Rapid conductor locking structure

A locking structure and fast technology, applied in the direction of clamping/spring connection, coupling device, contact part, etc., can solve the problems of changing the structure size of metal terminals, prone to false welding, small use range, etc., to achieve great flexibility and extensiveness, improve current carrying capacity, and increase the effect of wire contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

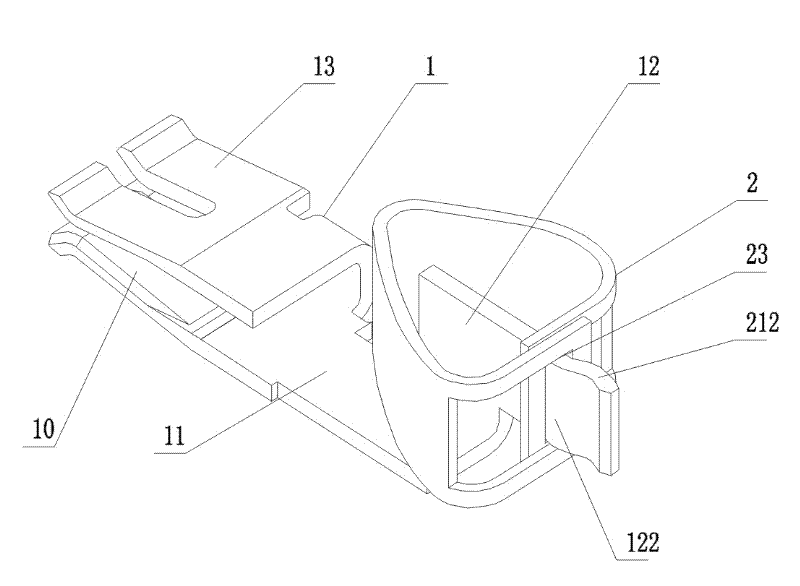

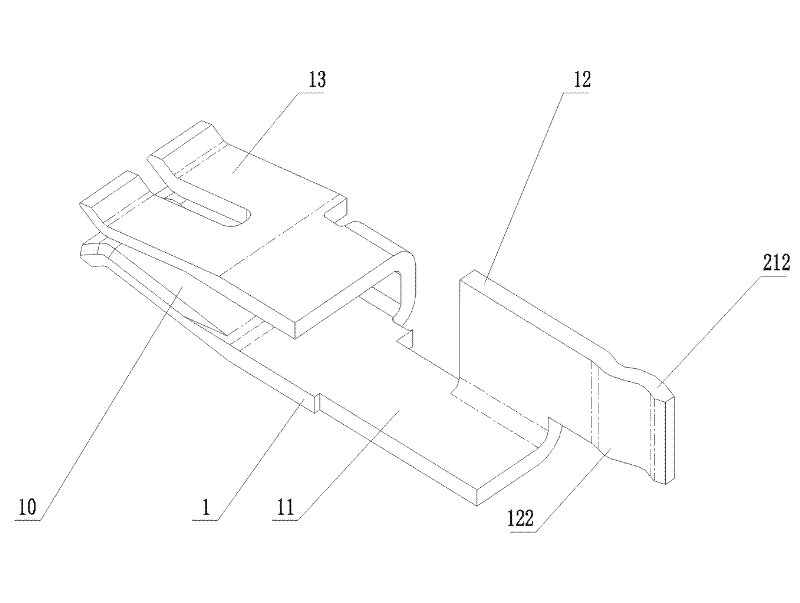

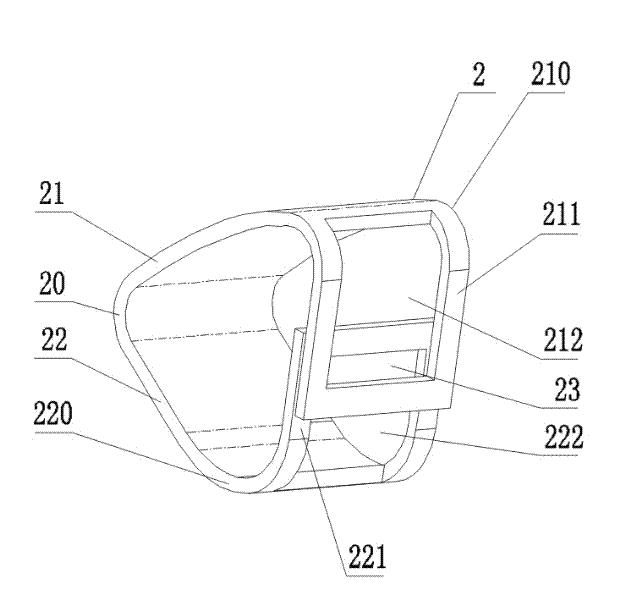

[0011] See attached figure 1 , the present invention includes a metal terminal 1 and a locking coil 2, the metal terminal 1 is formed by connecting the front and rear ends of a lead plate 11 to a butt joint 10 and a crimping plate 12, and the butt joint 10 is two contact pieces 13 connected in parallel; The plate 12 is a pressing plate provided with a front convex hull 121 and a rear convex hull 122, and the pressing plate 12 is connected at right angles to the lead plate 11; The circlip connected by a triangle, the upper cantilever beam 21 is provided with a downwardly bent A lockline window 212, and the lower cantilever beam 22 is provided with an upwardly bent B lockline window 222, and the A lockline window 212 and the B lockline The thread window 222 overlaps to form a slit-shaped thread-locking opening 23, the thread-pressing plate 12 is sleeved with the thread-locking coil 2, and the rear convex hull 122 protrudes from the thread-locking port 23, and the thread-pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com