Rolling friction piston pressure gauge

A technology of piston pressure gauge and rolling friction, which is applied to the measurement of fluid pressure, calibration/testing of force/torque/power measuring instruments, instruments, etc., which can solve the problems of difficult control, time-consuming and laborious, etc. Ease of operation and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

[0047] 1. Structural composition of rolling friction piston pressure gauge

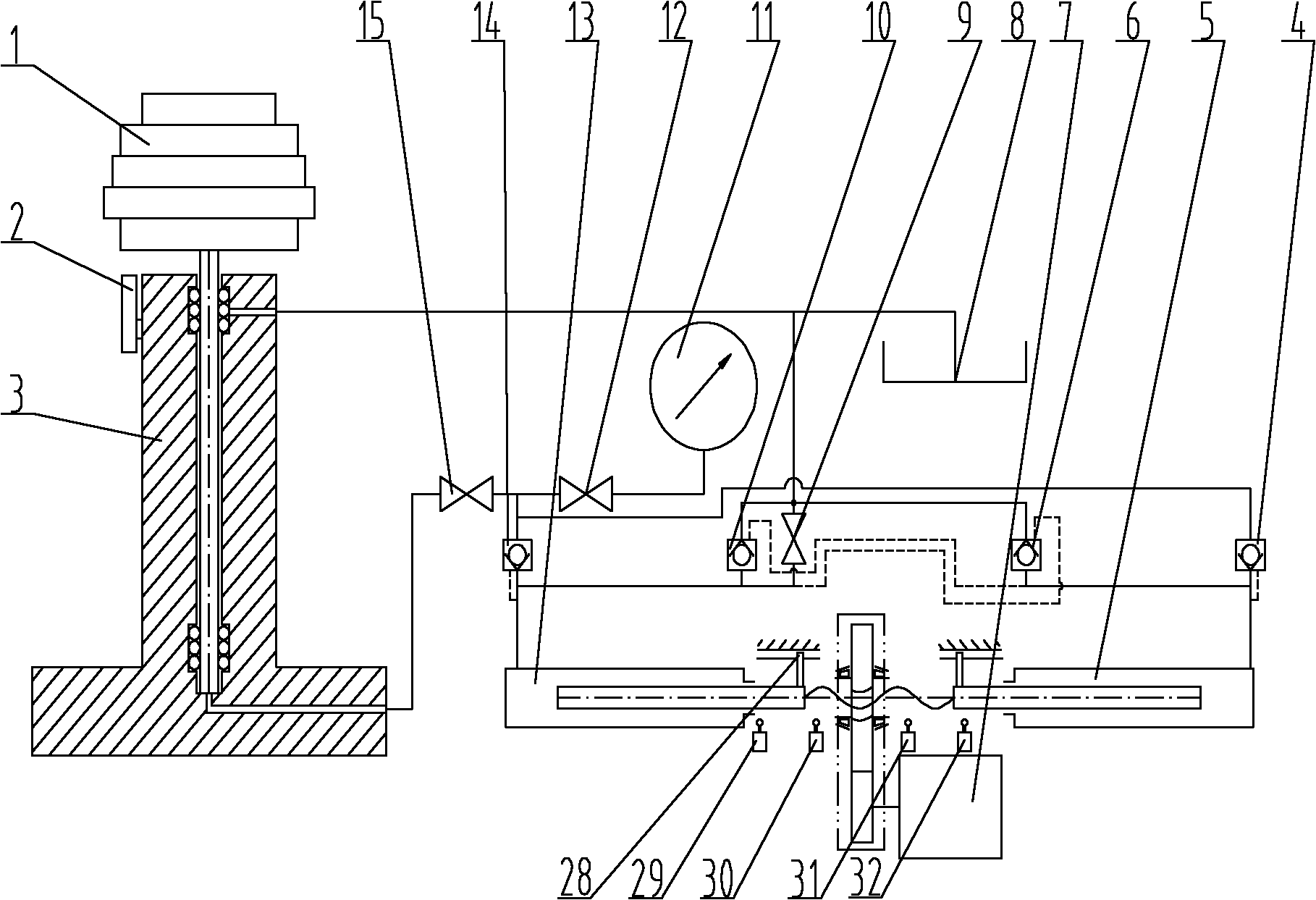

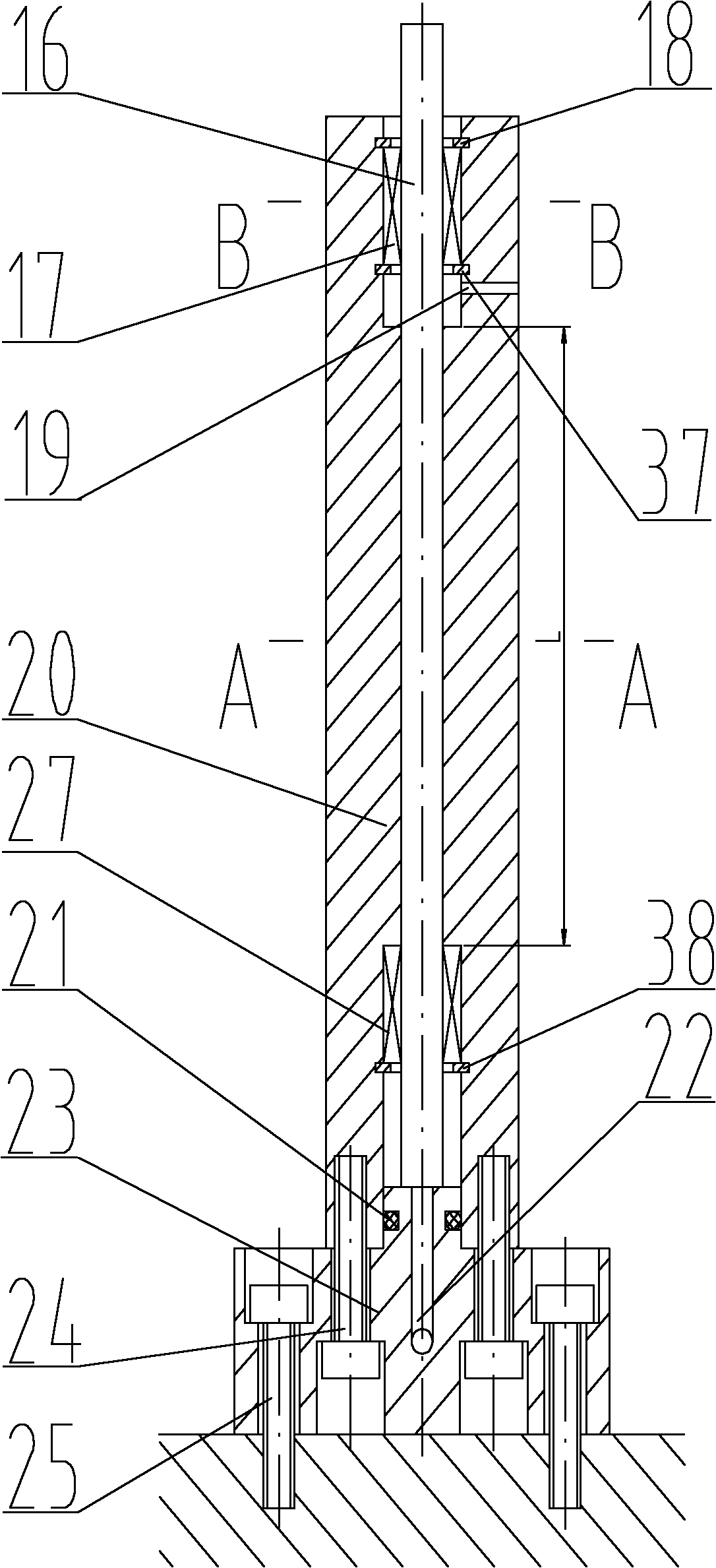

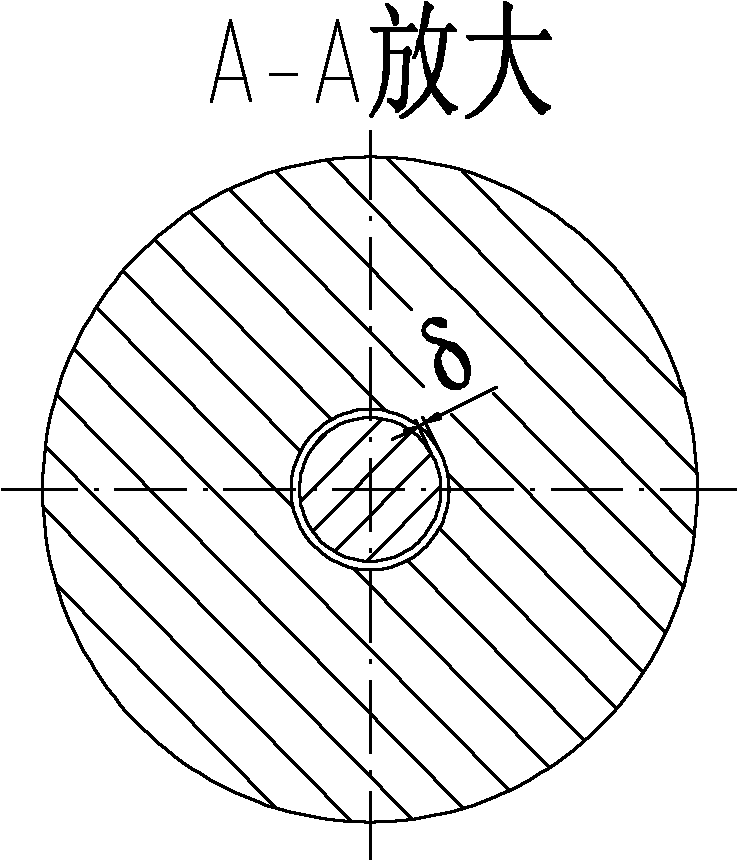

[0048] refer to figure 1 and Figure 13 , the rolling friction piston pressure gauge includes a rolling friction piston cylinder 3, a calibrator, a special weight 1, an electronic control system and a pressure gauge casing 35. The special weight 1 can directly act on the top of the piston, or add it to the reverse frame 33 through the weight loading and unloading drive mechanism 34 fixed on the inner wall of the pressure gauge box, and then act on the rolling friction piston cylinder 3 through the reverse frame The top of the piston in the tester is connected with the oil inlet 22 pipeline through No. 1 shut-off valve 9, No. 3 shut-off valve 15, etc. and the oil drain port 19 on the rolling friction piston cylinder 3. The calibrator is installed in the pressure gauge box, and the rolling friction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com