Power mos tube and its manufacturing method

A technology of a MOS tube and a manufacturing method, which is applied in the field of power MOS tube and its manufacturing, can solve the problems of avalanche breakdown and small breakdown voltage of the power MOS tube, so as to improve the breakdown voltage, reduce the parasitic capacitance, and reduce the power line density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

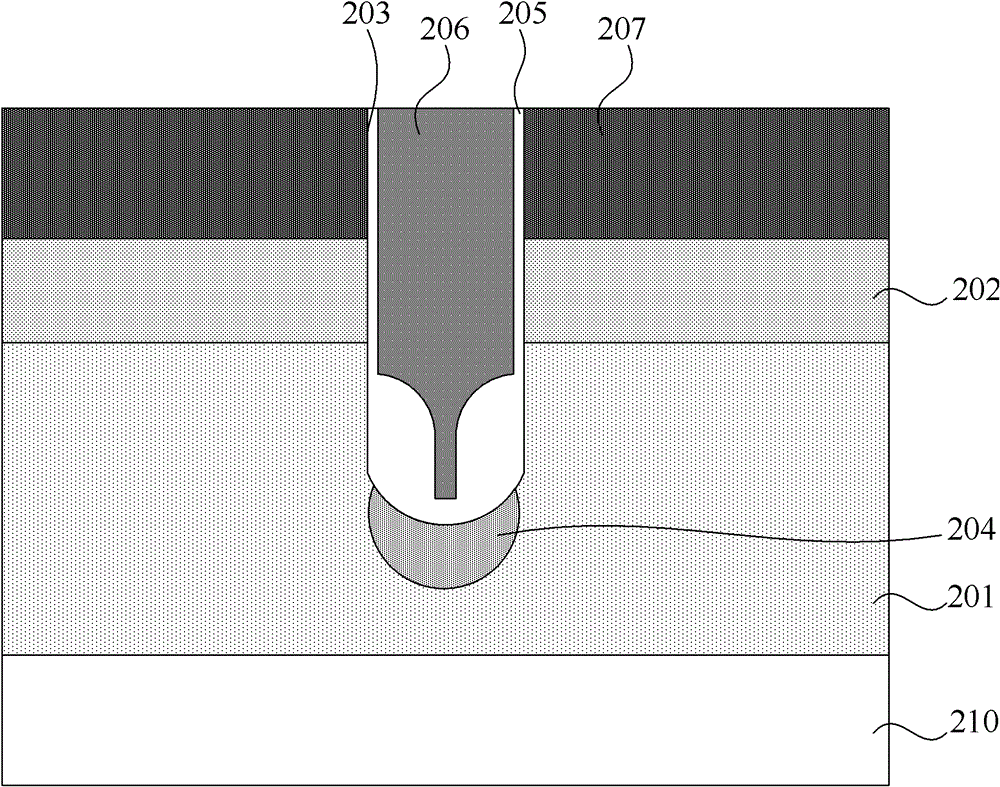

[0036] The following will combine image 3 ~ FIG. 5 further describes in detail the power MOS transistor and its manufacturing method of the present invention.

[0037] see image 3 The power MOS transistor of the present invention includes a drain region 201, a body region 202 formed on the drain region 201, a U-shaped gate trench 203 arranged in the body region 202 and the drain region 201, and arranged in the The side wall of the U-shaped gate trench 203 and the gate oxide layer 205 at the bottom end fill the gate 206 formed by the U-shaped gate trench 203, and are arranged in the drain region 201, close to the U-shaped gate. The floating ring 204 at the bottom of the pole trench 203, and the source region 207 arranged on both sides of the U-shaped gate trench 203 and below the surface of the body region 202, wherein the bottom of the U-shaped gate trench 203 The surface of the gate oxide layer 205 is approximately V-shaped, and the bottom end surface of the gate 206 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com