Compensation mechanism for stress deformation of spindle box of machine tool

A stress deformation, machine tool spindle technology, applied in metal processing mechanical parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of the stress deformation of the headstock, which cannot be compensated for the position, and the ram shaft is deformed upwards, and achieves weight The effect of light weight, increased span and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

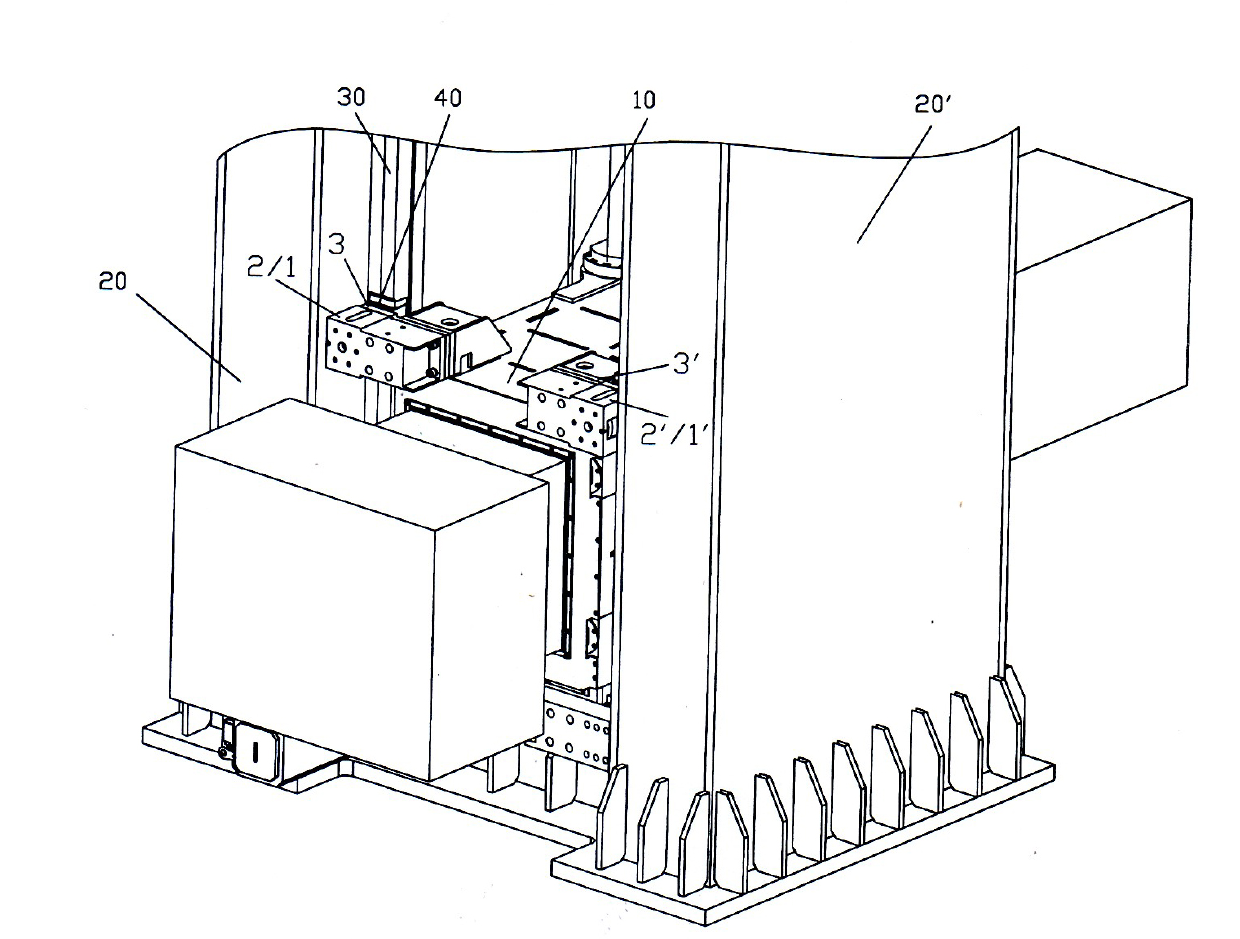

