Remote control controlled area network (CAN) bus testing device and method

A CAN bus and remote control technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as difficult integration, inability to implement applications, inability to integrate the advantages of bus analyzers and bus oscilloscopes, etc., to achieve Save manpower and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

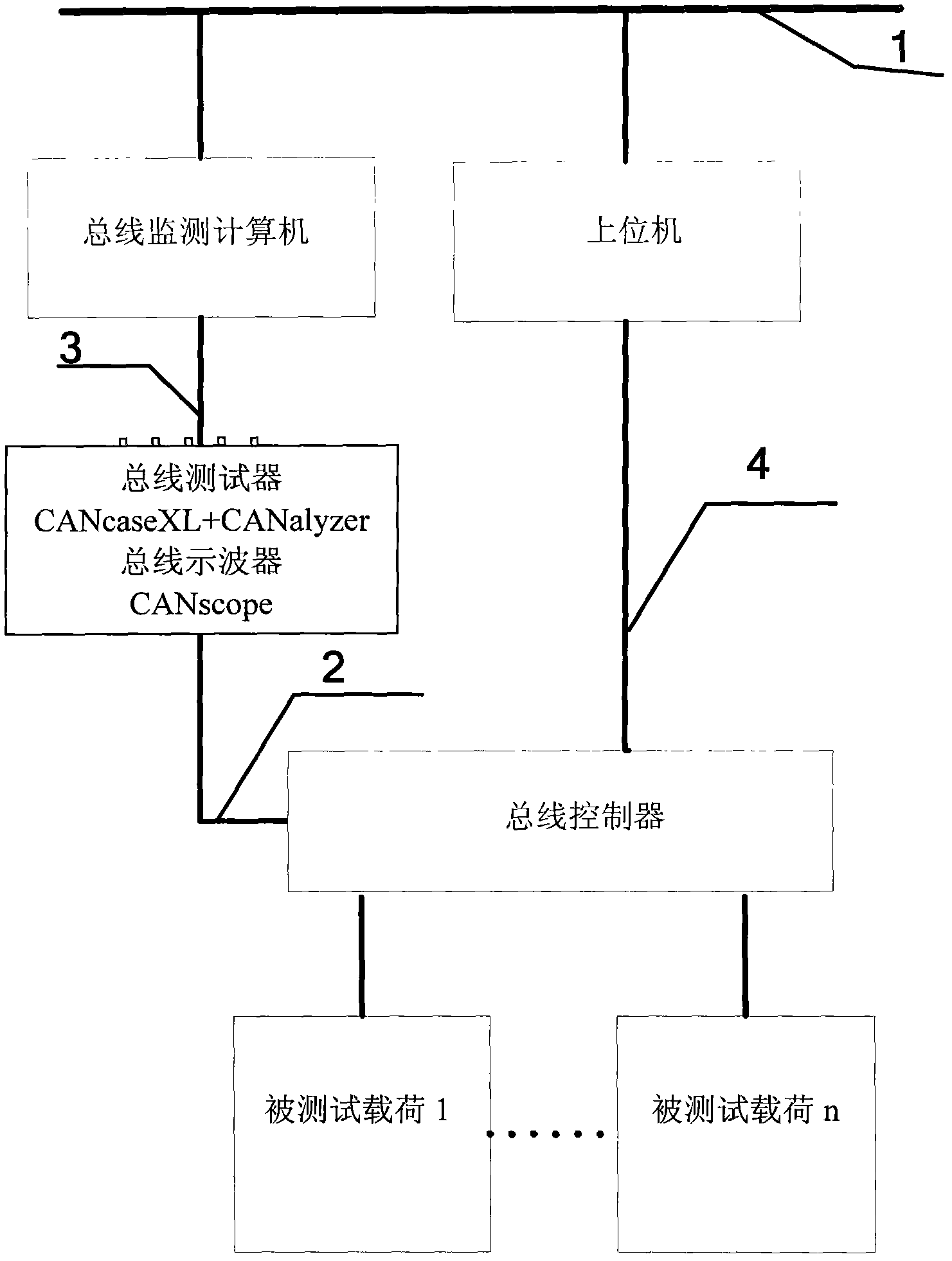

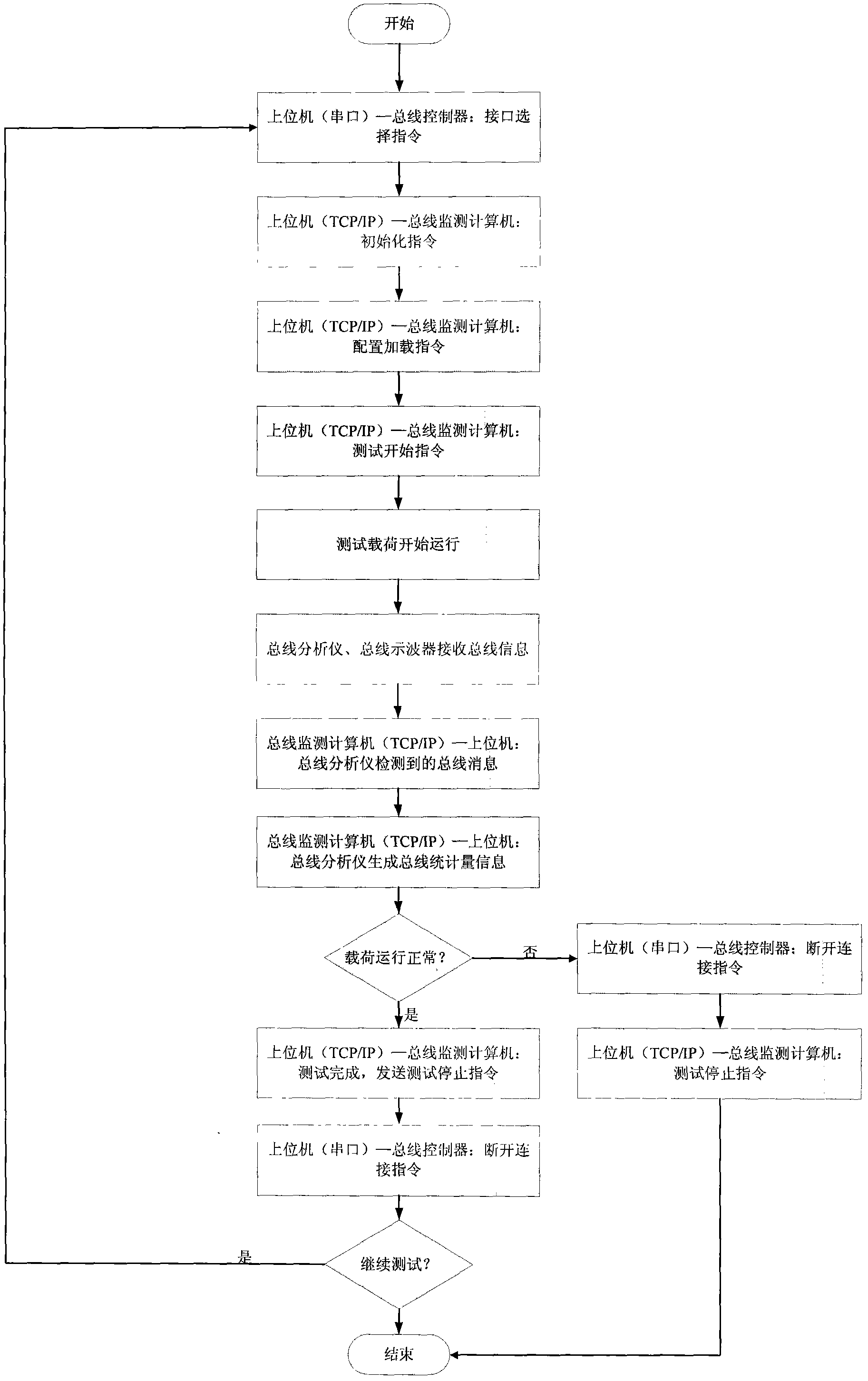

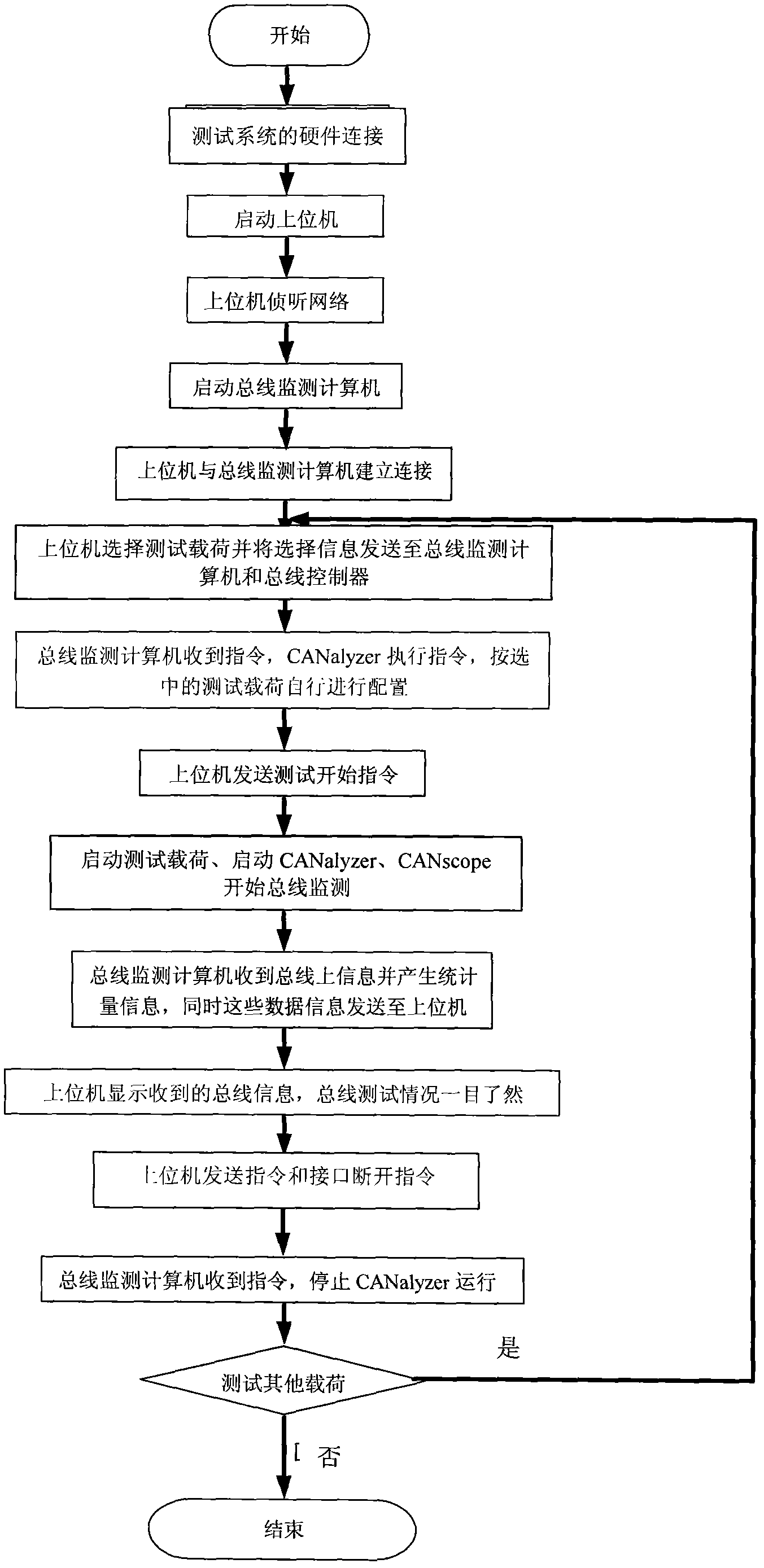

[0039] Device embodiment: refer to figure 1, The device of the present invention includes a host computer, a bus interface controller, a bus monitoring computer, a bus analyzer, a bus oscilloscope, tested loads 1 to n, a CAN bus and an Ethernet network. Connect the CAN bus analyzer and the CAN bus oscilloscope to a computer in the test system as a bus monitoring computer, and the bus monitoring computer is connected to the main control computer (host computer) in the test system through Ethernet. Use TCP / IP protocol for data transmission. Connect the CAN bus analyzer, CAN bus oscilloscope and the load to be tested to the CAN bus interface controller, thus forming a scalable CAN bus test network. It can be expanded according to the different requirements of the test system according to the load, so as to meet the test requirements. According to the test requirements, the host computer sends an interface selection command to the CAN bus interface controller, so that the CAN bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com