Profile for forming solar photovoltaic component border

A solar photovoltaic and profile technology, which is applied in the field of profiles constituting the frame of solar photovoltaic modules, can solve the problems such as the inability to dissipate heat from the back of solar cell modules smoothly, the reduction of photoelectric conversion efficiency of photovoltaic modules and photovoltaic power generation systems, and the reduction of photoelectric conversion efficiency, etc. To ensure the effect of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

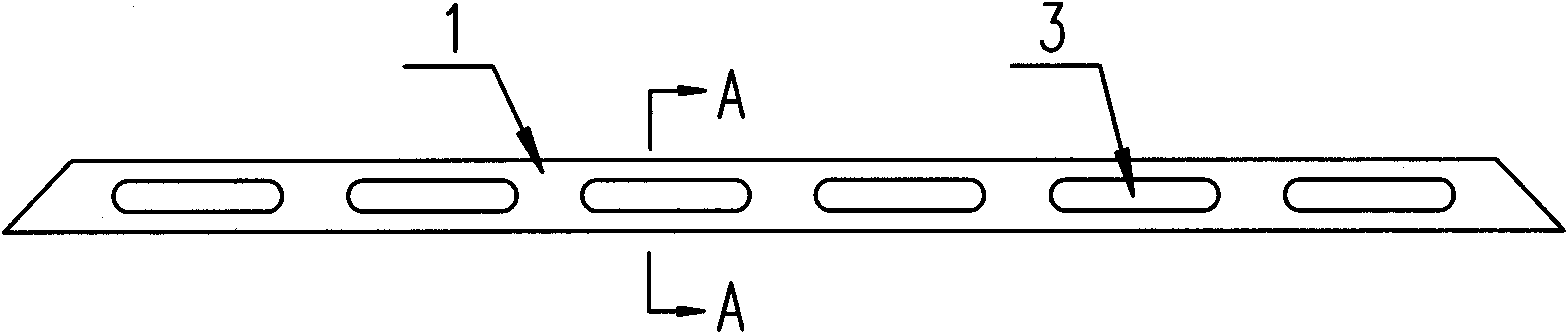

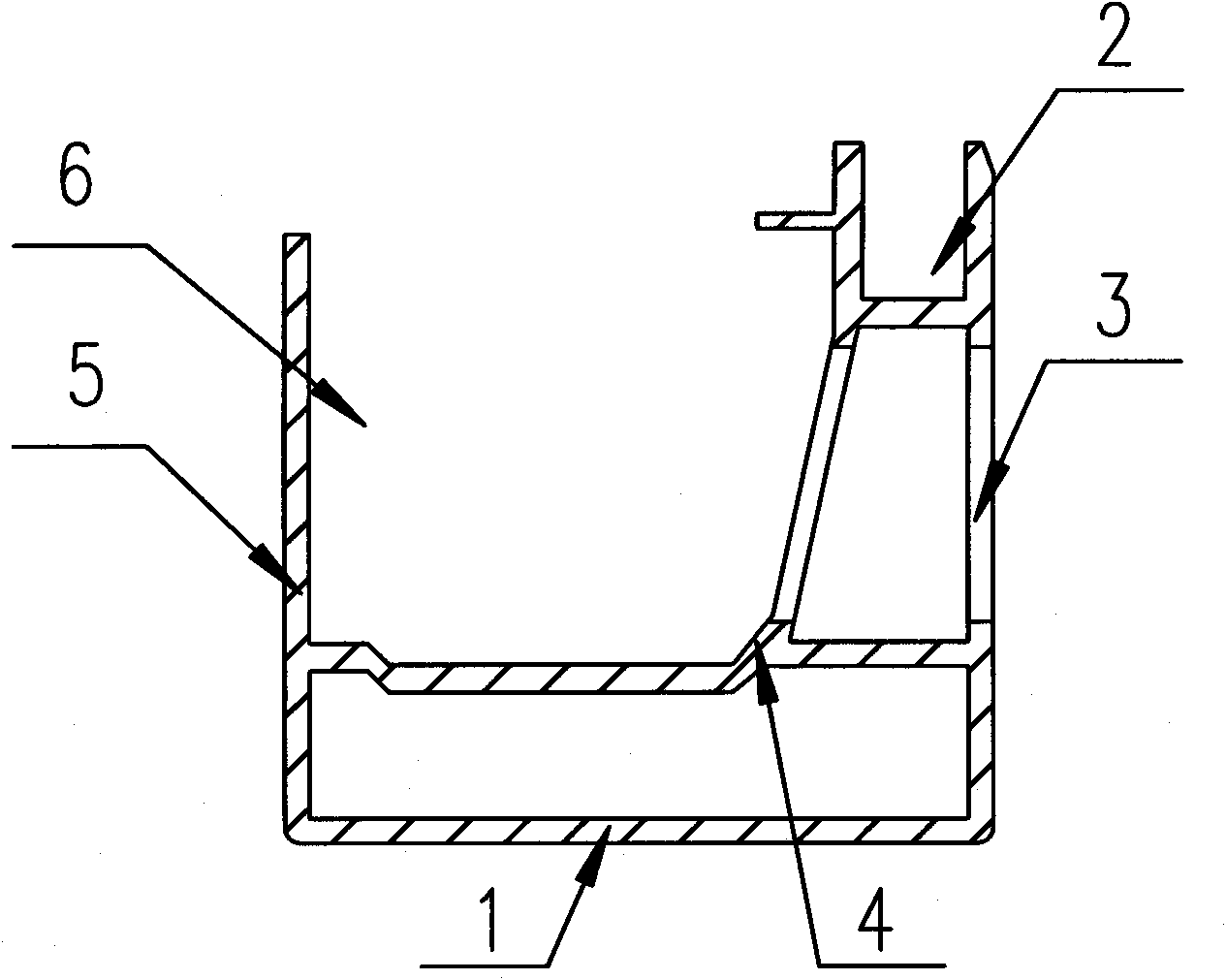

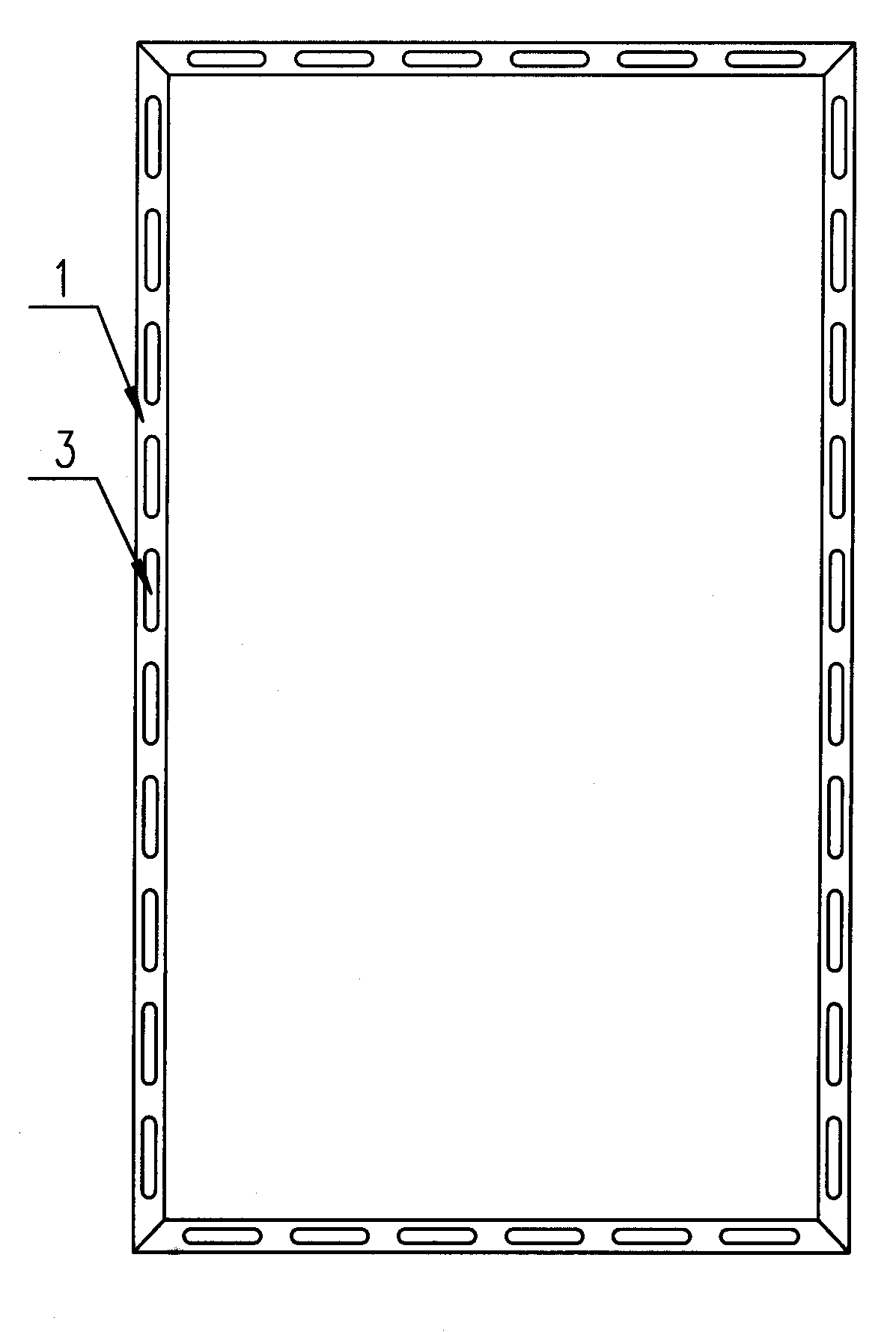

[0013] see figure 1 , figure 2 As shown, the profile used to form the frame of the solar photovoltaic module described in the present invention, the inside of the profile 1 is provided with a bayonet 2 for installing the solar cell module, the profile 1 is provided with a rib 4, and the back surface of the profile It is the installation surface 5, and there is an installation cavity 6 between the installation surface 5 and the bayonet socket 2. Several air holes 3 are evenly arranged on the sunny surface of the profile 1, and the air holes 3 penetrate the reinforcing rib 4 and the The installation cavity 6 is connected. Such as image 3 As shown, four profiles are fixedly connected to each other to form the frame of the solar photovoltaic module.

[0014] When the frame of the solar photovoltaic module composed of the profiles described in the present invention is in use, the heat on the back of the solar cell module can be smoothly discharged through the vent holes, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com