Convenient multifunctional food processing machine and quick pulping method thereof

A multi-functional food and processing machine technology, applied in home appliances, applications, kitchen utensils, etc., can solve problems such as single function, difficult to adapt to fast-paced life, and inability to make pulp, so as to achieve the effect of quick and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

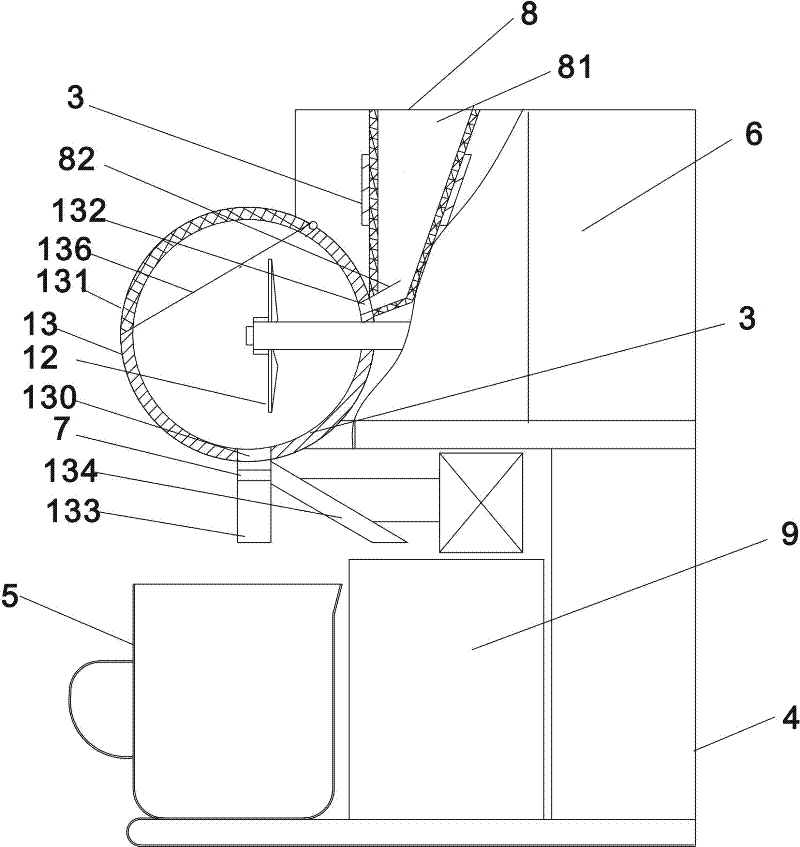

[0035] As an embodiment of the portable multifunctional food processor of the present invention, such as figure 1 As shown, it includes a machine body 4, a feeding unit, a heating unit, a control unit, a slurry unit and a crushing unit, the control unit (not shown in the figure) is arranged in the machine body 4, and the crushing unit is connected to the feeding unit Generally speaking, the crushing unit and the feeding unit are all arranged on the machine body 4, the control unit is electrically connected to the crushing unit, the slurry holding unit is arranged downstream of the crushing unit, and the crushing unit includes a motor (not shown in the figure) out), an airtight or nearly airtight small space pulverizer 13 and a pulverizer 12 arranged in the small space pulverizer 13, the volume of the small space pulverizer 13 is 56 to 799 milliliters, and the motor responds to the signal sent by the control unit The command drives the pulverizing cutter 12 to pulverize, stir a...

