Drive circuit with current balance for CCFL (Cold Cathode Fluorescent Lamp) tubes

A driving circuit, current balance technology, applied in the direction of instruments, static indicators, etc., can solve the problem that the current balance of CCFL lamps cannot be guaranteed, and achieve the effect of consistent lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

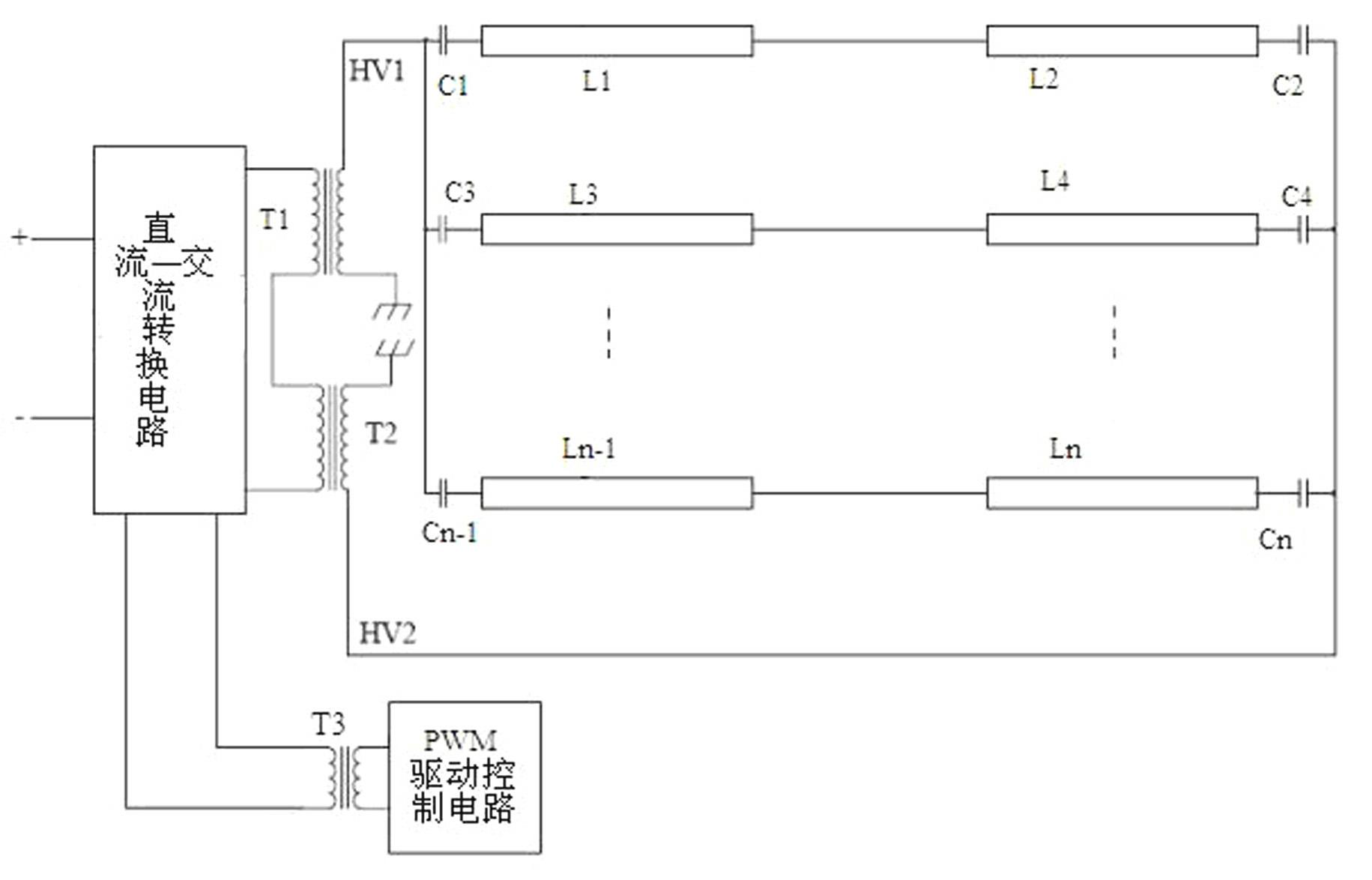

[0014] The present invention provides a drive circuit for CCFL tubes in an LCD backlight module. The drive circuit includes a current balance circuit that equalizes the current flowing through each CCFL tube, so that the luminous brightness of each CCFL tube is equal , So as to ensure that the LCD backlight module has uniform and sufficient brightness.

