Method for manufacturing spiral swivel vertical shaft wind power generator device

A wind turbine and vertical axis technology, applied in wind turbine components, wind engines, wind engines at right angles to the wind direction, etc., can solve the problems of low utilization rate of wind energy, vertical axis wind turbines are not taken seriously, etc. Achieve the effects of easy maintenance, lower center of gravity and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

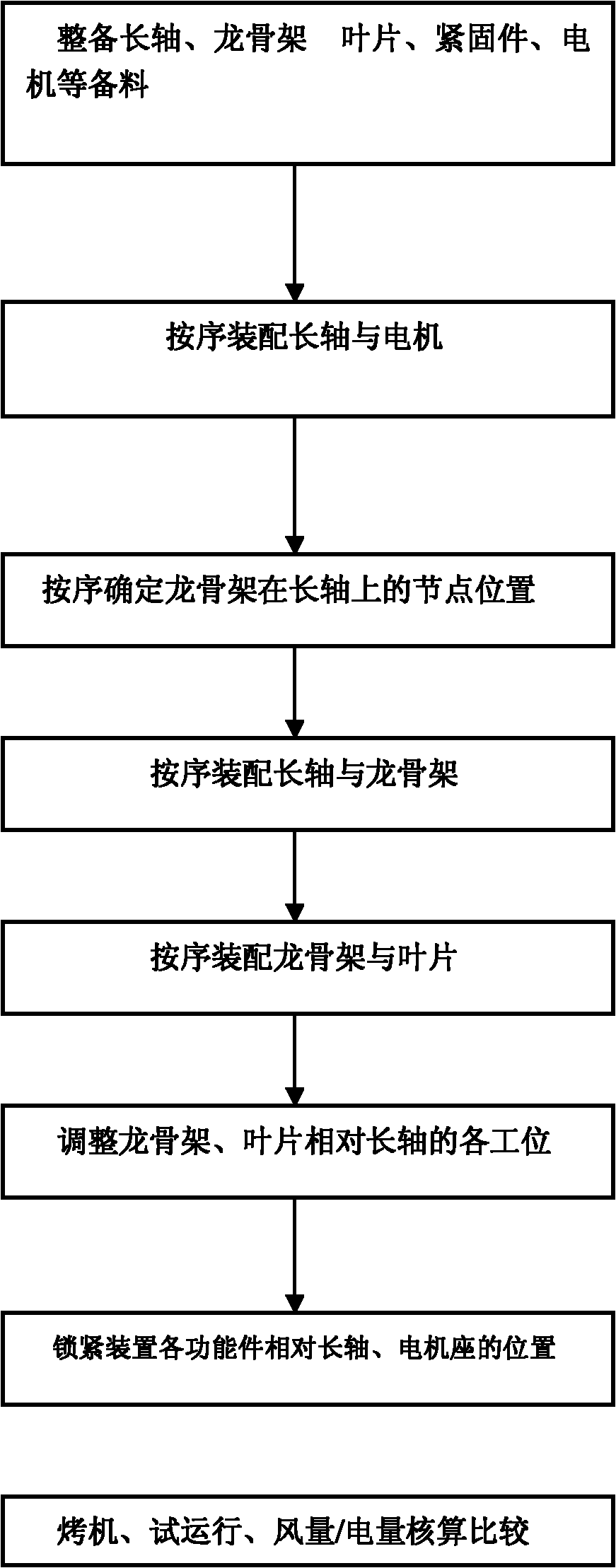

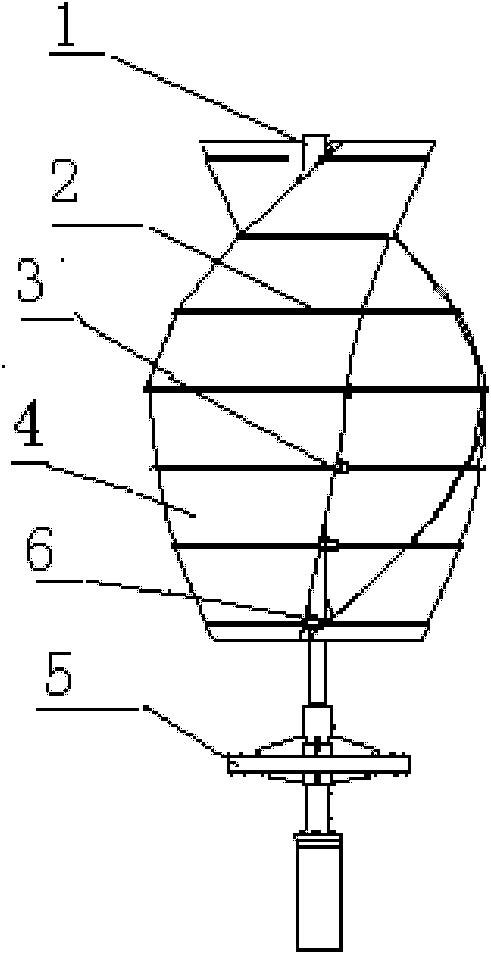

[0013] With reference to the above drawings, the present invention discloses a method for manufacturing a helical rotor vertical axis wind power generator. This method does not involve the specific manufacture of each functional part of the device, but more emphasis is placed on the consideration of the parameters of each functional part during the preparation of the device and the shape requirements during installation and operation.

[0014] Prepare a motor, a shaft with a length set according to the wind resource area, such as preparing a long shaft with a length of 200 cm and a diameter of 10 cm, at least two or more keel brackets, and at least two or more blades And at least two or more fasteners; after that, connect the motor with the long axis bushing so that the long axis is perpendicular to the motor base, then install the keel bracket horizontally relative to the vertical direction of the long axis and connect it to the long axis with fasteners Fix the connection, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com