Sleeve type gas combustor with electronic ignition device

An electronic ignition and sleeve-type technology, which is applied in the direction of burners, gas fuel burners, and combustion methods, can solve problems such as explosions, safety hazards, and easy combustion of gas, and achieves convenient installation, safe combustion, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

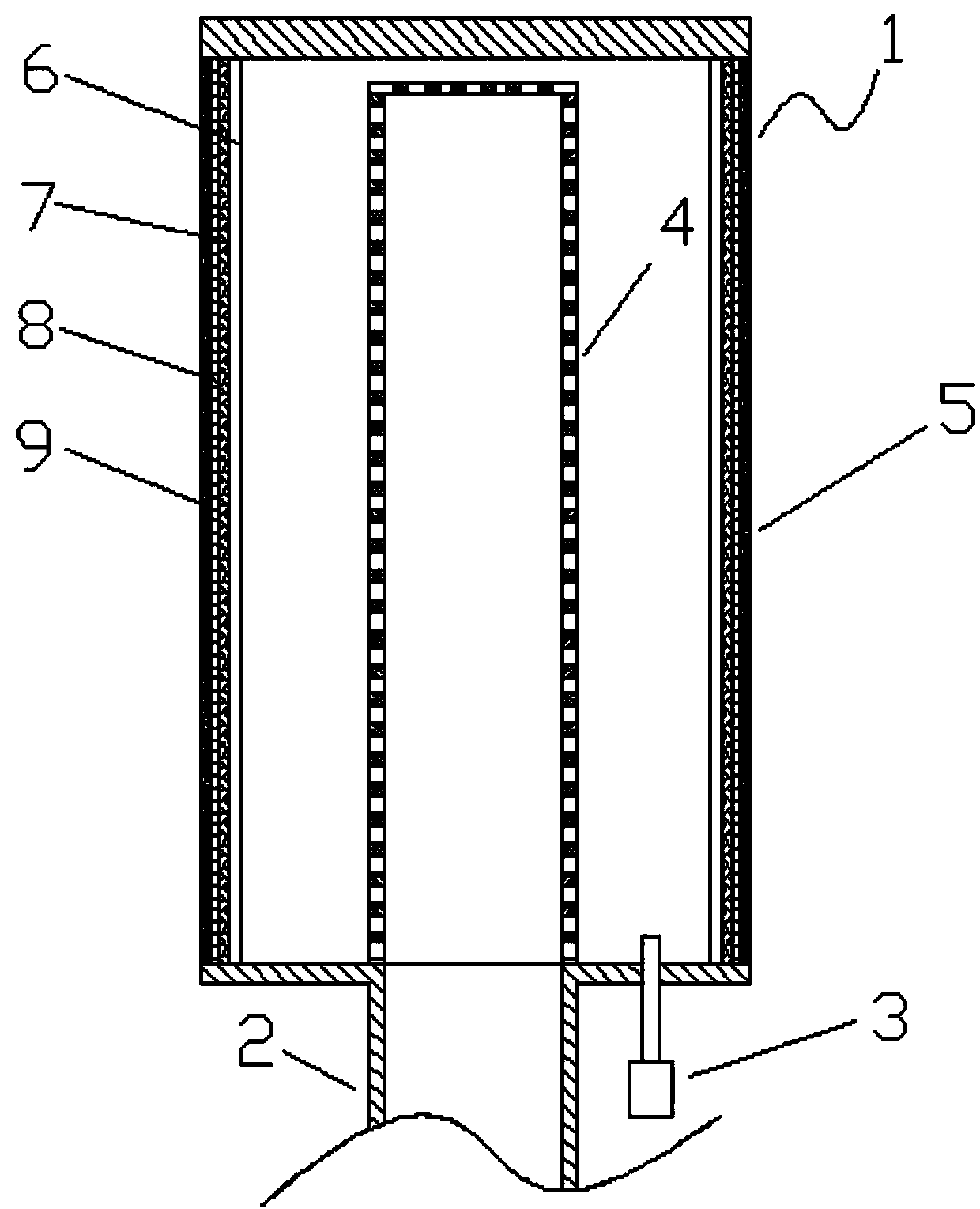

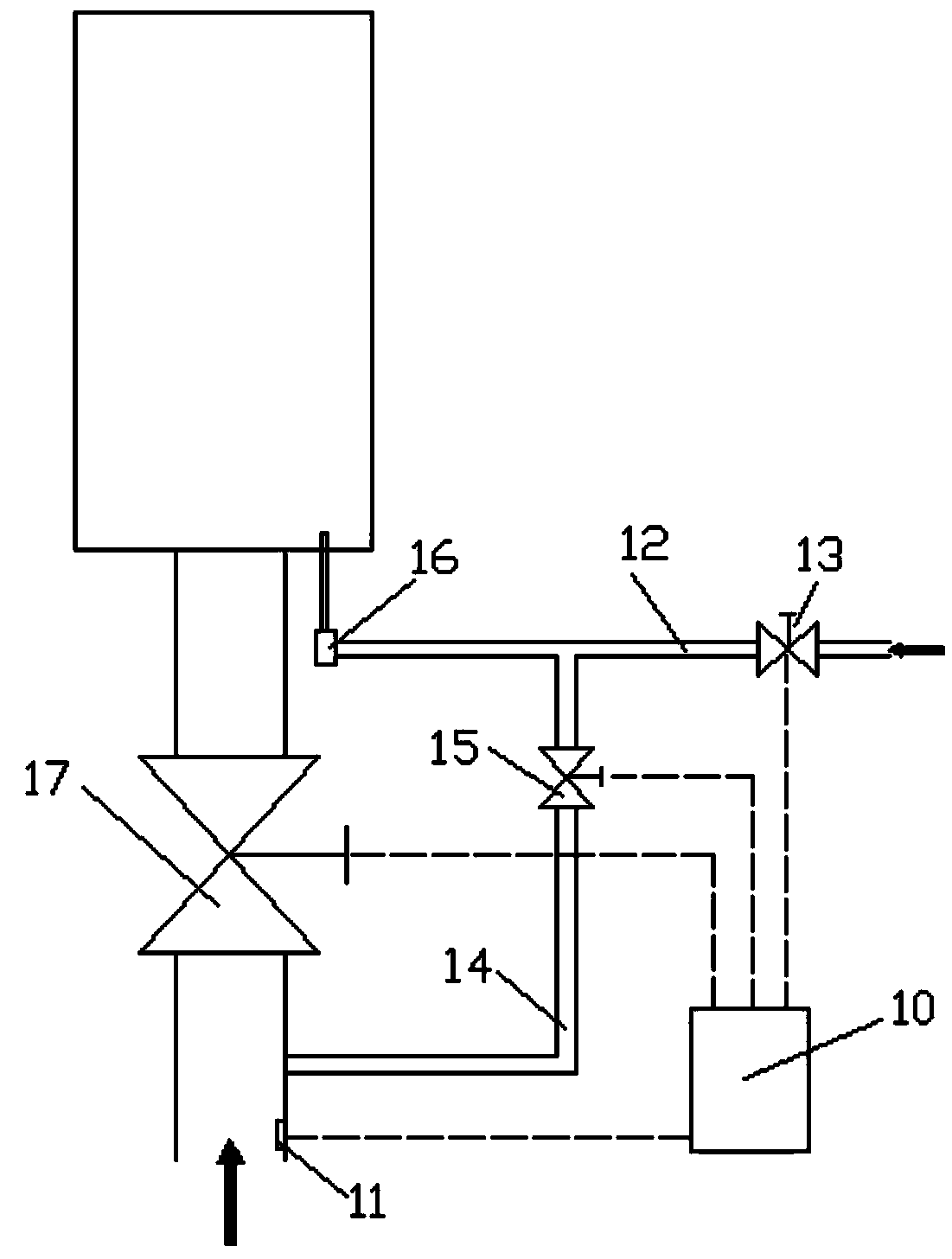

[0024] As shown in the figure, the sleeve type gas burner using electronic ignition device of the present invention includes a combustion chamber 1, a gas input pipe 2 and an electronic ignition device 3, the combustion chamber 1 includes an inner cylinder 4 and an outer cylinder 5, and the inner cylinder The bottom of the body 4 communicates with the gas input channel 2, and the outer cylinder 5 is coaxially installed outside the inner cylinder 4 and wraps the inner cylinder inside, forming a combustion transition chamber between the two; in this embodiment , the shape of the inner cylinder and the outer cylinder of the combustion cylinder are both cylindrical.

[0025] The inner cylinder 4 is made of high-temperature-resistant metal material, and there are a plurality of uniform and finely distributed escape holes on the cylinder body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com