Light emitting diode (LED) reflective cup

A reflective cup and reflective surface technology, which is applied in the field of reflective cups, can solve the problems of high installation and wiring costs, high electricity costs, and uneven illumination, and achieve low installation and wiring costs, low electricity costs, and good heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

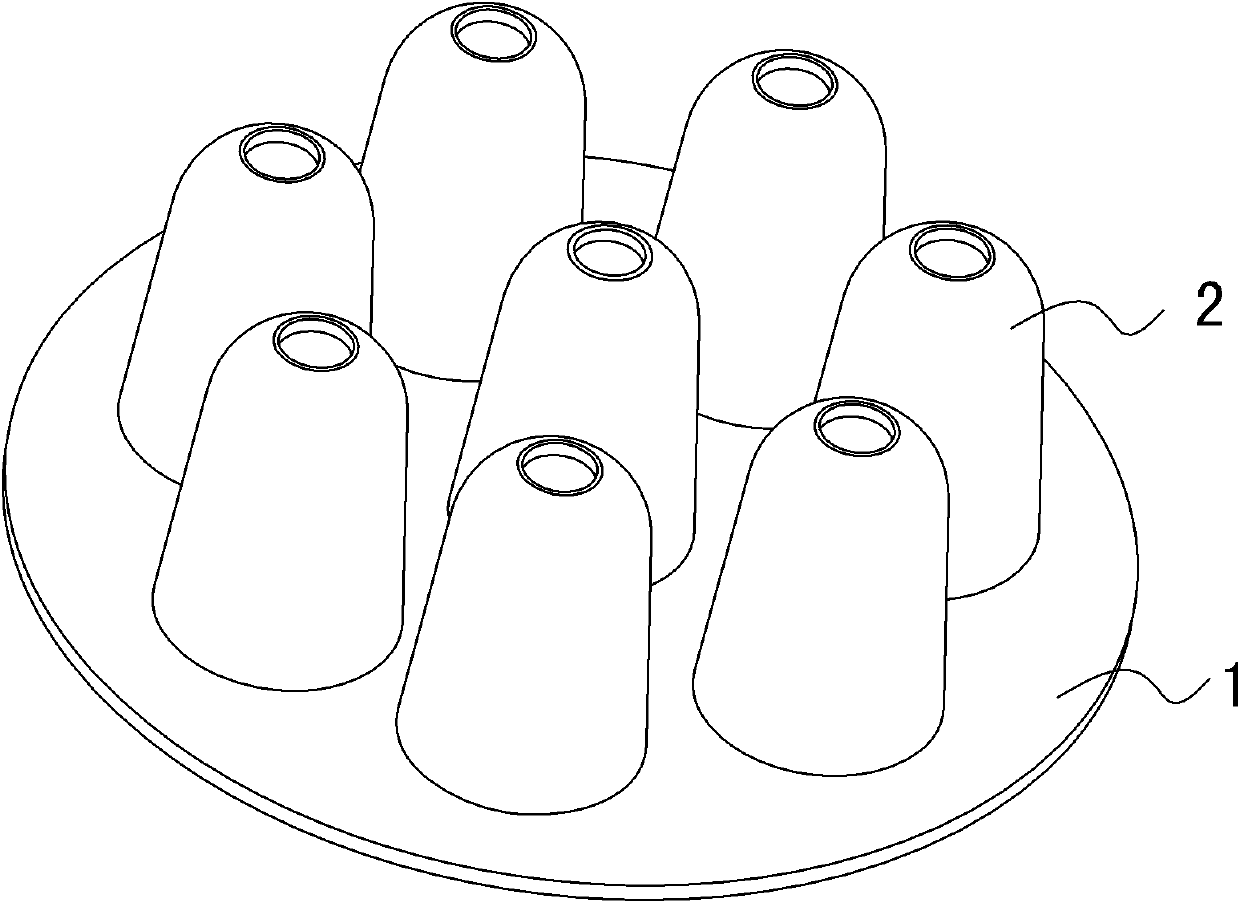

[0026] refer to figure 1 with figure 2 , this embodiment one discloses an LED reflective cup, including a base 1 and a reflective cup 2 arranged on the base 1, wherein:

