Novel method for testing durability of track tensioning device of hydraulic excavator

A hydraulic excavator, durability test technology, applied in the direction of measuring device, strength characteristics, using repeated force / pulsating force to test the strength of materials, etc., can solve the problem of unable to reflect the durability performance of pistons and cylinders, to save auxiliary The effect of hydraulic cylinders and simplified test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with principle diagrams and specific operation examples.

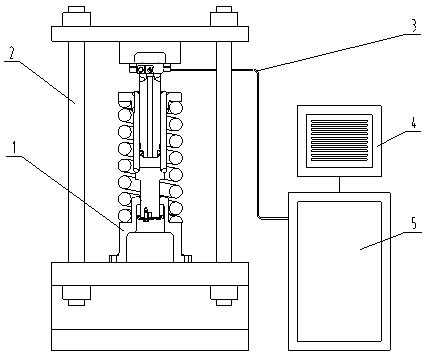

[0022] The invention is a durability test method of a new hydraulic excavator crawler belt tensioning device. figure 1 It is a schematic diagram of the connection of the test equipment of the present invention. In this embodiment, the test object is a tensioning device for a hydraulic excavator of 5.5 tons to 70 tons designed and produced by Sany Heavy Machinery Company. The test program and equipment should be able to cover this interval All products within. refer to figure 1 As shown, the track tensioning device 1 participating in the test is placed on the test frame 2, and the test frame 2 can be adapted to the track tensioning device 1 of the above-mentioned various types of hydraulic excavators. The tightening device 1 is connected to a hydraulic pump station 5 with an operation and control system 4 through an oil supply line 3 . The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com