Device and method for monitoring tensioning states of scraper conveyor chains

A scraper conveyor and chain technology, applied in the direction of tension measurement, etc., can solve the problems of lack of multi-information comprehensive processing and effective use, reliability, accuracy and practical defects, so as to ensure safe operation, eliminate limitations, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

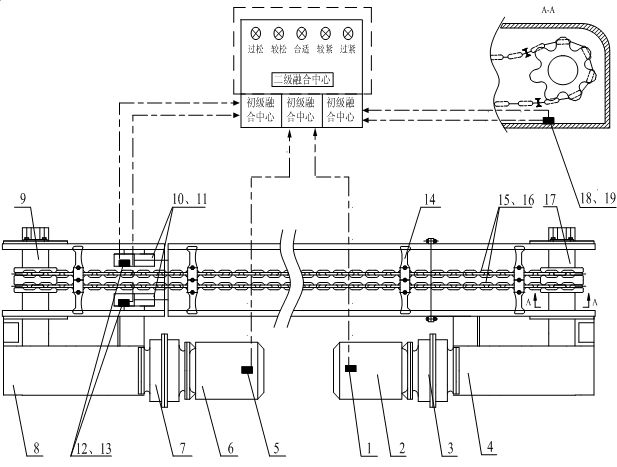

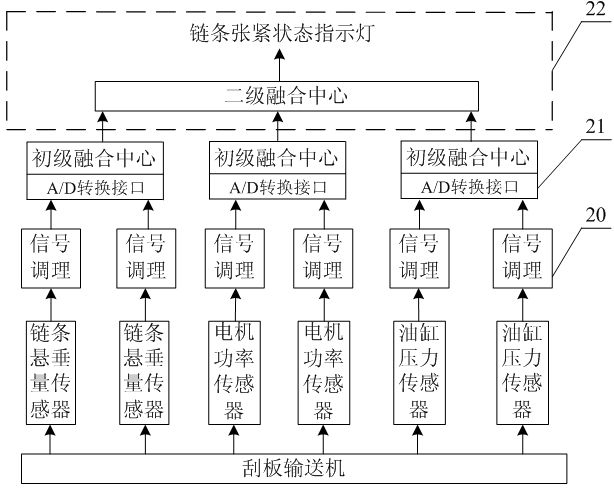

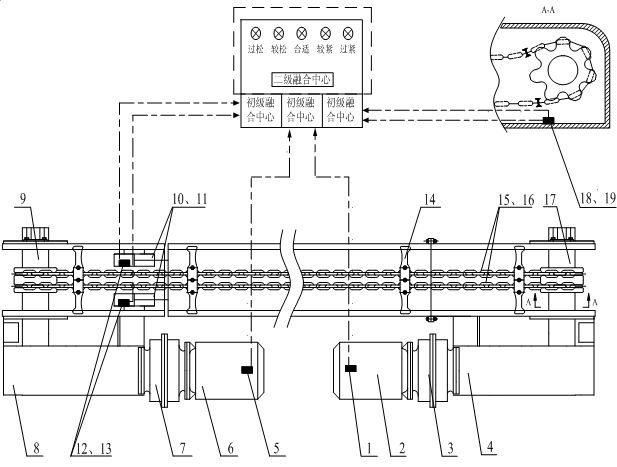

[0025]Embodiment 1: The device for monitoring the tension state of the chain is: including a head power transmitter 1, a head drive motor 2, a head hydraulic coupler 3, a head reducer 4, and a tail power transmitter 5 , tail drive motor 6, tail hydraulic coupler 7, tail reducer 8, tail sprocket assembly 9, first tail telescopic oil cylinder 10, second tail telescopic oil cylinder 11, first pressure sensor 12, Second pressure sensor 13, scraper 14, first chain 15, second chain 16, machine head sprocket assembly 17, first overhang sensor 18, second overhang sensor 19, signal conditioning unit 20, primary fusion center 21 And the chain state display controller 22, the head power transmitter 1 is connected on the head drive motor 2, the head drive motor 2 is connected with the head reducer 4 through the head hydraulic coupler 3, the head sprocket assembly 17 is connected with the nose reducer 4; the tail power transmitter 5 is connected with the tail drive motor 6, and the tail dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com