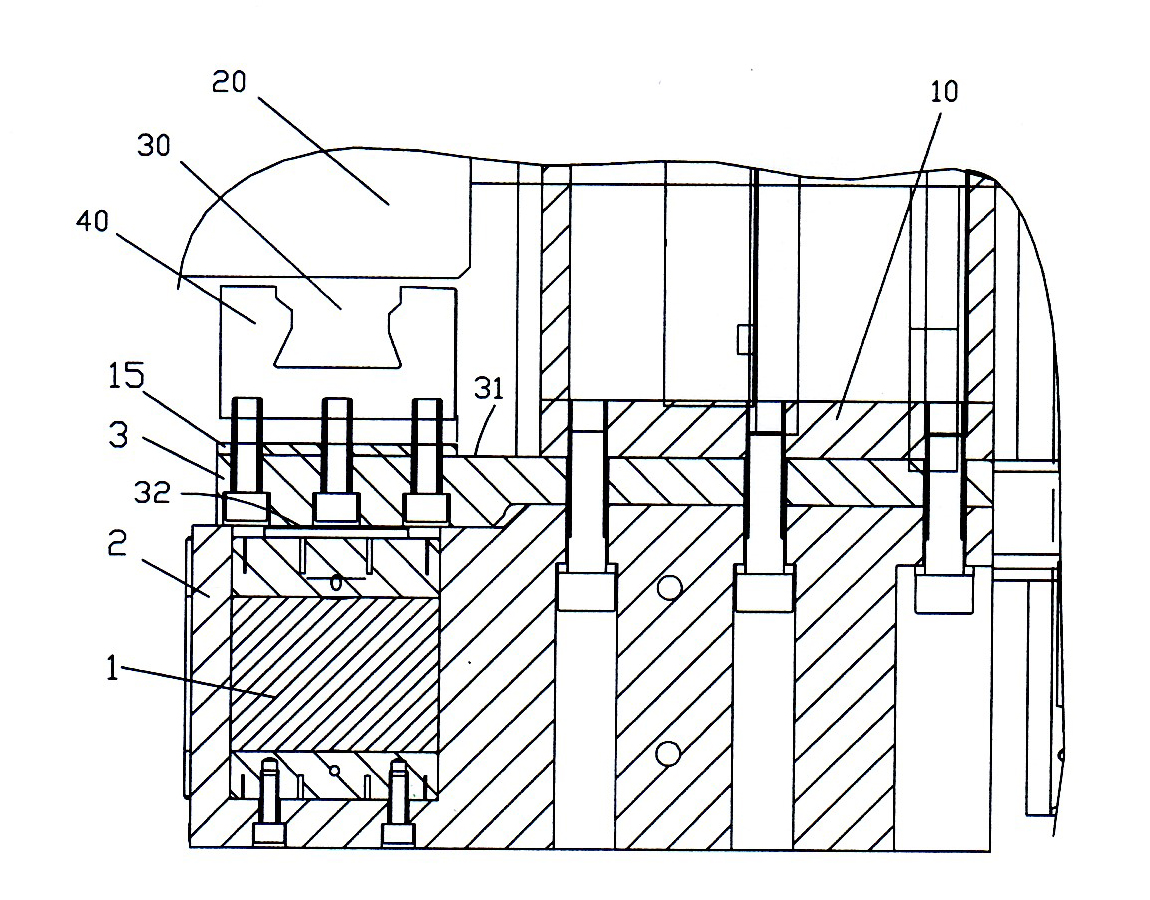

[0028] see Figure 1 ~ Figure 3 , the compensation mechanism for the stress deformation of the spindle box of the machine tool, the spindle box 10 is located between the two columns 20, 20', forming a door-type thermal deformation symmetrical structure, and the front and rear contact surfaces between the spindle box 10 and the two columns 20, 20' are respectively Two guide rails 30 and a slider 40 are provided to form a vertical guide support.

