Time-constraint-based scheduling optimization method for machining production process

A production process, time-constrained technology, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

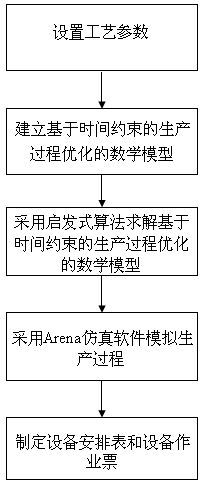

[0054] The steps of the optimal scheduling method for machining production process based on time constraints of the present invention are as follows:

[0055] 1) Process analysis to obtain the required data;

[0056] 2) According to the process analysis, describe the problem;

[0057] 3) According to the description of the problem, establish a mathematical model that can reflect the actual problem;

[0058] 4) Solve the established mathematical model according to the obtained data;

[0059] 5) According to the solution results, simulate the production process;

[0060] 6) Formulate an optimization and improvement plan for the machining production process.

[0061] Step 1) Process analysis:

[0062] The machining method refers to the process of directly changing the shape, size and surface quality of the blank in a certain order to make it a qualified part. The machining process is composed of many processes, including turning, milling, drilling, boring and grinding. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com