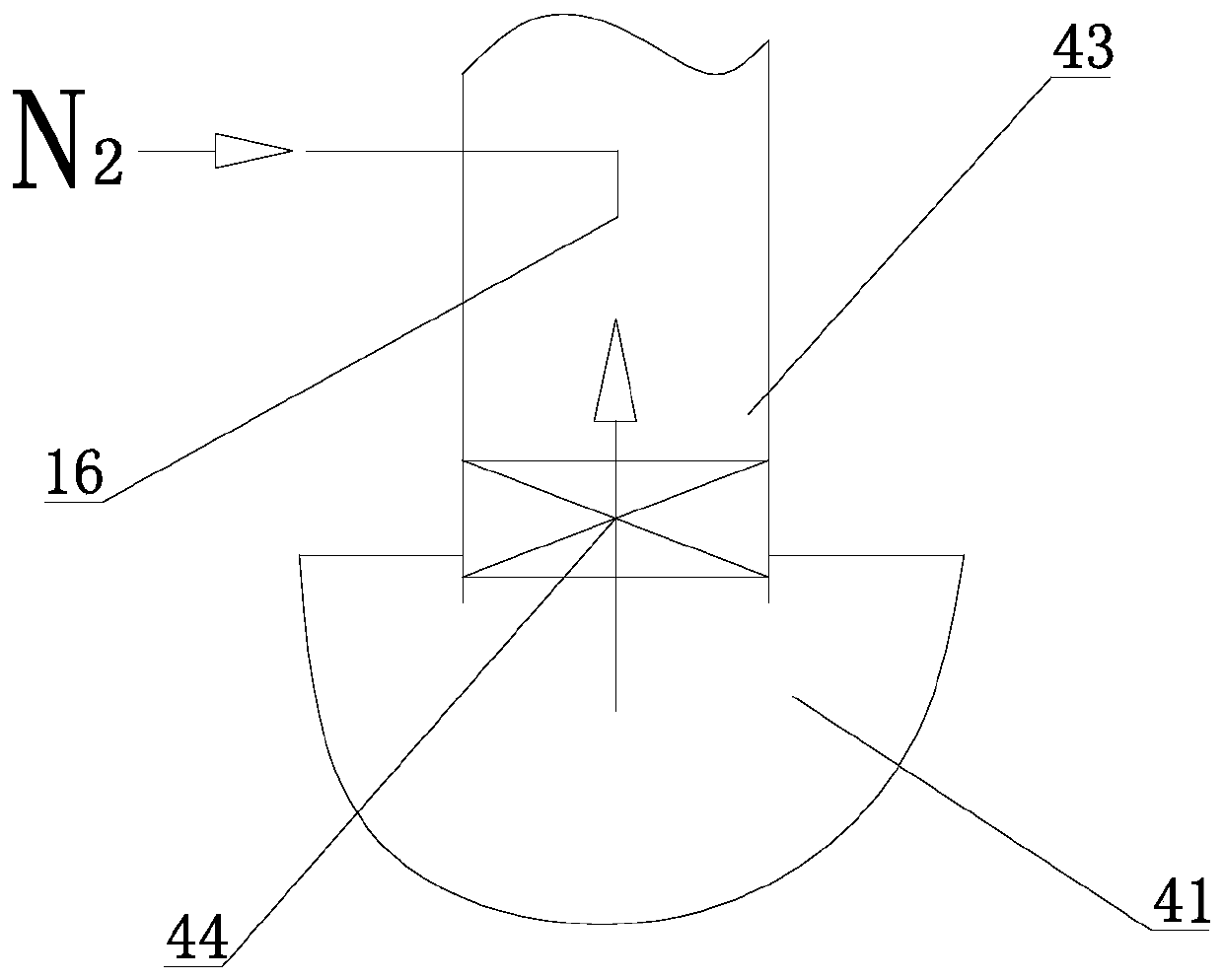

[0043] The multi-pipe anti-flammability flame arrester 4 includes a smoke inlet chamber 41 and a smoke exhaust chamber 42, and a plurality of thin smoke exhaust pipes 43 made of steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com