Electric energy meter carrying manipulator suitable for meter box

A technology of electric energy meter and manipulator, applied in the field of electric energy meter transfer equipment, can solve the problems of incompatibility, high labor intensity, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

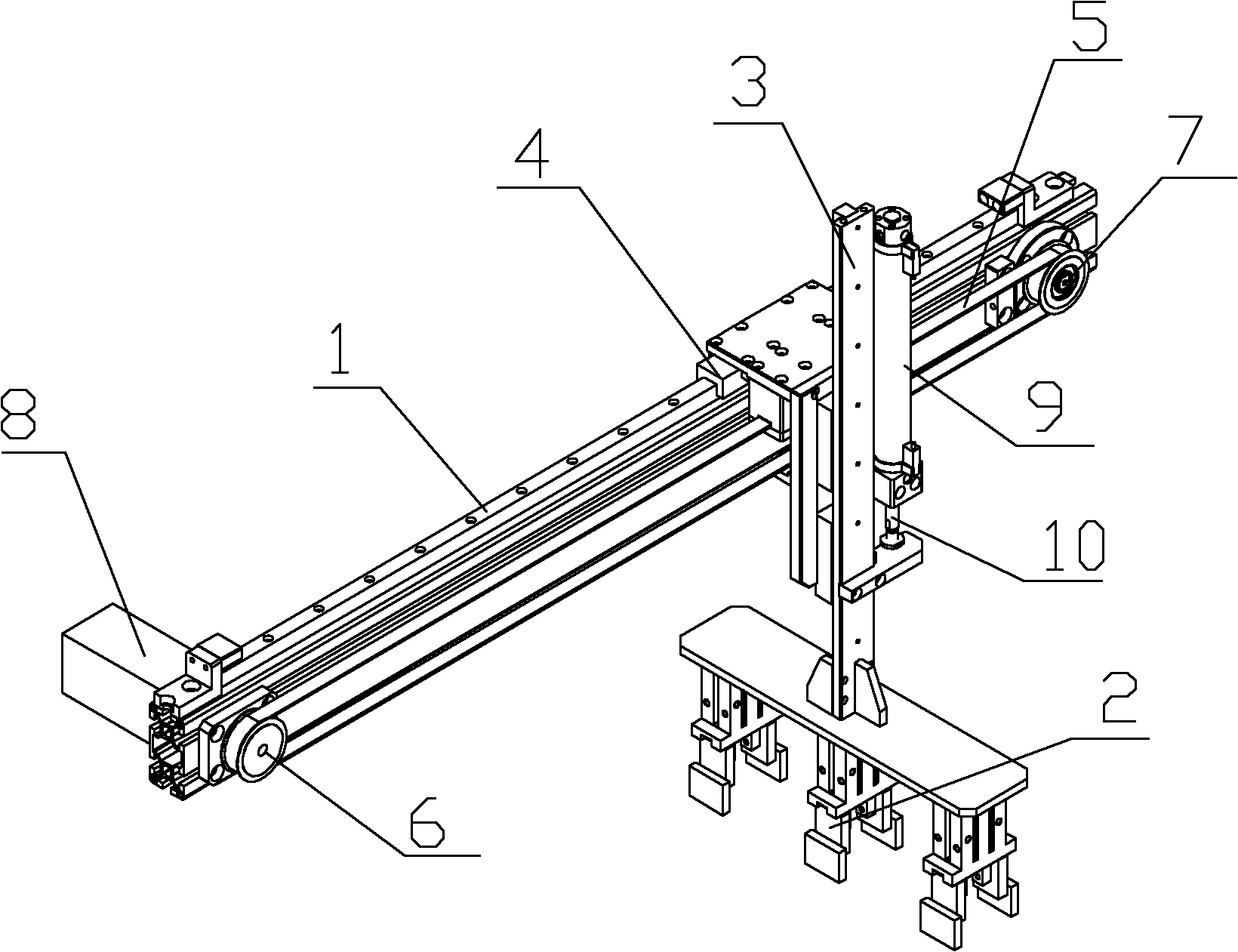

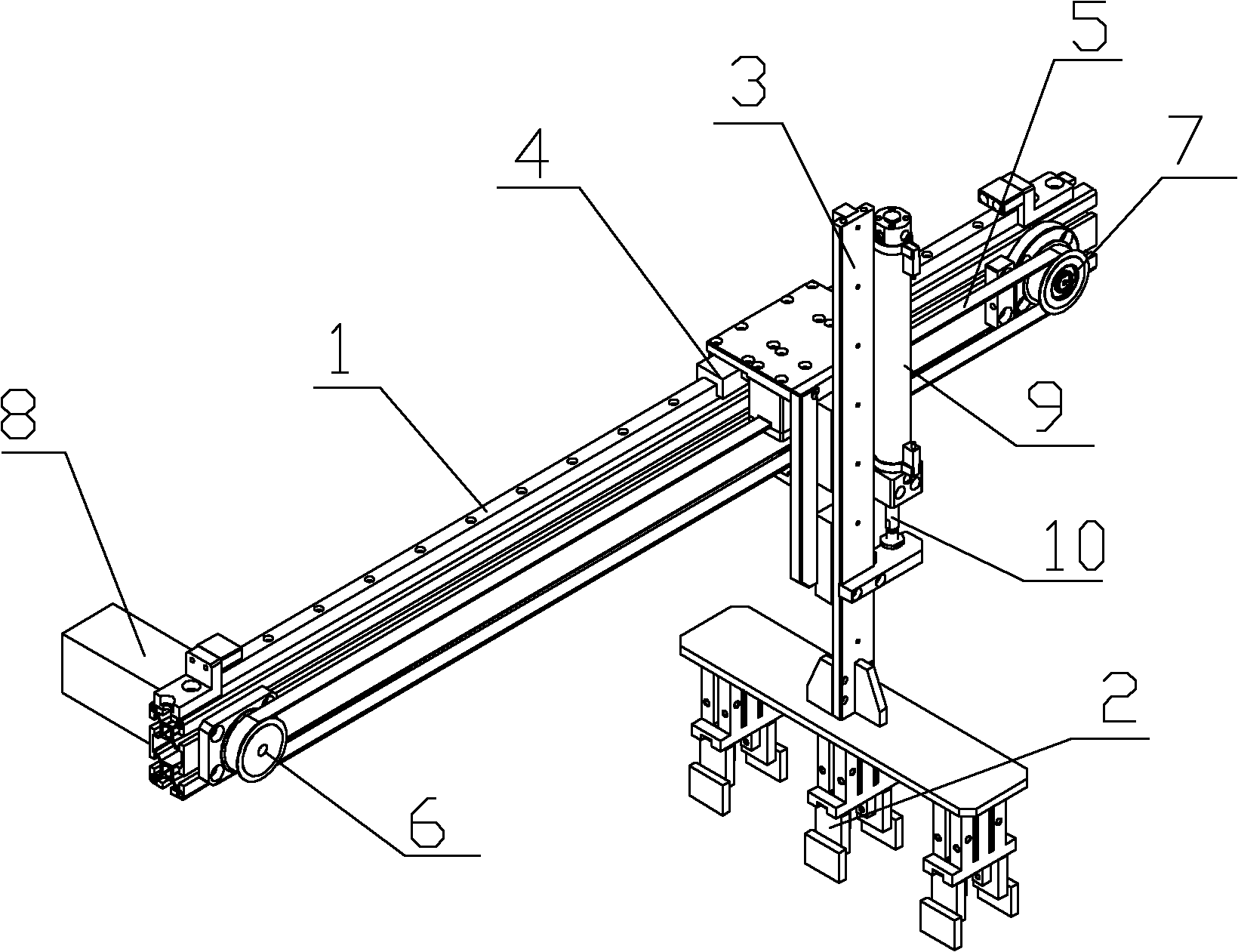

[0020] Such as figure 1 As shown, the electric energy meter handling manipulator suitable for the meter box described in this embodiment includes a frame 1 and three pneumatic grippers 2 for clamping the electric energy meter. The pneumatic grippers 2 are arranged on a longitudinal member 3 Above, the longitudinal member 3 is arranged on the guide rail of a transverse member 4 and is driven by a cylinder 9. The transverse member 4 is slidably connected to the frame 1 and has transmission teeth on it. The transverse member 4 The transmission teeth are engaged with a synchronous belt 5 toothed, and the synchronous belt 5 is sleeved on a driven wheel 7 and a driving wheel 6 connected to the motor 8, and the driving wheel 6 and the driven wheel 7 are fixed on the on rack 1. The cylinder barrel 9 of the air cylinder is vertically fixed on the transverse member 4 , and the piston rod 10 of the air cylinder is connected with the longitudinal member 3 . The bottom of the transverse ...

