Co-simulation method of levelling system of hydraulic supporting platform based on virtual prototype

A hydraulic support platform and virtual prototype technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficulty in realizing dynamic simulation of the whole machine model, and achieve simplified inspection and debugging process, low cost, and improved development. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

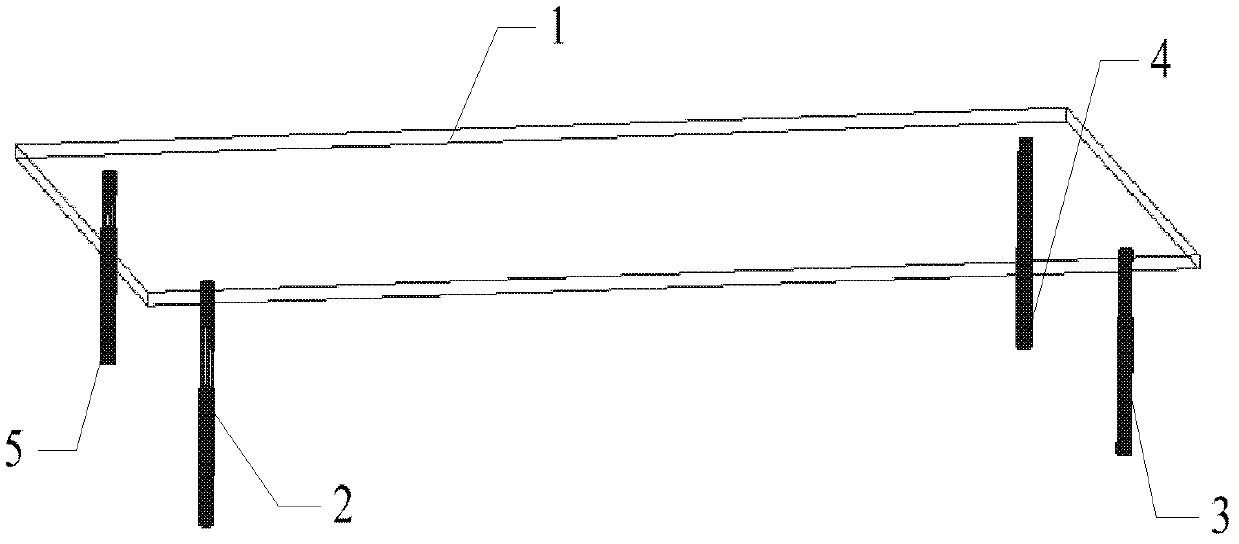

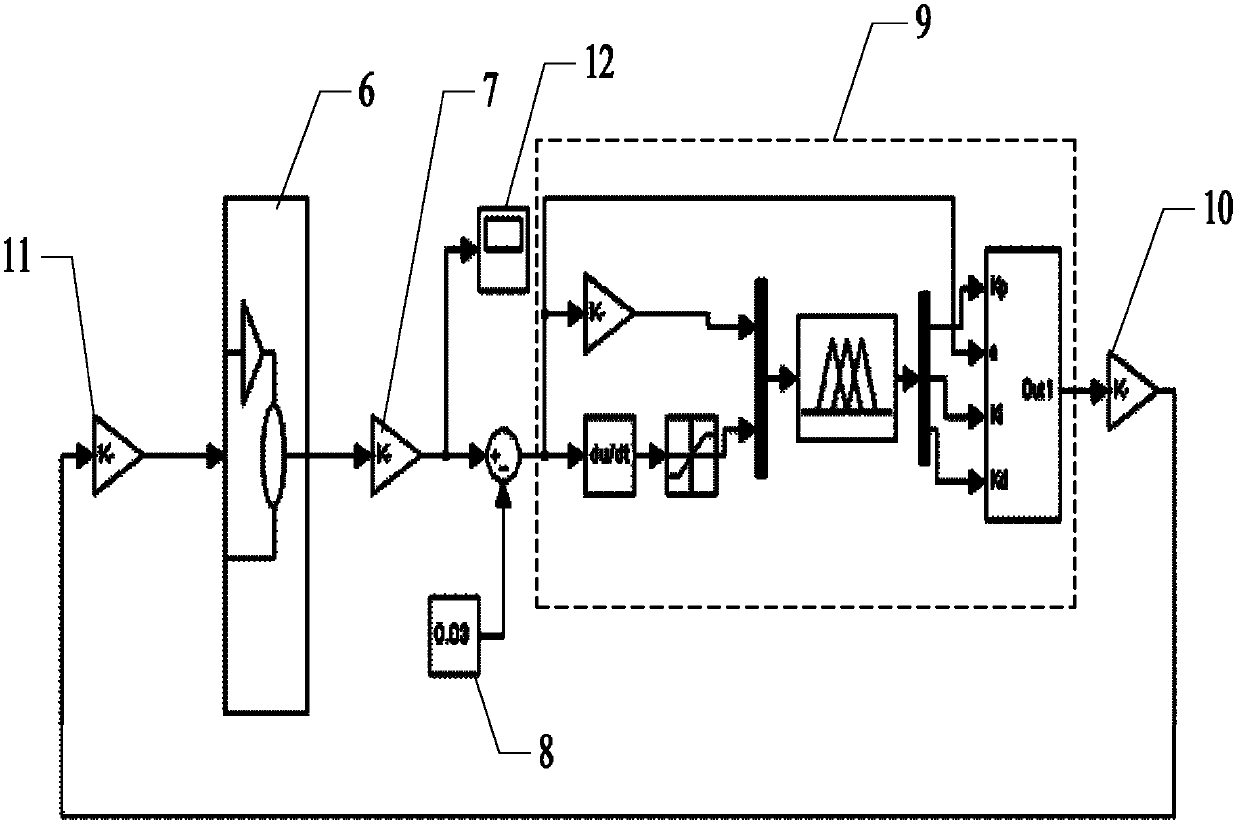

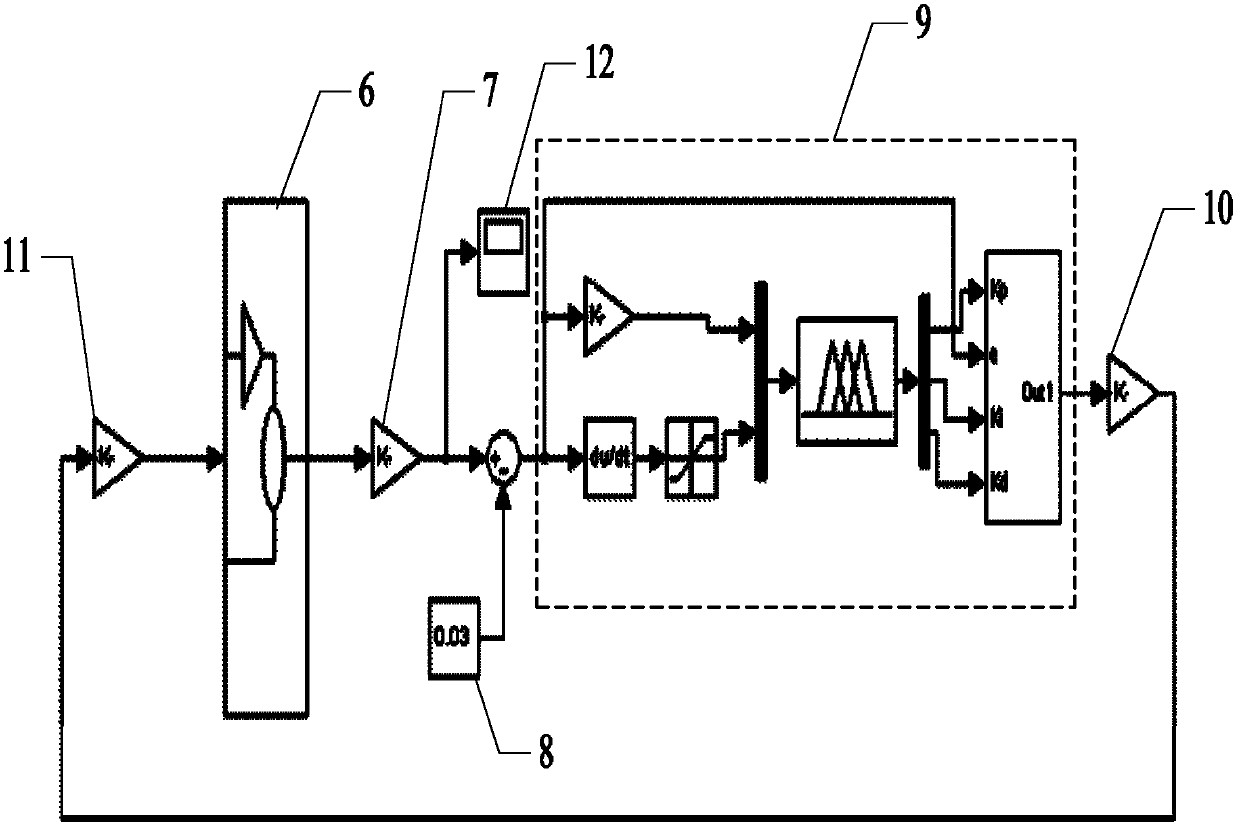

[0014] see Figure 1-2 , the implementation method of the present invention is as follows:

[0015] Step 1: Establish a three-dimensional solid model of the four-point hydraulic support platform. Firstly, a precise four-point hydraulically supported platform is established in the professional 3D modeling software SolidWorks. Since the 3D drawing tools provided by ADAMS cannot meet the needs of drawing, as a preprocessor of modeling, a 3D solid model is established in SolidWorks. The three-dimensional solid model of the four-point hydraulic support platform is as follows: figure 1 As shown, it is composed of a platform 1 and four hydraulic outriggers 2, 3, 4, 5, and the inclination angle between the platform and the horizontal plane is controlled by the expansion and contraction of the four hydraulic outriggers 2, 3, 4, 5.

[0016] Step 2: Establish the dynamic mechanical model of the virtual prototype, import the 3D solid model established in the solid modeling software int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com