Hypoid gear transmission mechanism

A hypoid gear and transmission mechanism technology, which is applied in transmission boxes, gear lubrication/cooling, mechanical equipment, etc., can solve the problems of large layout space of transmission mechanism, large loss of kinetic energy by churning oil, and impact on vehicle lightweight, etc. Effects of miniaturization and light weight, space saving, and layout space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

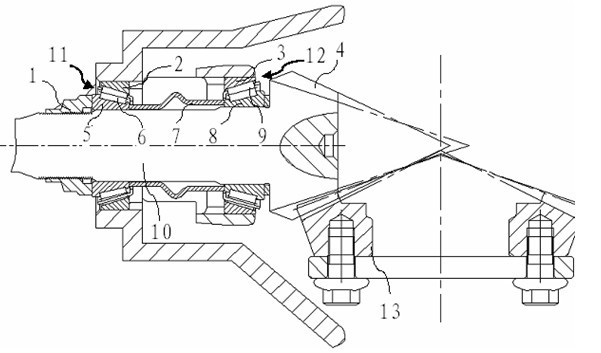

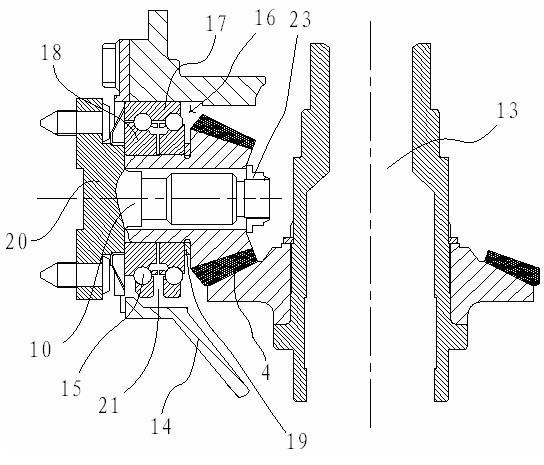

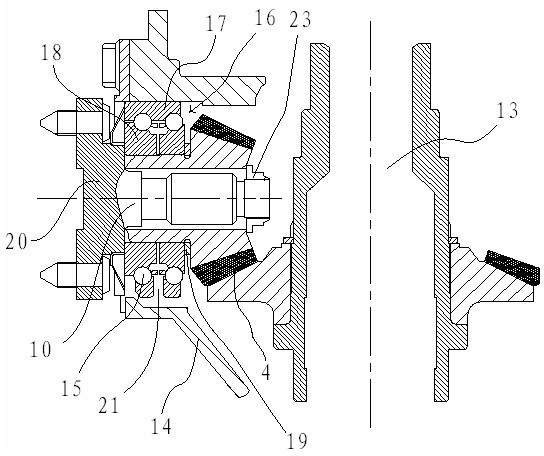

[0018] Such as figure 2 As shown, the hypoid gear transmission mechanism of this embodiment includes a driving shaft 10 and a driven shaft 13 arranged in a housing 14 at an intersection angle of 90 degrees. The driving shaft 10 and the driven shaft 13 utilize a hypoid gear pair 4 Connection; the key point is that it also includes a double-row angular contact ball bearing 16 axially limited to the shaft body of the drive shaft, the outer ring 17 of the double-row angular contact ball bearing is offset against the inner wall of the housing 14, and the inner ring of the double-row angular contact ball bearing 18 is sleeved on the shaft body of the driving shaft 10; the double row angular contact ball bearing is provided with an oil passage 21 connecting its interior with the inner cavity of the housing, and the oil passage 21 is the surface of the outer ring 17 via the double row angular contact ball bearing And the side part enters the through hole of the cavity between the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com