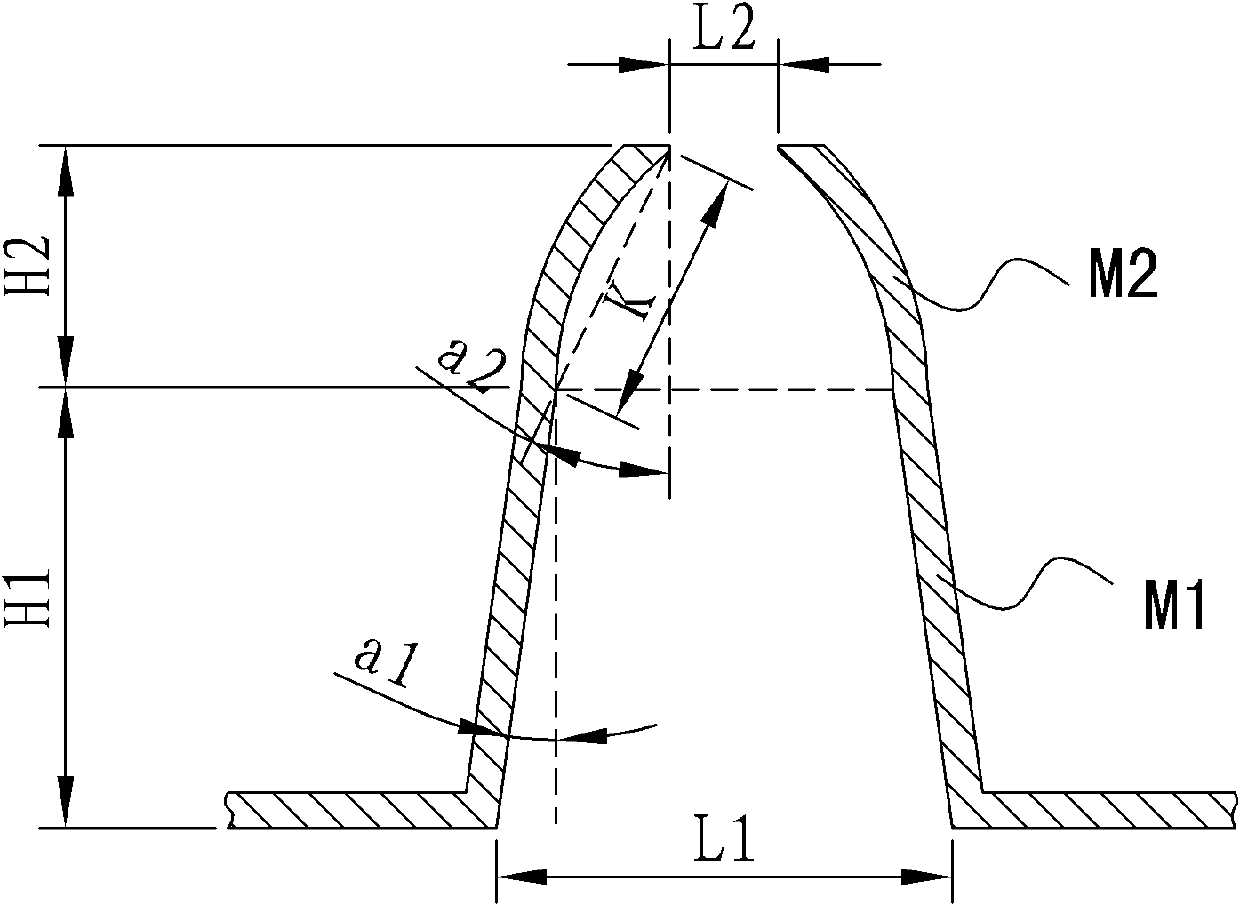

[0027] The reflective cup 2 is composed of one set in the middle of the base 1 and seven reflective cups uniformly distributed on the outside of the base 1 along the circumferential direction. Each of the reflective cups 2 is provided with a hollow cup cavity, and the cup cavity includes a curved reflective surface M2 and a diagonal reflective surface M1 along the projection direction of the LED light. It is defined that the curved reflective surface M2 is formed by a curve around the center The surface formed by turning the line defines that the oblique line reflective surface M1 is a surface formed by revolving an oblique line around the central line. The end of the curved reflective surface M2 close to the LED light source forms a light inlet, and the end of the oblique reflective surface M1 away from t...

