Multi-channel adaptive load led constant current drive circuit

A self-adaptive load, constant current drive technology, applied in the direction of lamp circuit layout, electric light source, lighting devices, etc., can solve the problems of small size, low constant current precision, driving LED can not be changed at will, to achieve simple circuit structure, constant The effect of high flow accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

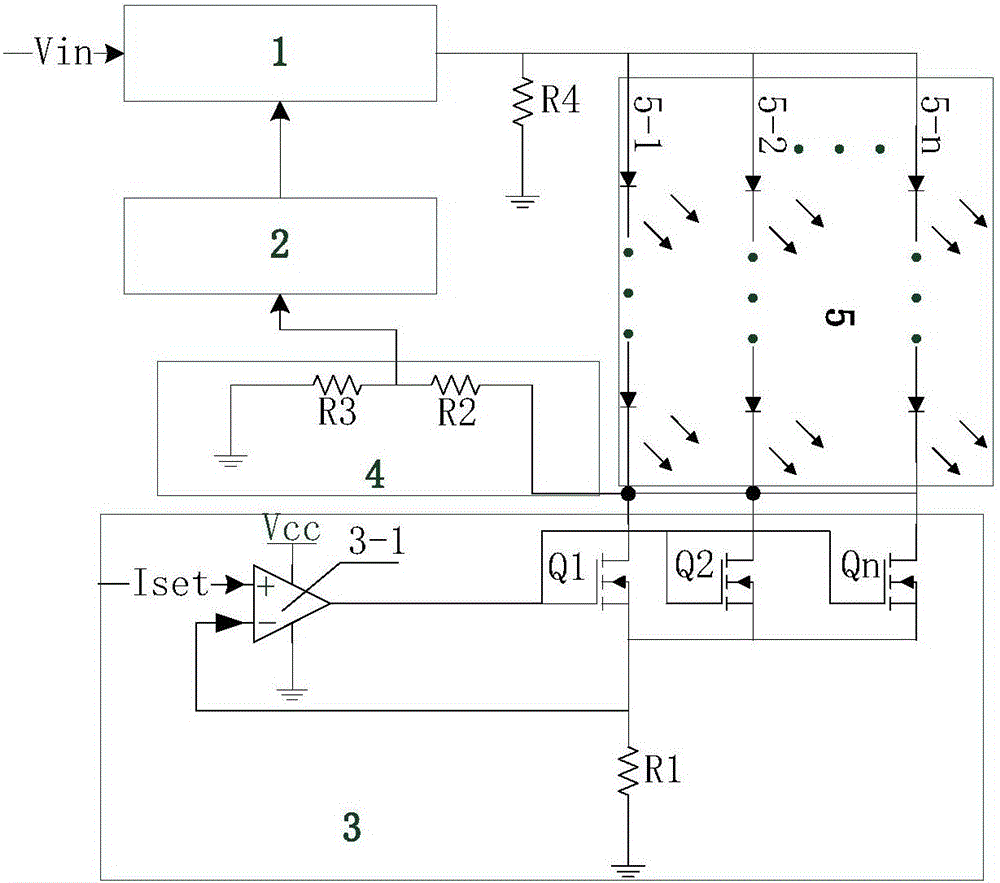

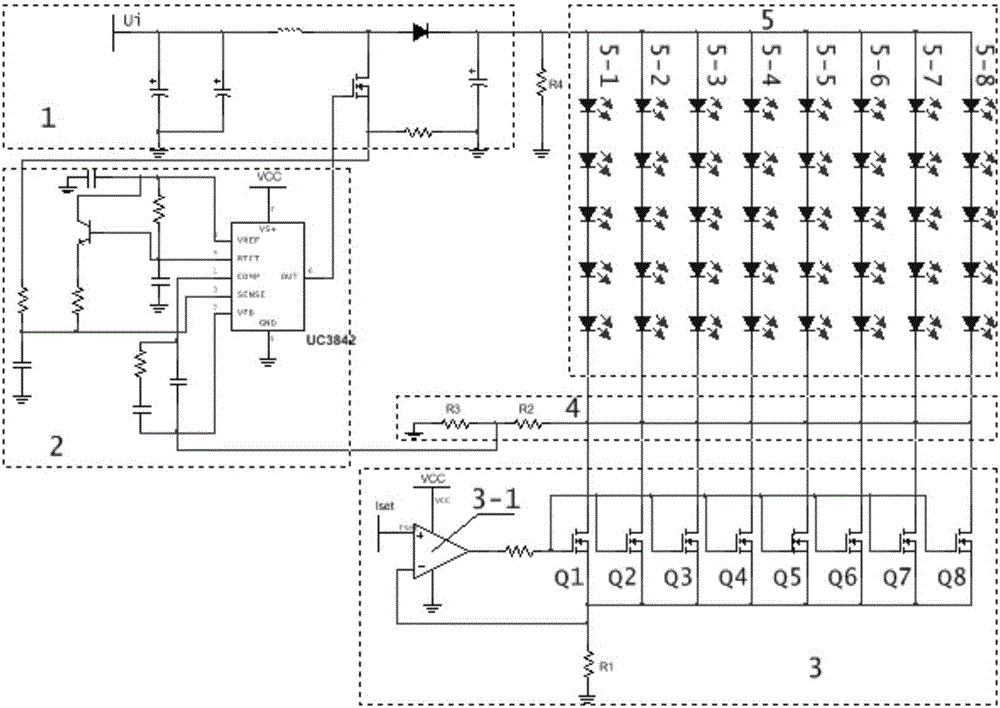

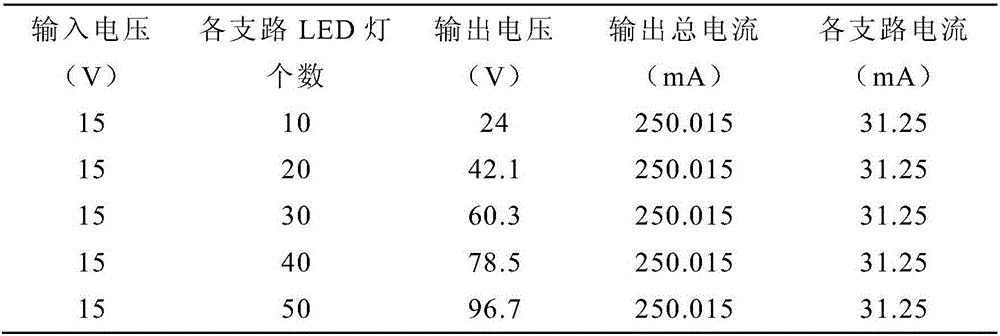

[0014] like figure 1 As shown, the multi-channel self-adaptive load LED constant current drive circuit provided by the present invention includes a boost circuit 1 , a control circuit 2 , a closed-loop constant current mirror drive circuit 3 and a sampling circuit 4 . The closed-loop constant-current mirror drive circuit 3 includes an operational amplifier 3-1, power MOS transistors Q1-Qn equal in number to the number of LED lamp string groups 5, and a current-limiting resistor R1. The sampling circuit 4 includes sampling resistors R2 and R3 connected in parallel. The output end of the boost circuit 1 is connected to the anode of each LED light string 5-1~5-n in the LED light string group 5, and the cathode of each LED light string 5-1~5-n is respectively connected to a corresponding power The drains of MOS transistors Q1~Qn are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com