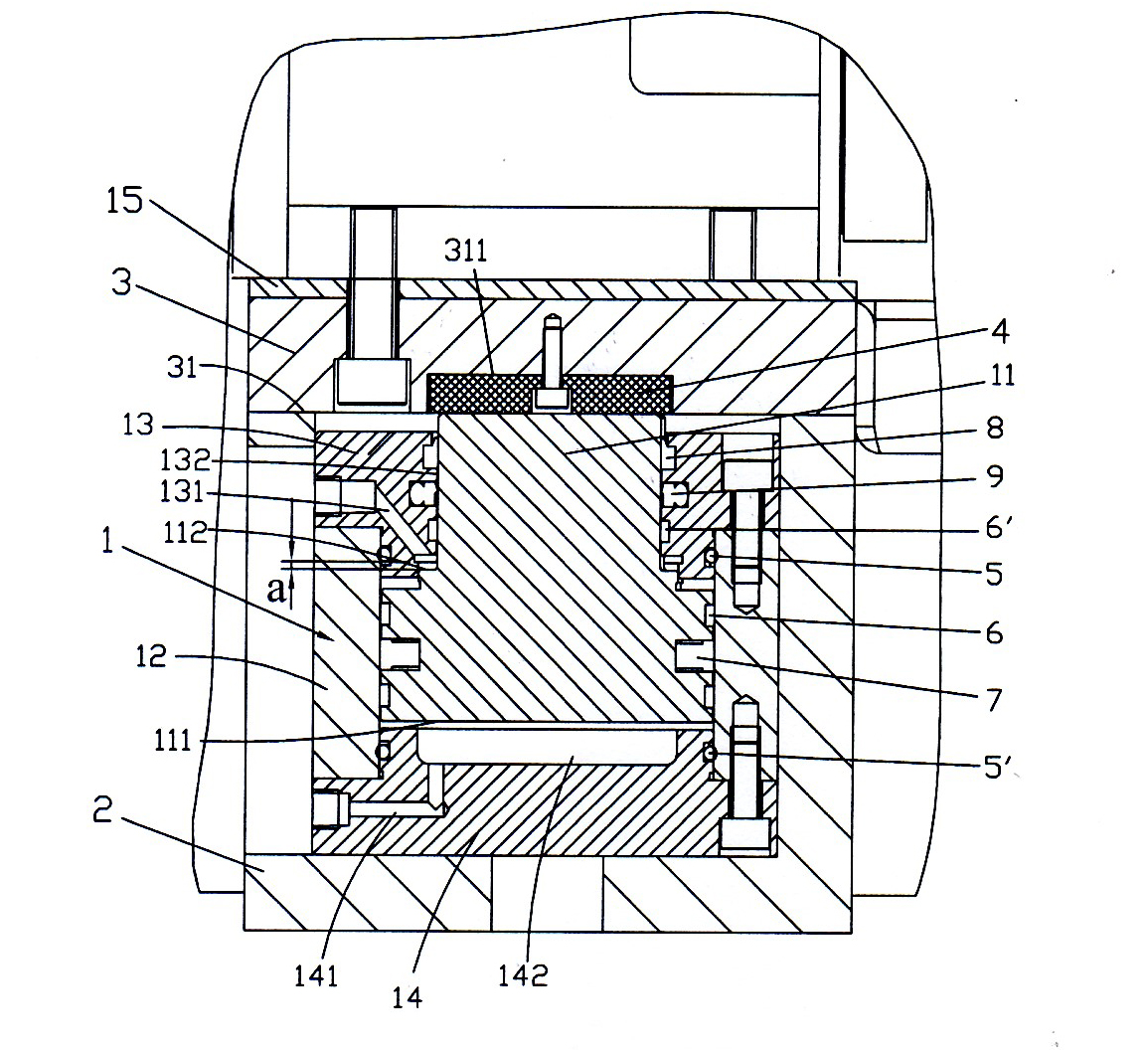

[0029] The compensation mechanism includes two compensation oil cylinders 1, 1', which are respectively arranged in a support shell 2, 2', and the two support shells 2, 2' are symmetrically installed on both sides of the upper end surface of the rear part of the headstock 10 respectively. Two transition connecting plates 3, 3 ', the two ends of a side surface 31 of the transition connecting plate 3 (taking the compensation oil cylinder 1 and the transition connecting plate 3 as an example, the same below) respectively connect the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com