Ammonia water recovery device

A recovery device and ammonia water technology, which are applied in ammonia preparation/separation, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as unreachable, environmental impact, and environmental pollution, and achieve good absorption and recovery effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

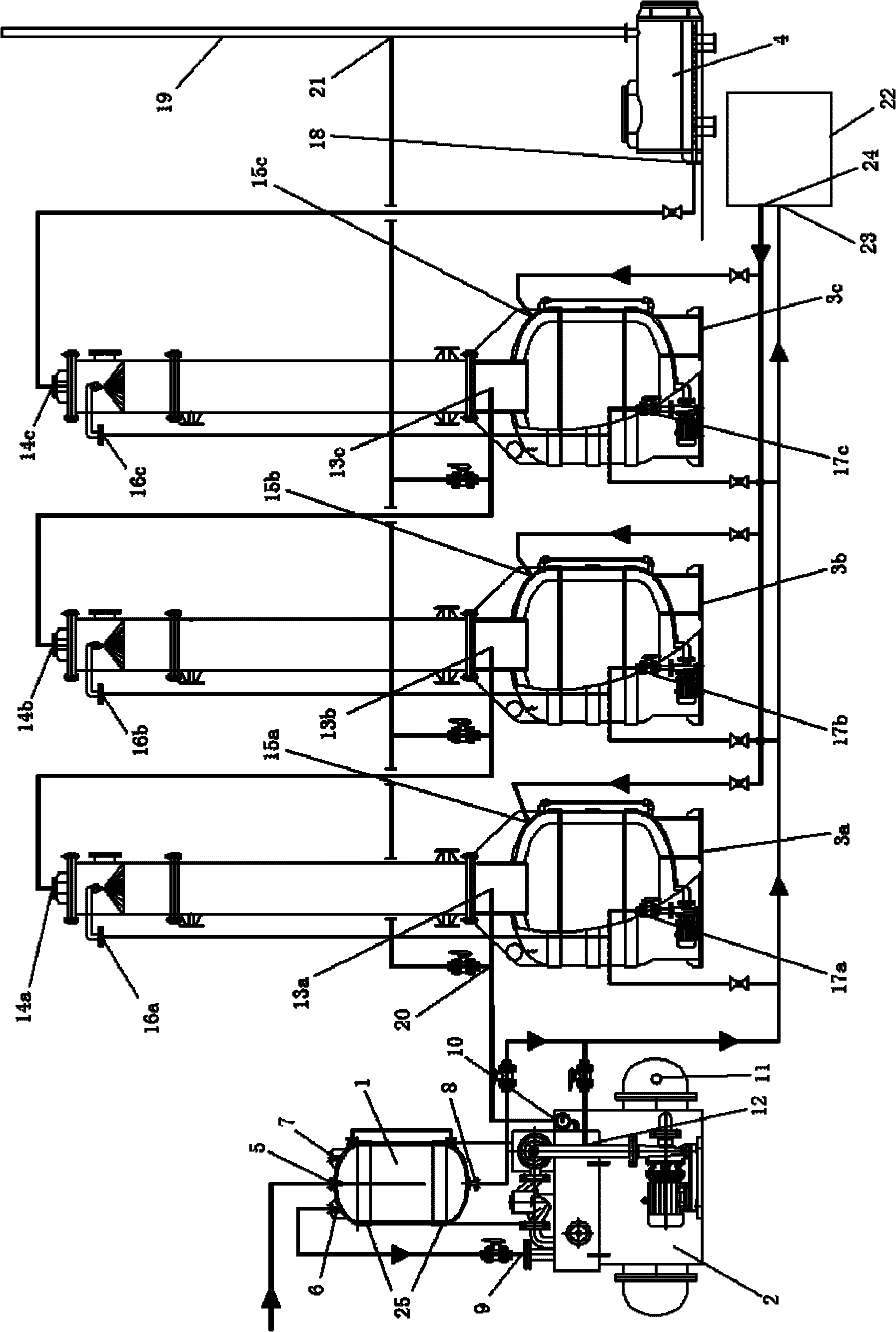

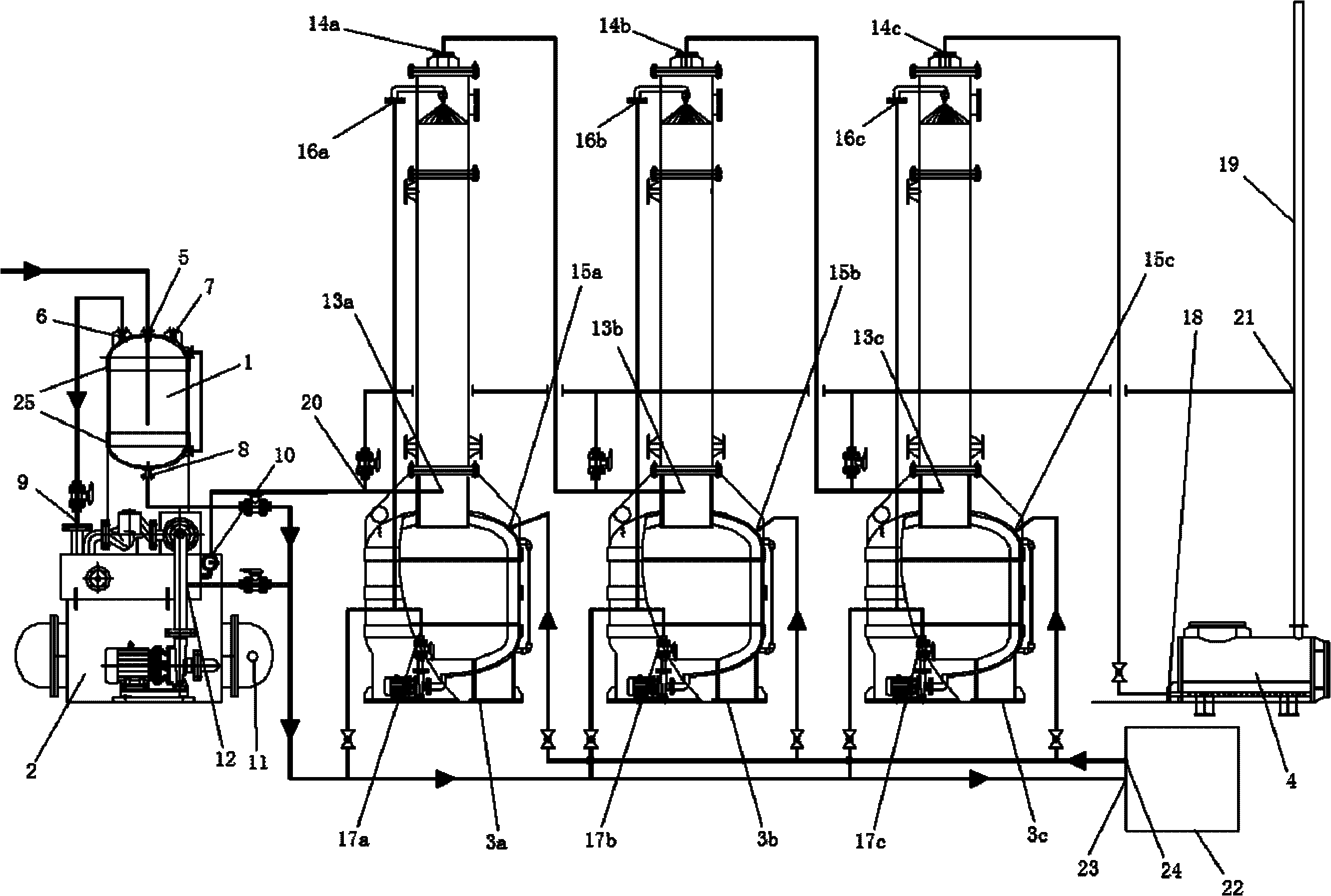

[0012] Such as figure 1 Shown, a kind of ammonia recovery device comprises gas buffer tank 1, the vacuum unit 2 that joins with gas buffer tank, the first absorption tower 3a that joins with vacuum unit 2, the second that joins with first absorption tower 3a Absorption tower 3b, the 3rd absorption tower 3c that joins with the 2nd absorption tower 3b, the activated carbon adsorption tank 4 that joins with the 3rd absorption tower 3c and the reservoir 22; The mouth 5, the first air outlet 6, the first water inlet 7 and the first water outlet 8 are also provided with two rings of reinforce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap