Suspended movable drill rod mud scraping device

A scraper and suspension type technology is applied in the field of suspension type mobile drill pipe mud scraper, which can solve the problems such as the coupling stuck at the lower end of the mud scraper, the inability to effectively scrape the mud, and the inability to complete the tripping smoothly. Eliminate potential safety hazards, easy installation and disassembly, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

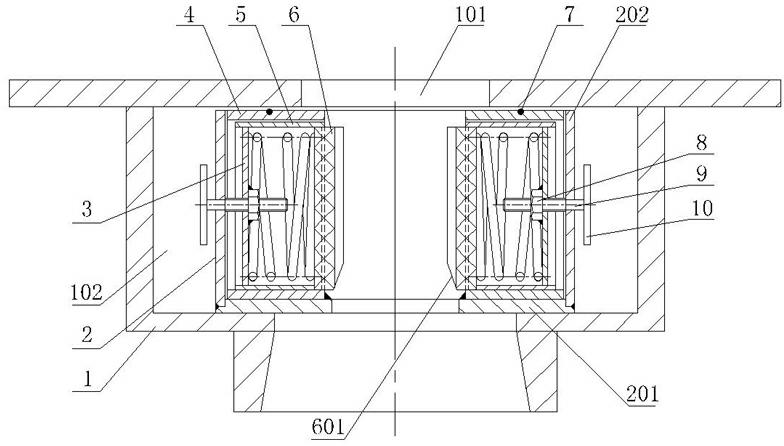

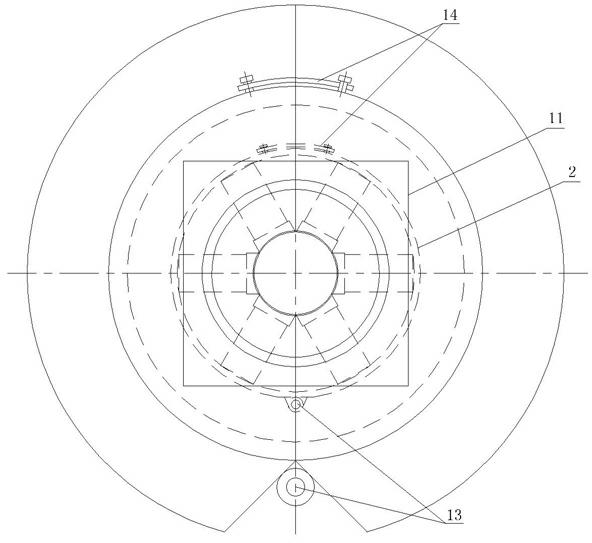

[0019] As shown in the figure, the suspended mobile drill pipe mud scraper has a shell 1, a drill pipe through hole 101 is arranged in the center of the shell 1, a cylindrical inner chamber 102 is arranged in the shell 1, and a 1 The lower part is welded with a square socket 11 for inserting into the center of the drill disk bushing. A suspension seat 2 is provided in the inner cavity 102 of the casing 1. The suspension seat 2 is cylindrical and consists of an annular bottom plate 201 and a sleeve welded on the outer edge of the bottom plate 201. Tube 202, the housing 1 and the suspension seat 2 are respectively a split structure formed by two symmetrical parts hinged by the hinge shaft 13, and the middle part of the outer wall of the housing 1 and the suspension seat 2 corresponds to the hinge shaft 13. The other side is respectively provided with lock buckles 14 for locking.

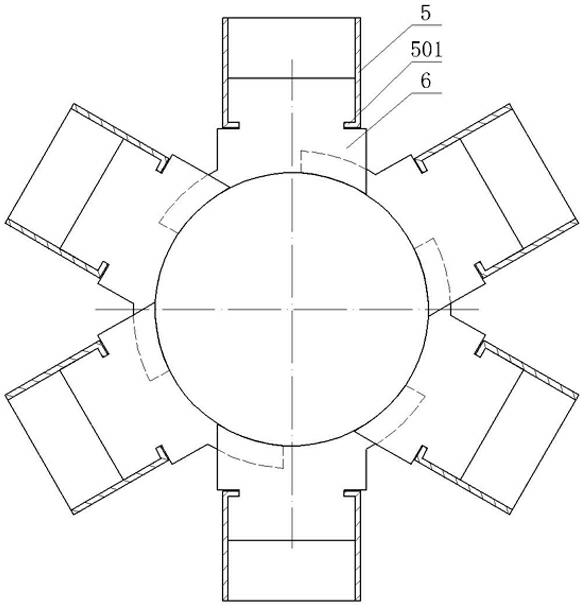

[0020] Fixed square sleeves 4 are uniformly welded in the suspension seat 2 along its circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com