Embodiment 2

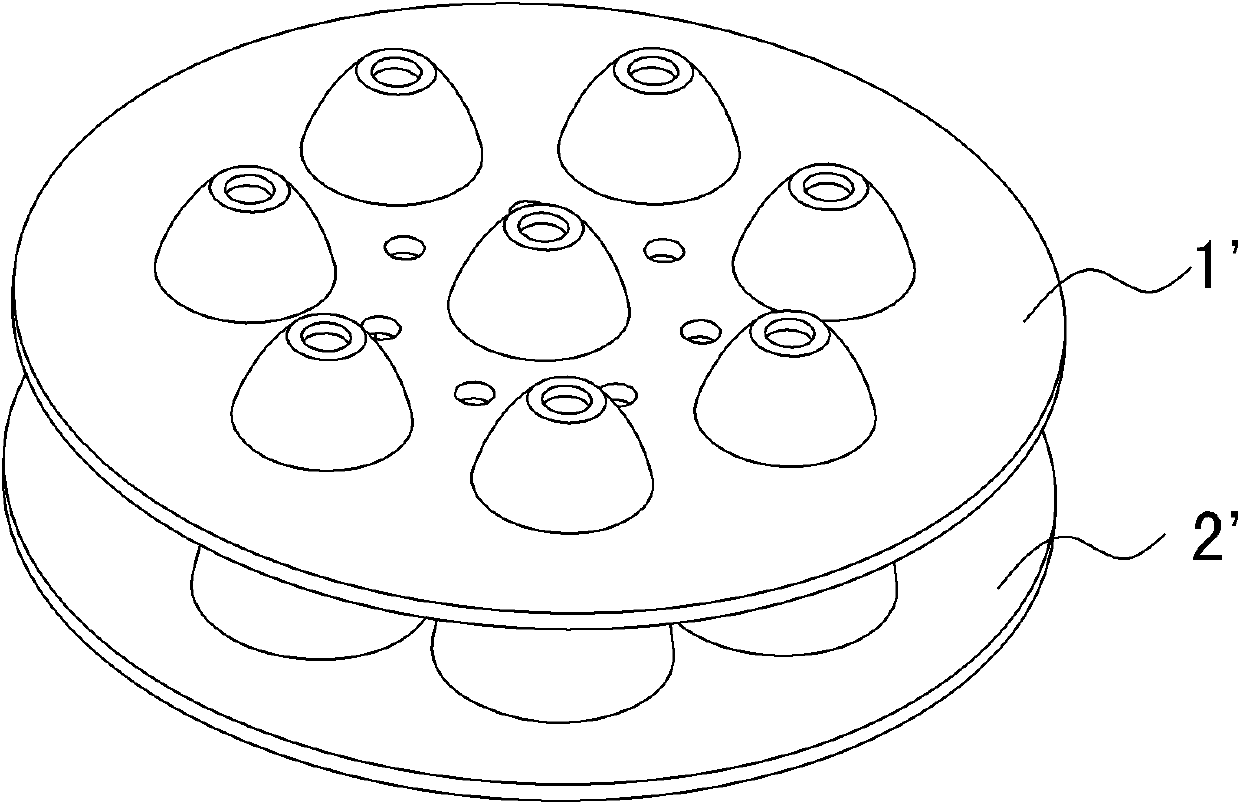

[0031] refer to image 3 with Figure 4 , the second embodiment discloses an LED reflective cup, an upper reflective cup 1' and a lower reflective cup 2', wherein:

[0032] The upper reflective cup 1' is set on the lower reflective cup 2' along the projection direction of the LED light. The upper reflective cup 1' includes a base 11' and eight reflective cups 12', and the reflective cups 12': one set in the middle of the base 11', and the other seven are evenly distributed on the outside of the base 11' along the circumferential direction. The lower reflective cup 2' includes a base 21' and eight reflective cups 22', the diameter of the base 21' is the same as that of the base 11', and the reflective cup 12' and the reflective cup 22' are connected up and down and correspond to each other; the LED light comes from the reflective cup 12' pass to reflective cup 22'. The upper reflector 1' is provided with 6 screw holes 13', and the lower reflector 2' is provided with 6 studs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com