Friction torque testing device for rolling bearing at low temperature

A rolling bearing and friction torque technology, which is applied in the field of friction torque testing devices, can solve the problems of high cost, damage to test instruments, complex structure, etc., and achieve the effects of simple structure, low manufacturing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

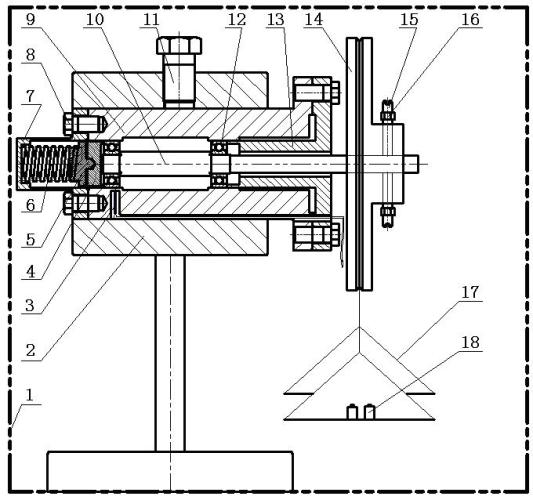

[0023] ginseng figure 1 , the friction torque testing device for rolling bearings at low temperature comprises a support (2) and a pair of tested rolling bearings (12) of the same type, characterized in that the pair of tested rolling bearings (12) of the same type are installed on a shaft The two ends of (10) are put into a sleeve (9), and the two ends are respectively fixed on the described support (2) with the left end cover (7) and the right end cover (13), and the sleeve (9) ) is drilled near the rolling bearing (12) to be tested and placed into a temperature sensor (3) to measure the temperature change of the bearing, and the protruding end of the shaft (10) is fixed with two set screws (15) to a balance wheel ( 14), the two ends of the set screw (15) are equipped with two balance nuts (16) to fine-tune the eccentricity of the balance wheel (14), a thin rope goes around the balance wheel (14) and a pallet is suspended at both ends ( 17), when the weight (18) is put into...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, and the more specific detailed structure is as follows:

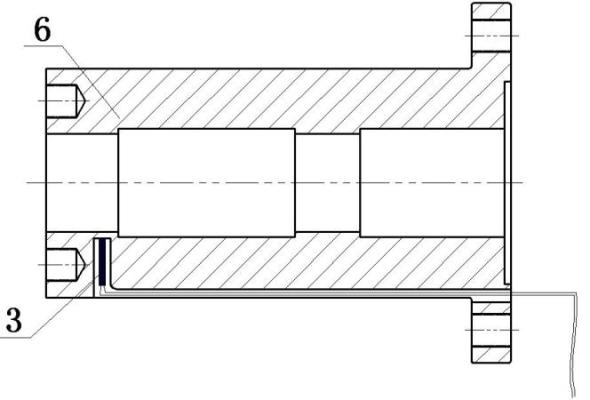

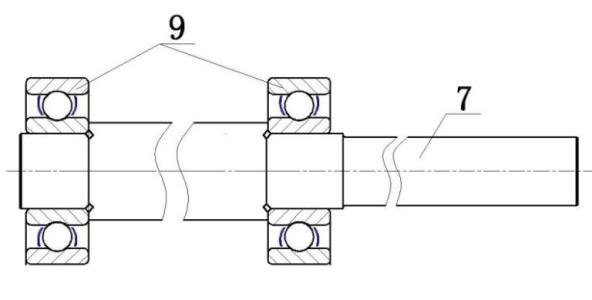

[0026] This example is: see figure 1 , the friction torque test device for rolling bearings under low temperature, including the cold control box (1) for controlling the ambient temperature, see figure 2 , The sleeve is drilled to be close to the bearing, and the temperature sensor PT100 (3) is pasted in the hole, and the lead wire is connected to a digital display to display the temperature change. see image 3 A pair of test rolling bearings (12) of the same type are installed on both ends of the shaft (10) with prepared special tooling, the shaft (10) is closely matched with the test bearing (12), the shaft shoulder is positioned for the bearing, and the height of the shaft shoulder is low The rib size of the inner ring of the bearing.

[0027] The above-mentioned device is put into the sleeve (9), and the outer ring of the test bearing (12) is loosely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com