Mop twisting machine

A water machine and mop technology, which is applied in the field of mop cleaning equipment and mop twisting machines, can solve the problem that the mop cleaning device cannot be well applied to round-headed mops, and achieve a good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

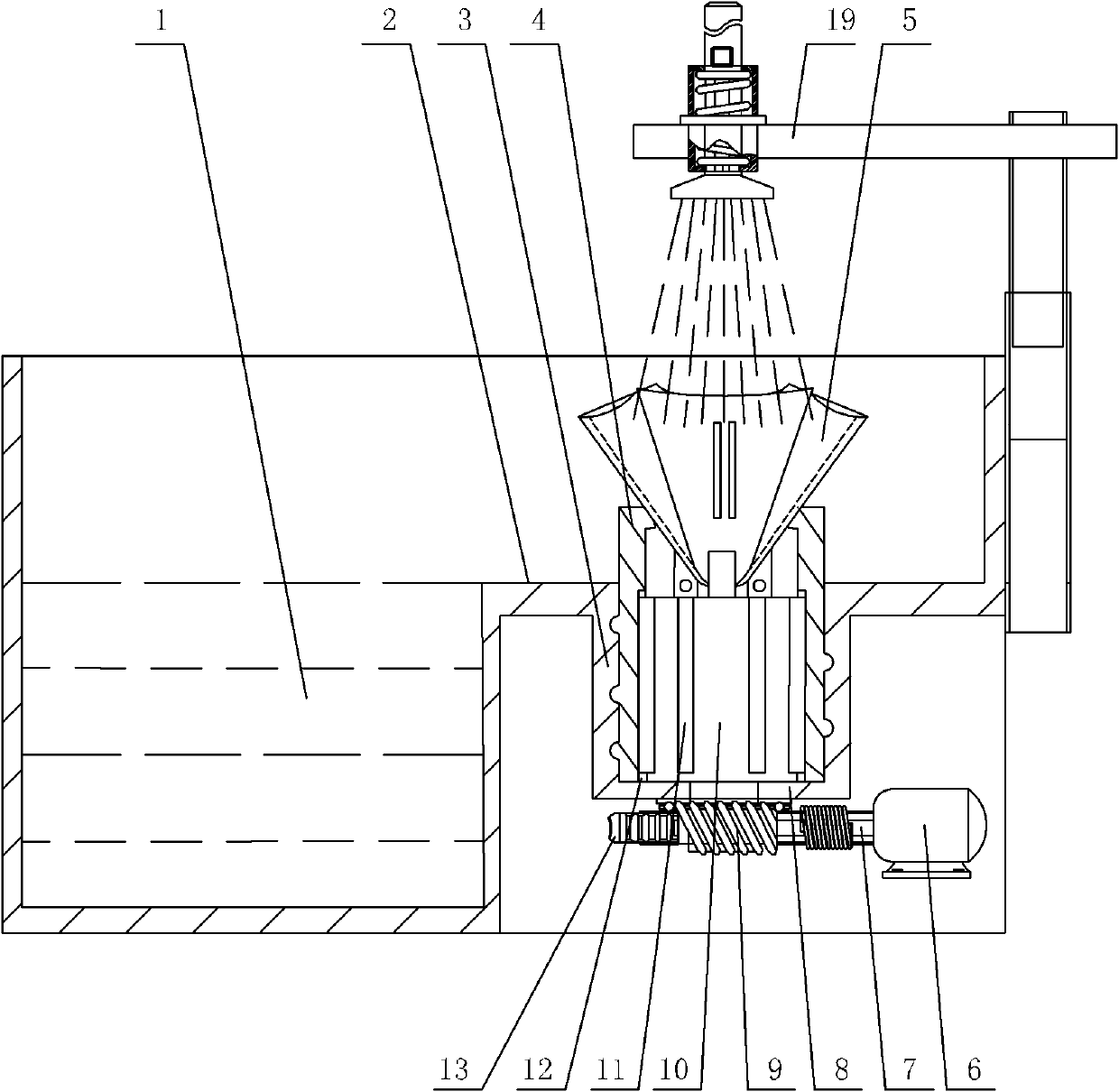

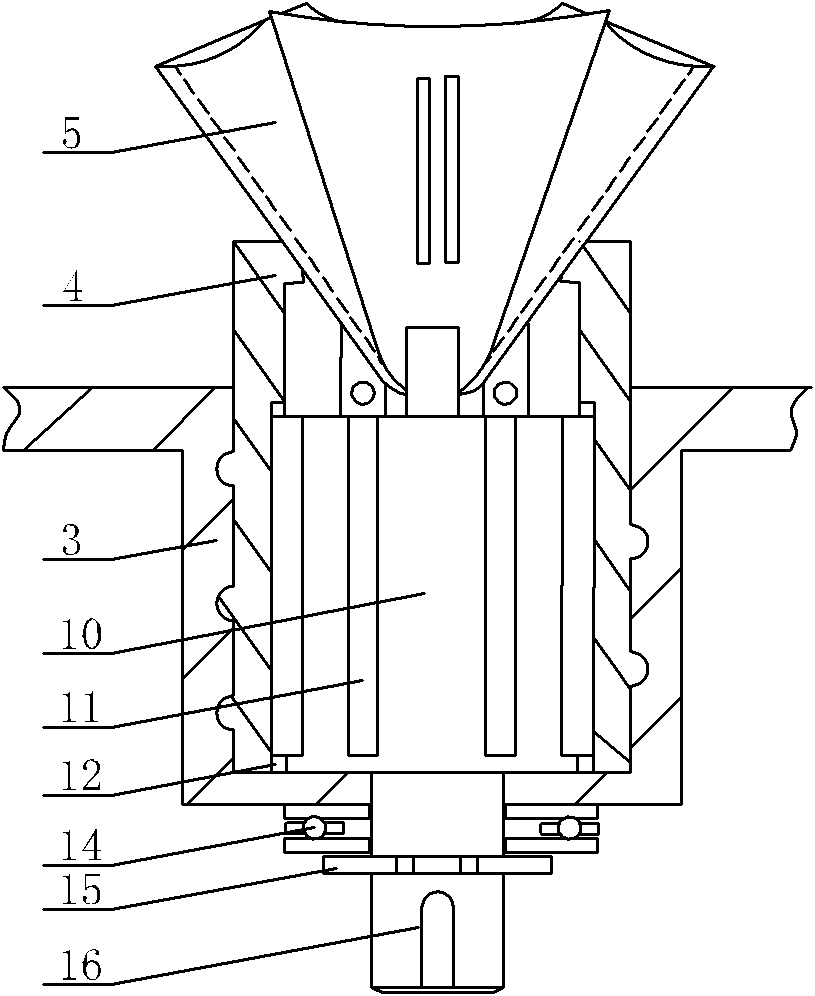

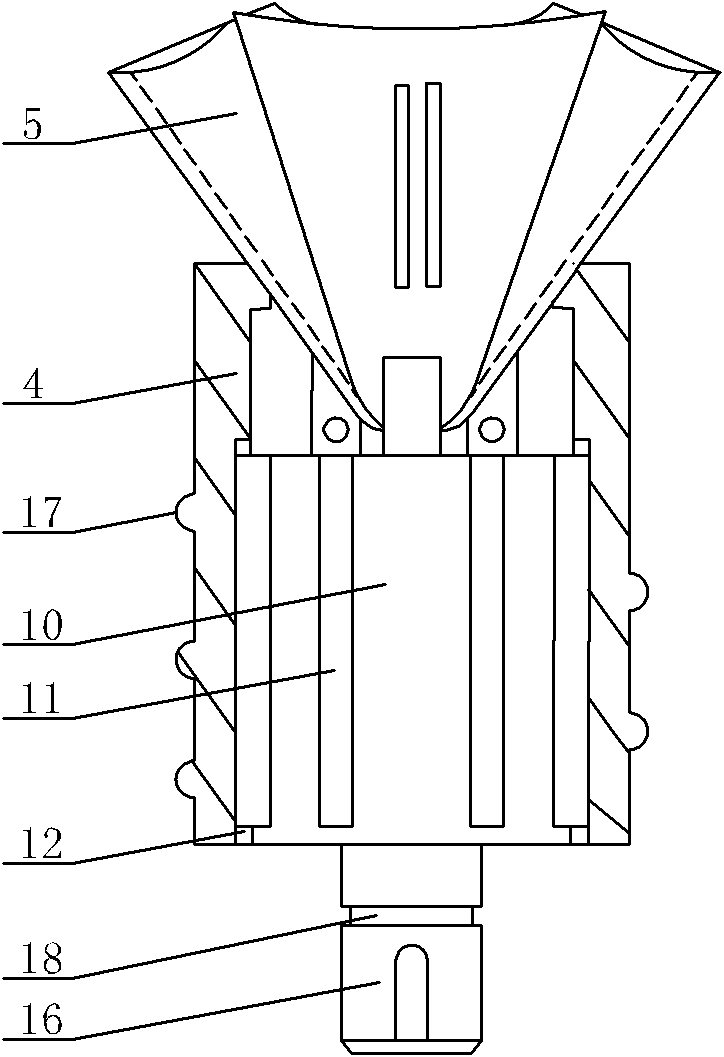

[0066] refer to Figure 1-3 , the figure shows a specific application example of the mop water twister of the present invention. In this example, the mop water twister includes a frame 2, and the left side of the frame 2 is a bucket 1, and the right side is a water bucket 1. A clamping and rotating device installation groove is provided, the side wall 3 of the clamping and rotating device installation groove is provided with a right-handed internal thread, and the bottom 8 is provided with a shaft hole. The clamping and turning device includes a cylindrical main body 10 , six opening and closing plates 5 for clamping the mop cloth, and a control sleeve 4 set on the outside of the main body 10 . The lower end of the cylindrical main body 10 has a short installation shaft 16, the short installation shaft 16 protrudes from the shaft hole at the bottom 8 of the installation groove of the clamping device, and the outer diameter of the short installation shaft 16 is the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com