Bottom chord node fastening device of multi-suspend structure and fastening tension method thereof

A fastening device and multiple technology, applied in building structure, processing of building materials, construction, etc., can solve problems such as the size and distribution of internal forces inconsistent with the design, adverse effects on the mechanical properties of suspensive structures, and loss of prestress, etc., to achieve Good anti-corrosion effect, high construction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

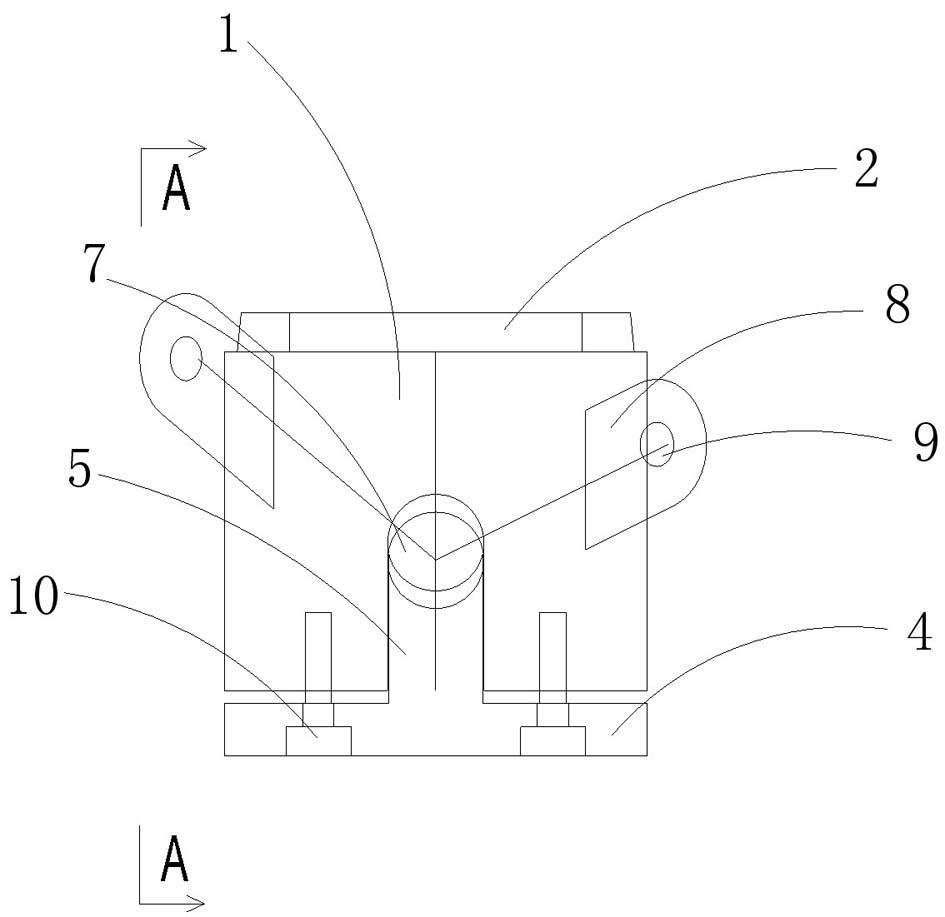

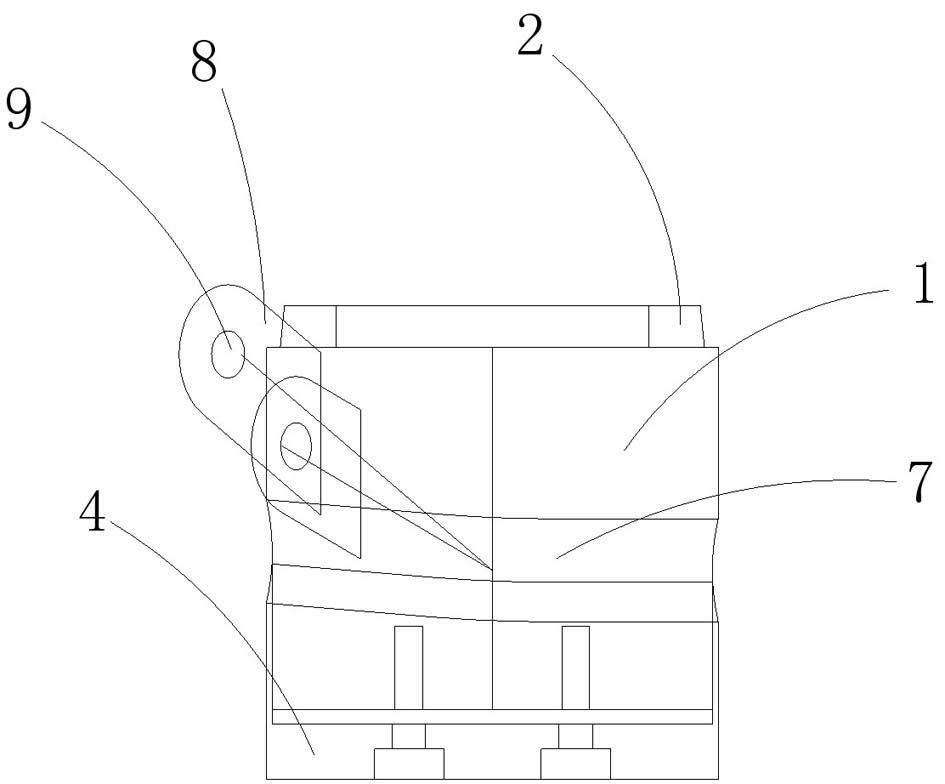

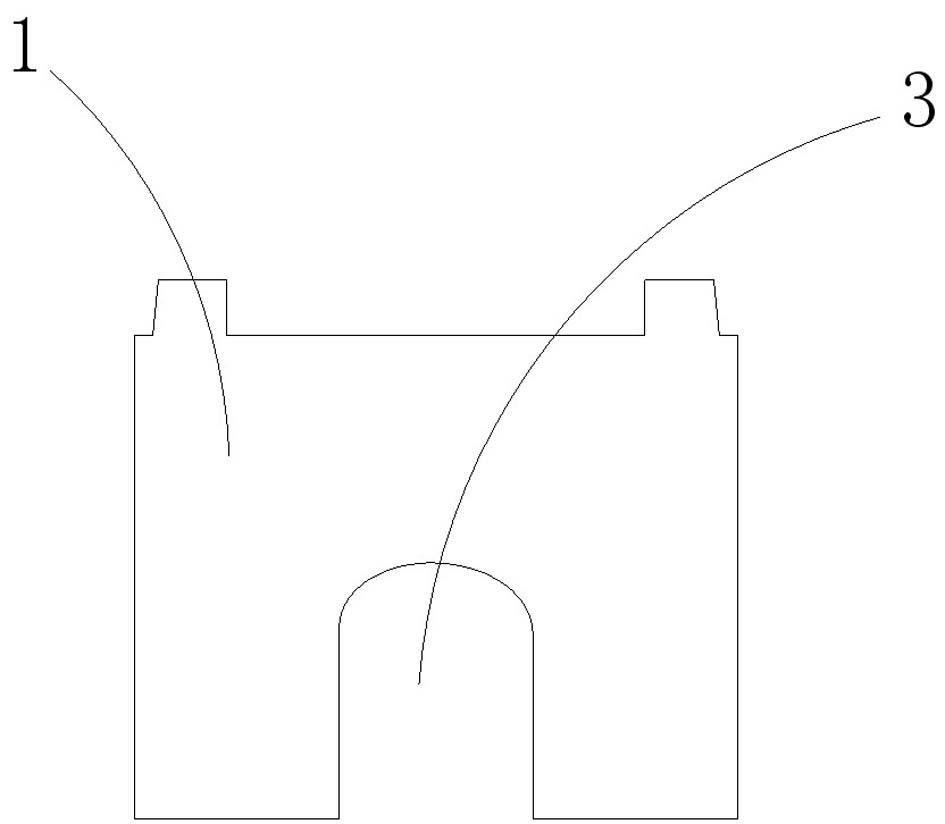

[0053] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 8 As shown, a lower chord node fastening device of a multiple chord support structure includes a strut connecting piece 1, the upper end of the strut connecting piece 1 is a strut transition step 2, and the middle part of the strut connecting piece 1 is set There is a groove 3 with an opening downward, and a cableway fixing seat 4 is fastened to match the brace connector 1. The bottom of the brace connector 1 and the cableway fixing seat 4 are cylindrical, and the brace connector 1 and the cableway fixing seat 4 is a steel casting, the middle part of the cableway fixing seat 4 is provided with a threading vertical bar 5, the cableway fixing seat 4 and the threading vertical bar 5 are integrated, and the upper end of the threading vertical bar 5 is a lower groove 6. The cable vertical rod 5 is matched with the groove 3, the groove 3 and the lower groove 6 form a cable tunnel 7, the cable tunnel ...

Embodiment 2

[0078] The fastening and tensioning method of the lower chord node of the multi-suspend structure proceeds according to the following steps:

[0079] (1), fastening:

[0080] ①. Strongly weld the connecting parts of the strut to the lower end of the strut;

[0081] ② Use the turntable to release the cables, and use the moving flat car method to gradually release the cables from one end of the truss to the other end, so that the cables can be moved to the tire frame in a straight line and lie flat;

[0082] ③. Use a traction jack to lift the cable at both ends of the truss. When the precise mark reserved for the cable is close to the lower end of the groove of the strut connector by 30mm, place the head of one end of the cable in place; during the lifting process, use 1 / 2 The distance at the span is the control target, start the oil pump at the other end of the truss, insert the reserved precise marks of the cables from bottom to top into the grooves of all the connecting part...

Embodiment 3

[0095] The fastening and tensioning method of the lower chord node of the multi-suspend structure proceeds according to the following steps:

[0096] (1), fastening:

[0097] ①. Strongly weld the connecting parts of the strut to the lower end of the strut;

[0098] ② Use the turntable to release the cables, and use the moving flat car method to gradually release the cables from one end of the truss to the other end, so that the cables can be moved to the tire frame in a straight line and lie flat;

[0099]③. Use a traction jack to lift the cable at both ends of the truss. When the precise mark reserved for the cable is close to the lower end of the groove of the strut connector by 50mm, place the head of one end of the cable in place; during the lifting process, use 1 / 2 The distance at the span is the control target, start the oil pump at the other end of the truss, insert the reserved precise marks of the cables from bottom to top into the grooves of all the connecting parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com