Embodiment approach 2

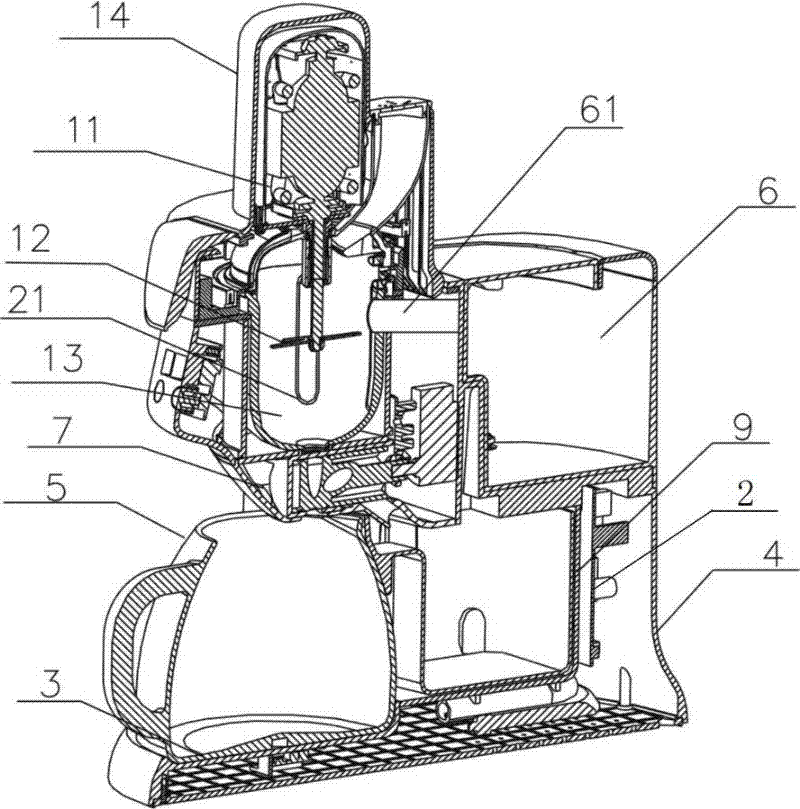

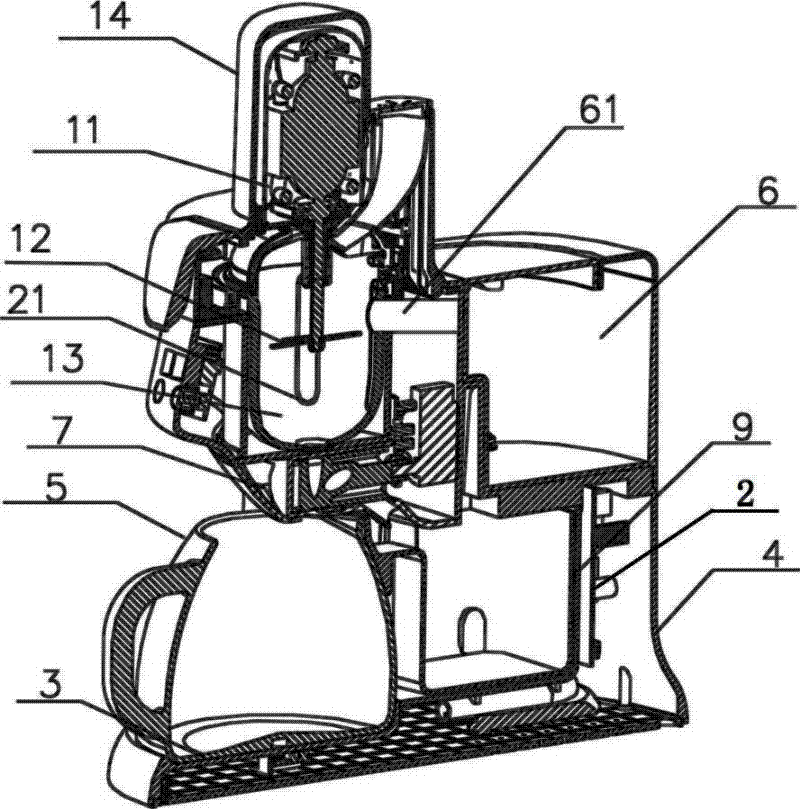

[0067] As embodiment two of the portable multifunctional food processing machine of the present invention, as figure 2 As shown, the difference from Embodiment 1 is that the control unit 2 is arranged below the body, and heating devices are provided on the water tank 6 and the pulp holding device 5, and the heating unit on the pulp holding device 5 is arranged at the bottom thereof The heating device 3 is an electric heating plate, and the water tank 6 communicates with the small space pulverizer 13 through the water inlet channel 6 . The small space pulverizer 13 is a cylinder, the motor 11 is arranged in the motor chamber 14 above the small space pulverizer 13, and the motor 11 drives the pulverizer 12 to rotate through a shaft coupling. The remaining structures and beneficial effects of this embodiment are consistent with those of Embodiment 1, and will not be repeated here.

[0068] The method for making the puree by the convenient multifunctional food processing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com