Polishing device for eliminating coining effect of lightweight reflecting mirror

A light-weight reflector and polishing device technology, applied in grinding/polishing equipment, optical surface grinders, grinders, etc., to achieve the effects of eliminating embossing deformation, simple control, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

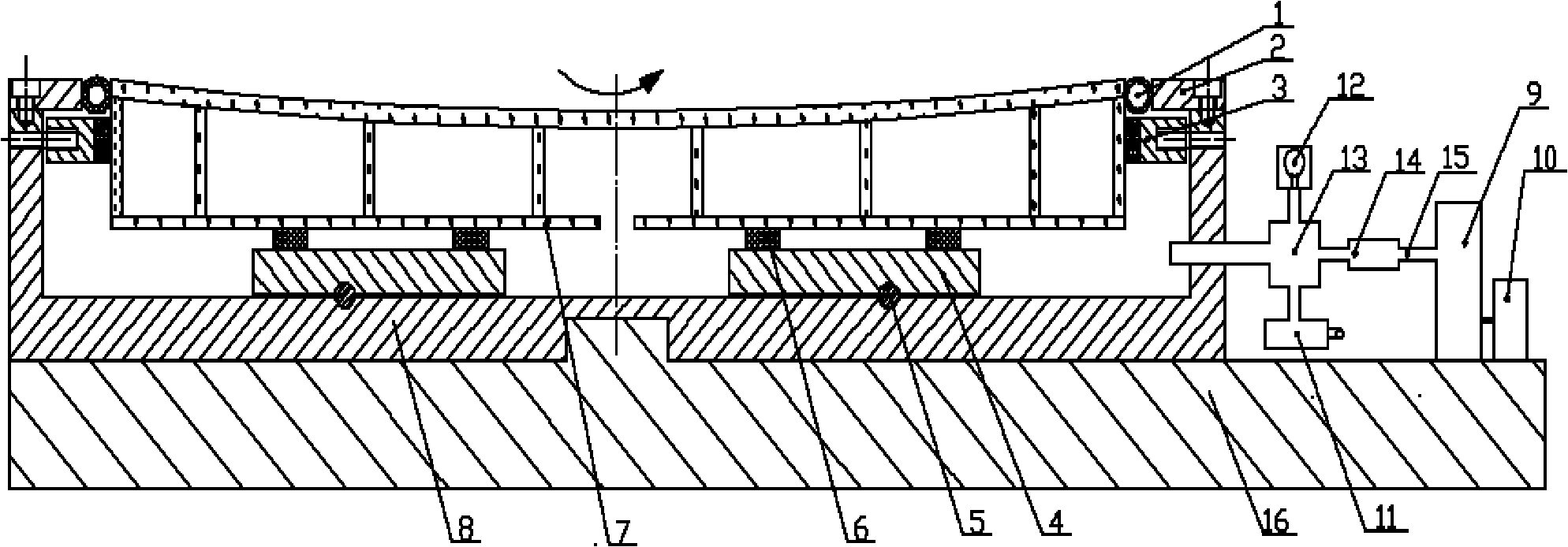

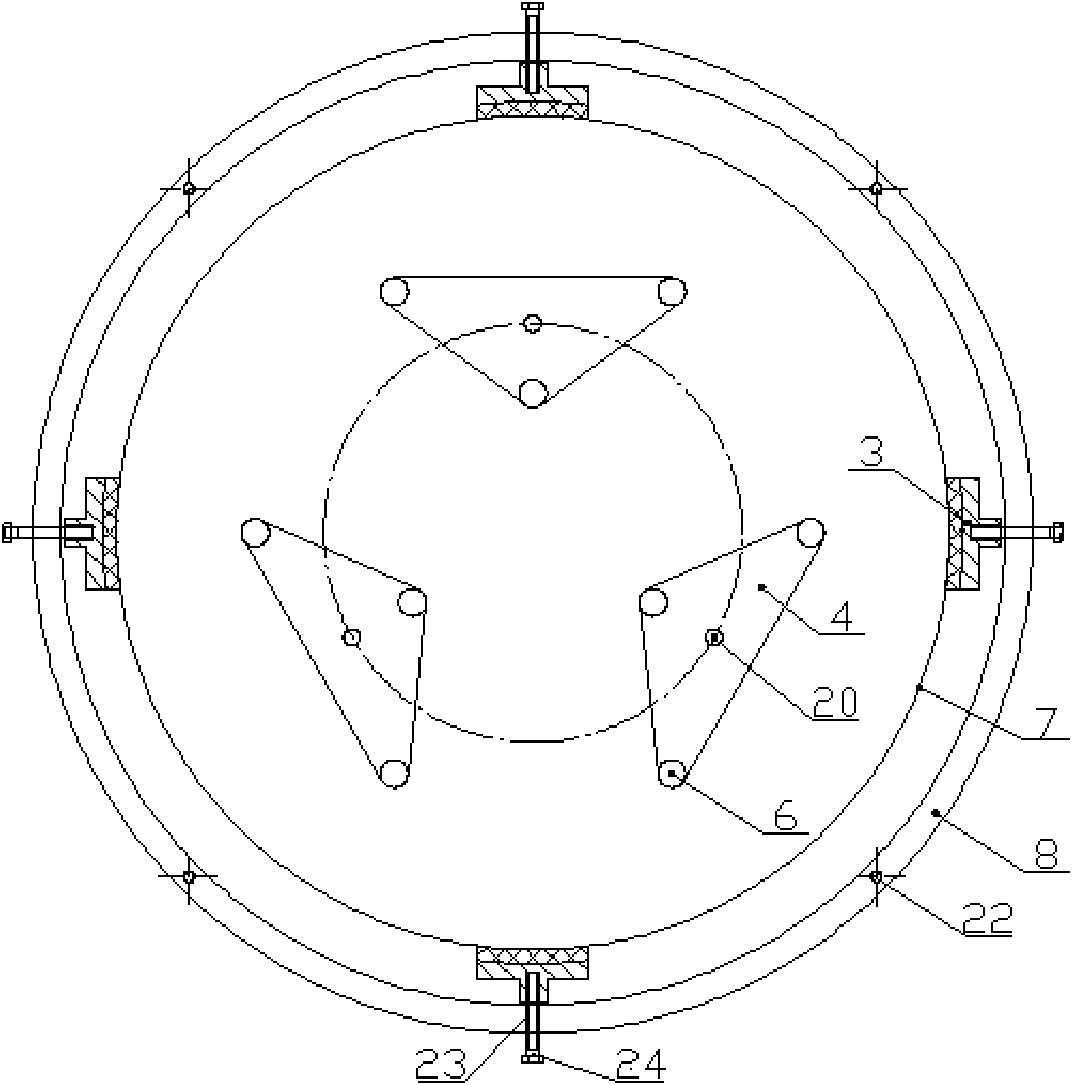

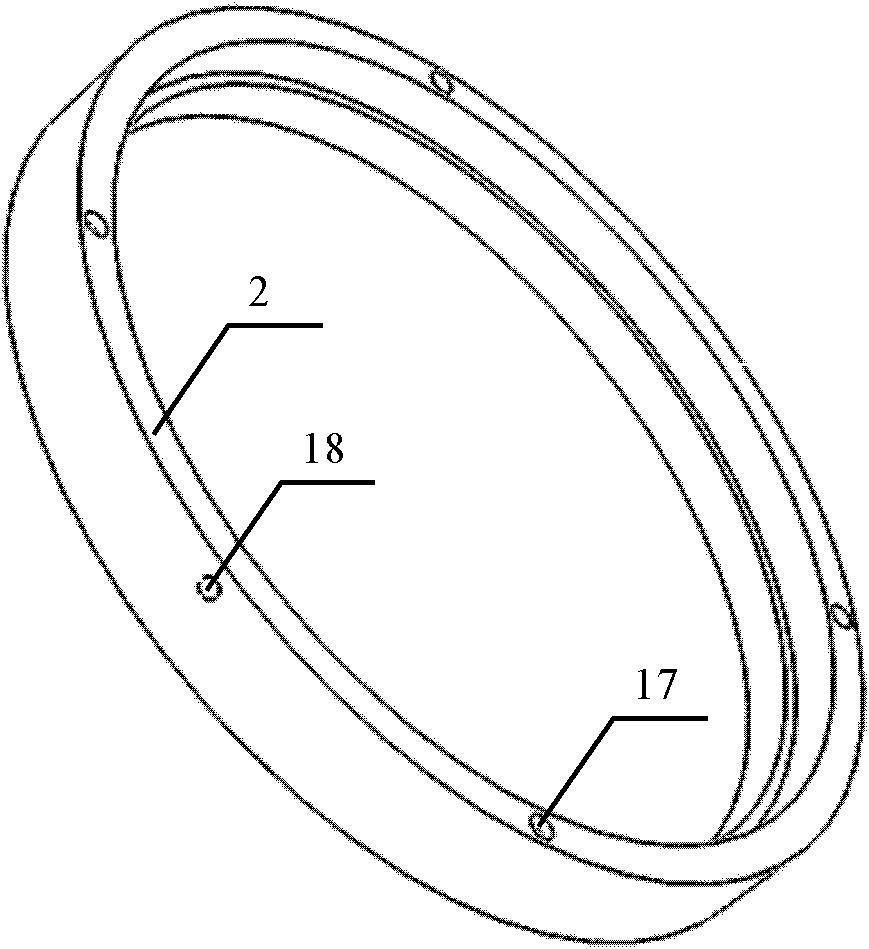

[0029] Such as figure 1 , 2 As shown, the present invention is made up of immersion type sealed polishing platform and precise inflation device. The immersion-type sealed polishing platform is composed of a sealed cylinder 8, a top cover 2, a support seat 4, a steel ball 5, an arc-shaped fixture 3 and an elastic sealing ring 1, and the precision inflation device is composed of a micro air pump 9, a DC power supply 10, a precision stop valve 14, The precise pressure relief valve 11, the membrane air pressure gauge 12, the four-way body 13 and the silicone tube 15 are composed.

[0030] Three triangular support seats 4 with hemispherical grooves at the center of gravity of the bottom side are placed on three steel balls 5 on the bottom surface of the inner cavity of the sealed cylinder 8, and three gaskets 6 are bonded to the upper surface of each triangular support seat 4 to form nine points The structure of the supporting seat; the lightweight reflector 7 is placed on the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com