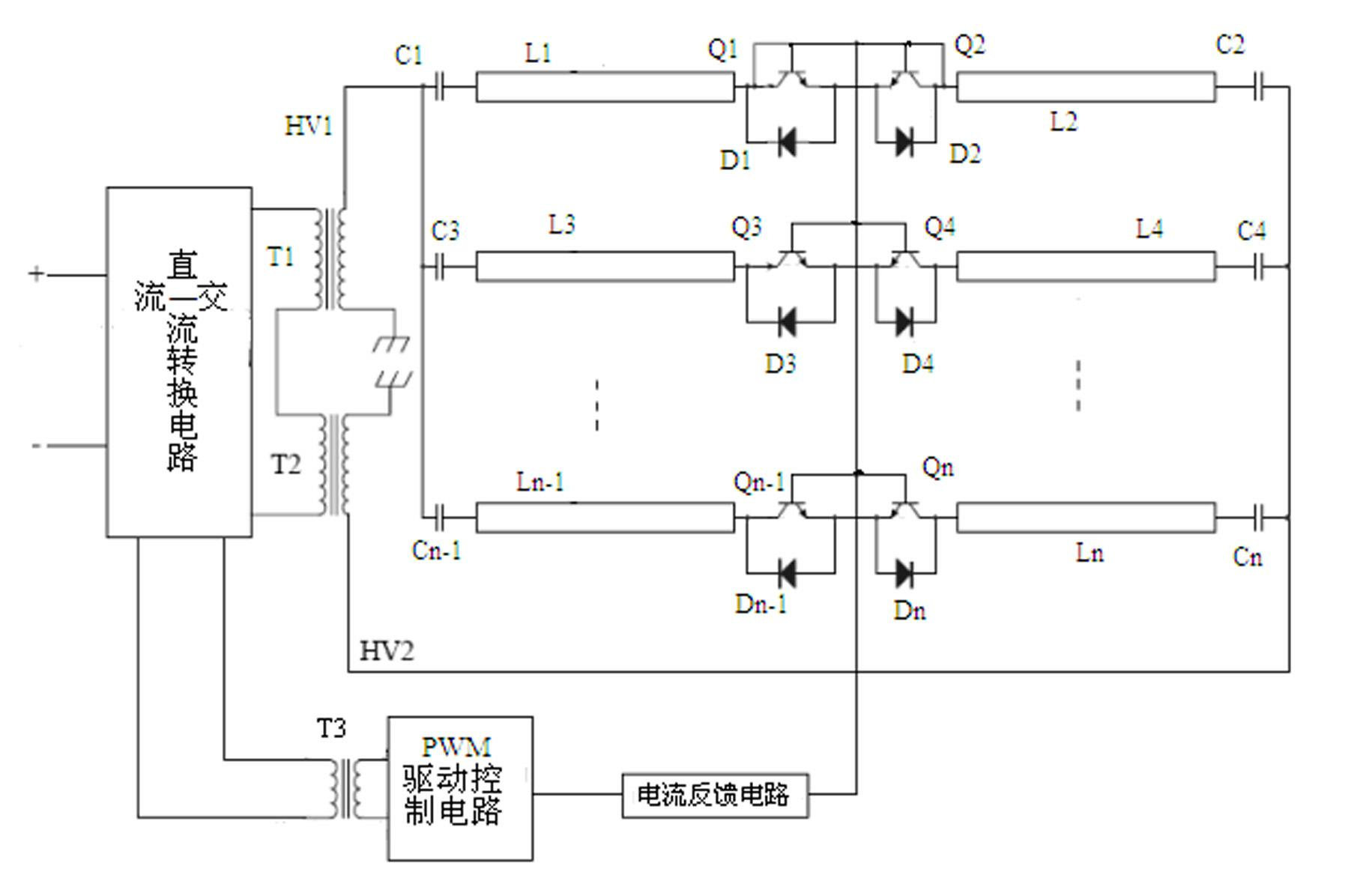

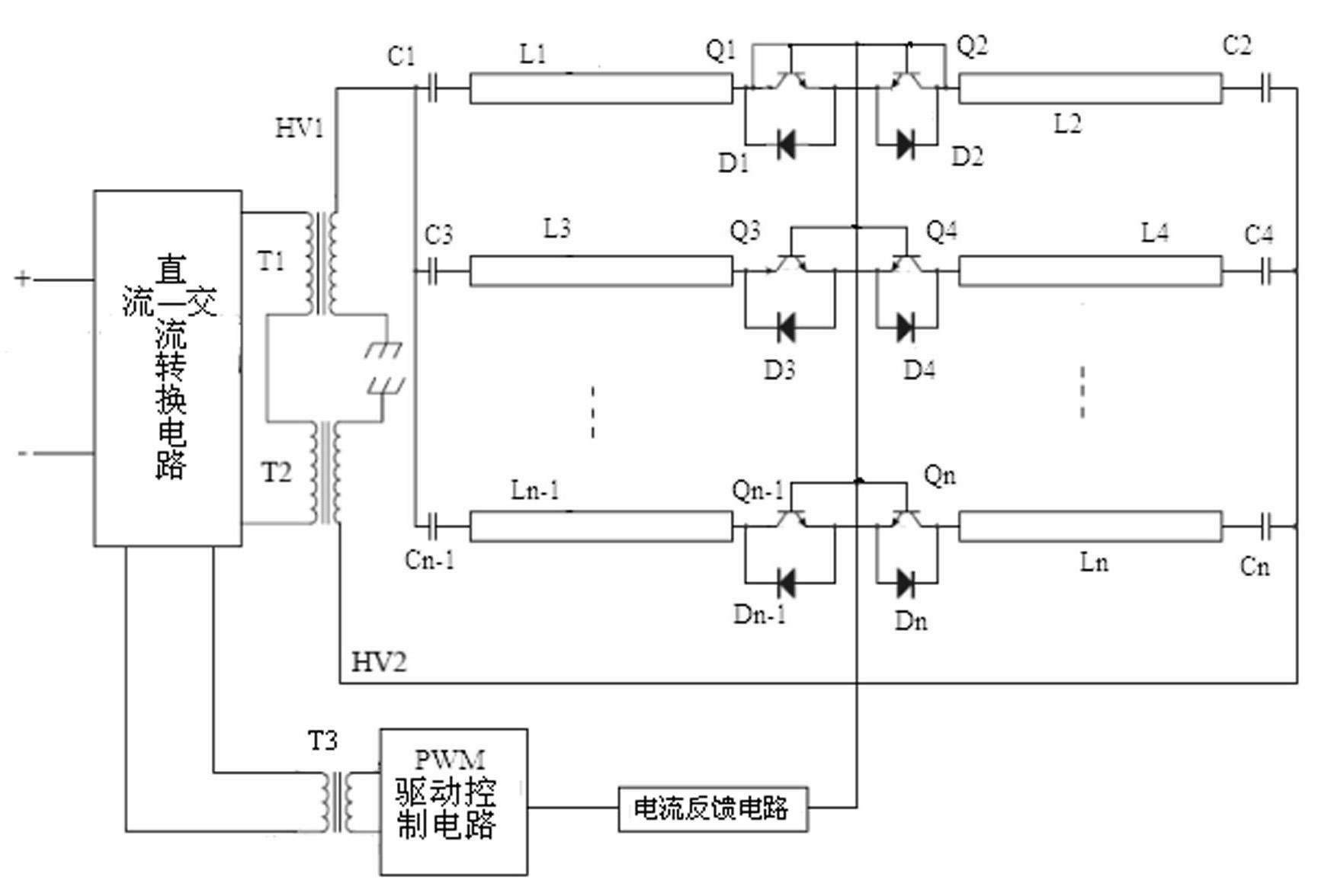

[0015] Such as figure 2 As shown, the driving circuit of the CCFL lamp tube of the present invention includes: a DC-AC conversion circuit that converts an input DC voltage into an AC voltage for driving multiple CCFL tubes; a high-voltage transformer T1 and a primary side connected to the DC-AC conversion circuit High-voltage transformer T2, the secondary side of high-voltage transformer T1 generates high-voltage HV1, and the secondary side of high-voltage transformer T2 generates high-voltage HV2; the primary side is connected to the PWM drive control circuit, and the secondary side is connected to the isolation drive transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com