Online camshaft measuring and machining process

A processing technology and camshaft technology, applied in metal processing, metal processing equipment, measuring/indicating equipment, etc., can solve problems such as low processing efficiency, and achieve the effect of improving processing efficiency, ensuring processing accuracy, and avoiding waste products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

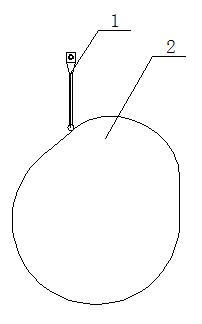

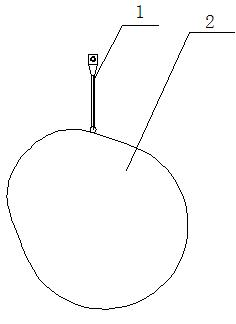

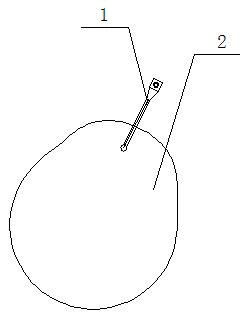

[0015] The probe should be calibrated before invoking the camshaft online measurement process. The calibration is divided into two steps. The first step is to use the tool setting instrument to adjust the offset between the center of the ruby measuring ball on the probe and the axis of rotation of the probe within 0.005mm. The second step is to calibrate the probe using a standard ring gauge. Calibrate the probe once a week with a standard ring gauge. If the calibration fails, use a tool setting instrument to readjust the probe so that the offset between the center of the ruby measuring ball on the probe and the axis of rotation of the probe is controlled within 0.005mm. Inside.

[0016] The first step, measurement and positioning during clamping: carry out axial and circumferential measurement and positioning of the camshaft blank; the camshaft online measurement process is to directly measure and position the camshaft blank in the axial and circumferential directions, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com