Embodiment 2

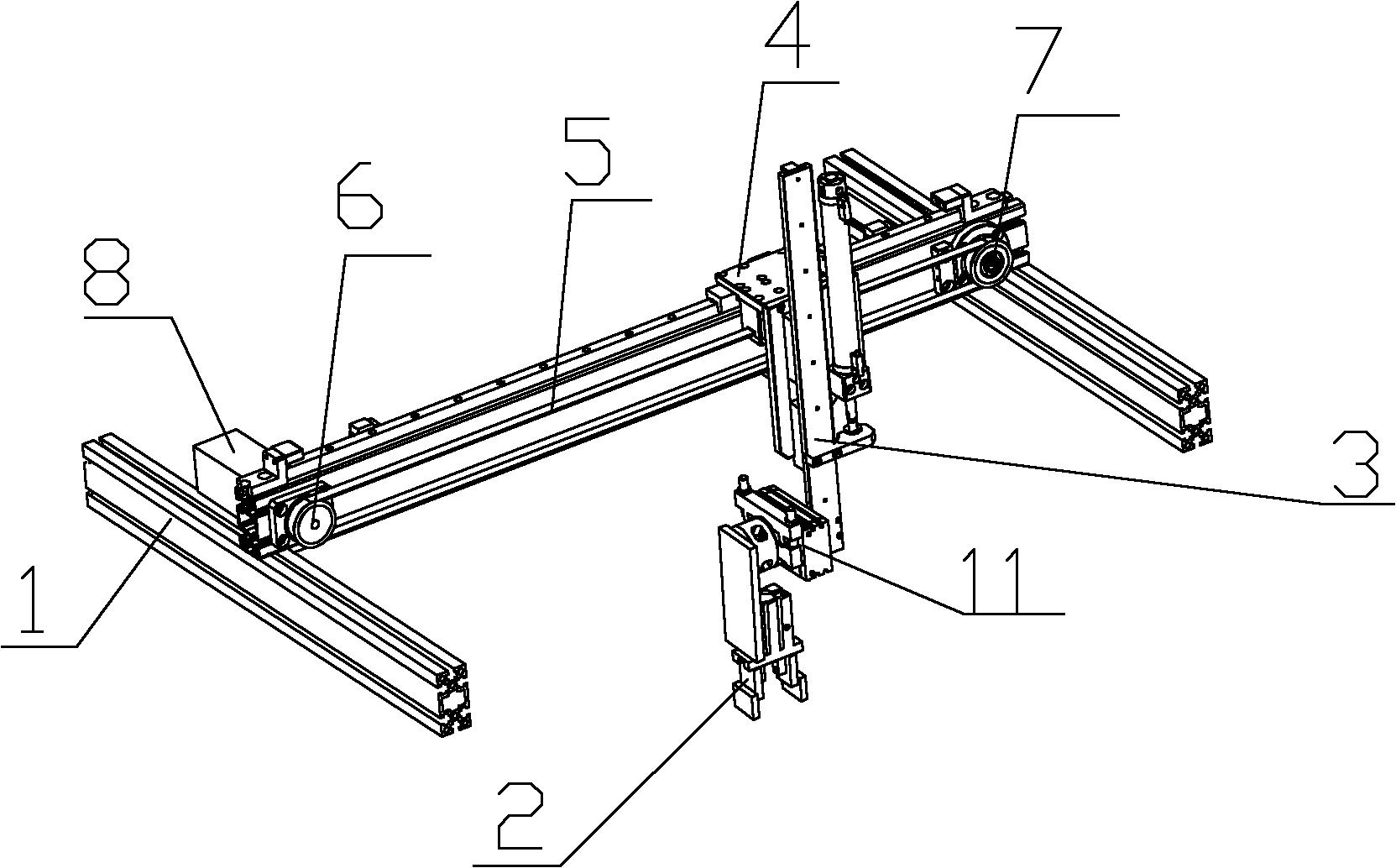

[0022] Such as figure 2 As shown, in this embodiment, a steering mechanism 11 is installed on the longitudinal member 3. The steering mechanism 11 is connected to the pneumatic gripper 2 and has a steering function to improve the flexibility of transporting the electric energy meter. In this embodiment, there is only one pneumatic gripper 2, which is suitable for the loading and unloading operation of the built-in single-row electric energy meter box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com