Rotor cooling type automobile permanent magnet liquid cooling retarder

A cooling and retarder technology, which is applied to electric vehicles, asynchronous inductive clutches/brakes, vehicle components, etc., can solve the problems of complex structure, poor working reliability and high manufacturing cost of the retarder, and achieves simple structure and high performance. High reliability and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

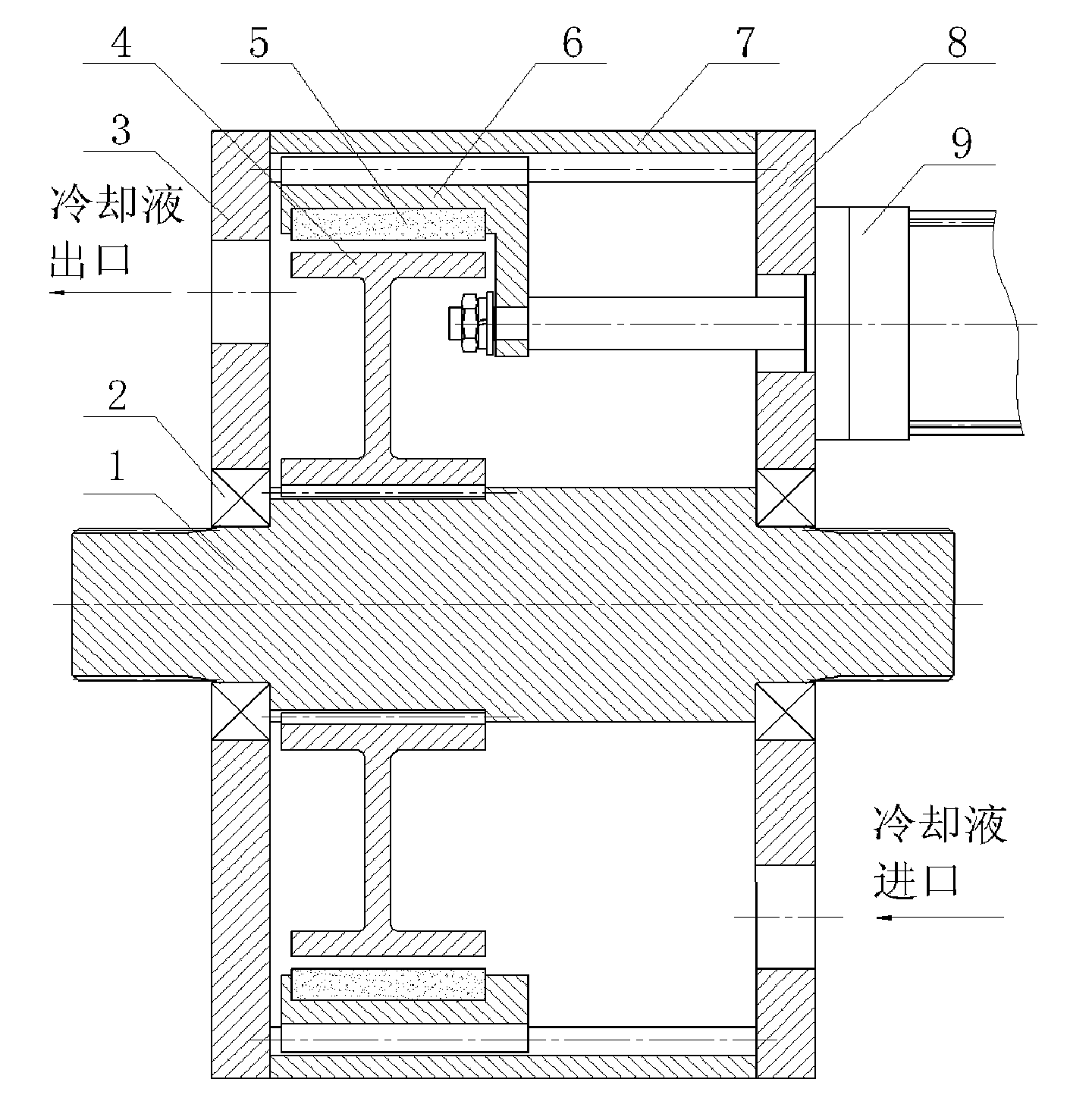

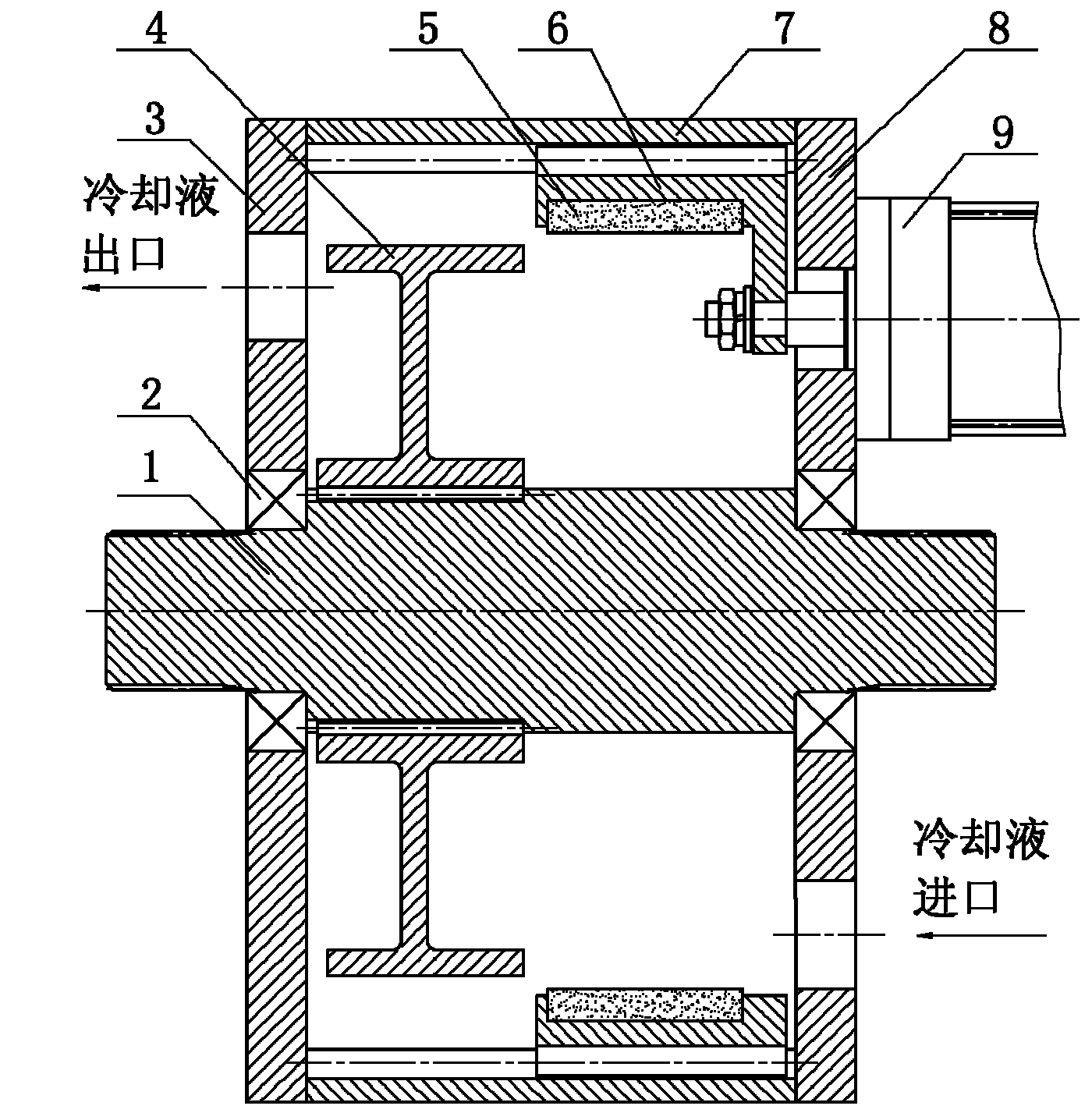

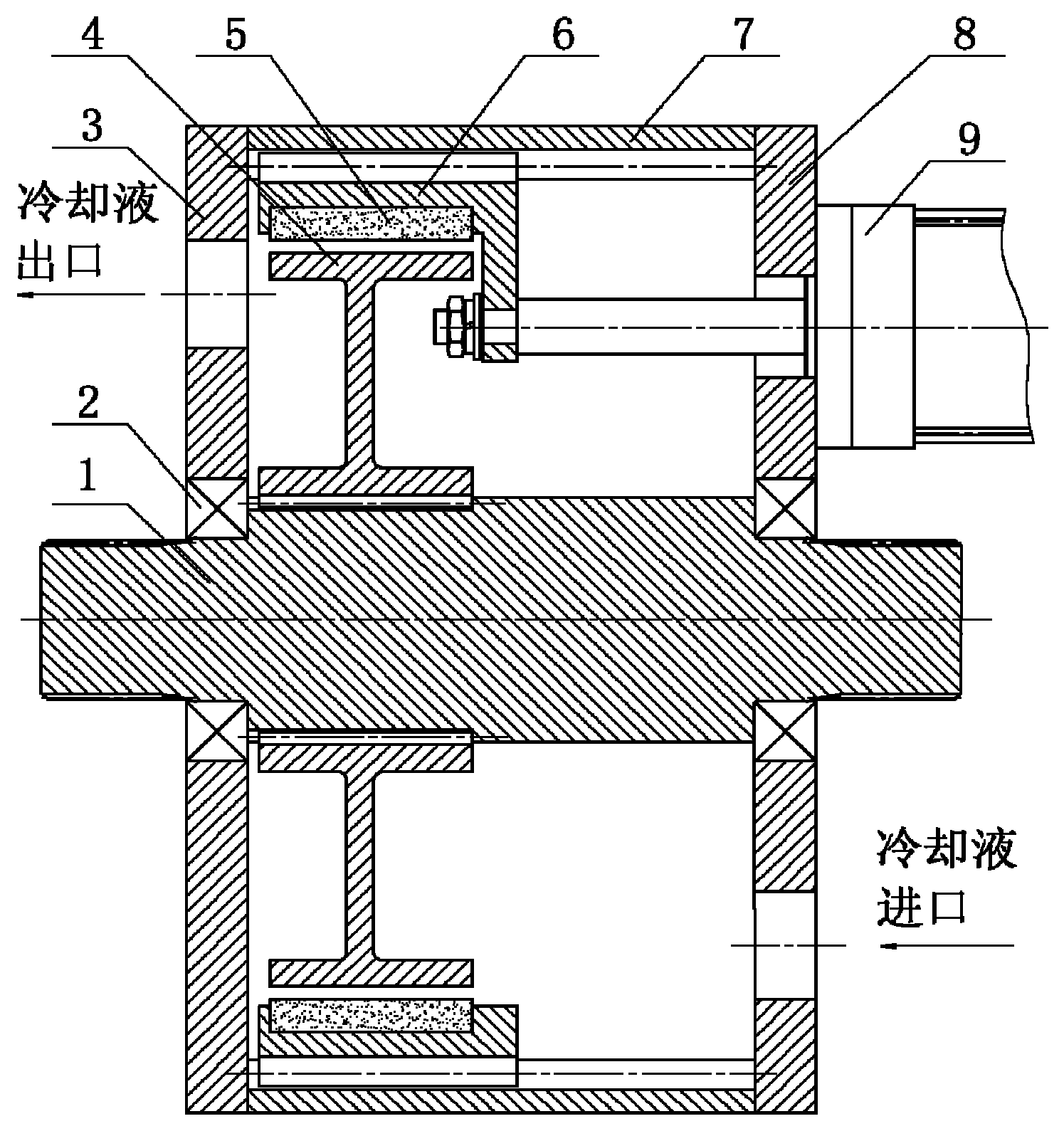

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] The specific structure of the present invention is as figure 1 , figure 2 As shown, it includes a stator, a rotor 4, a cylinder 9 and a transmission shaft 1. The drive shaft 1 is connected with the vehicle drive train.

[0014] The rotor-cooled permanent magnet liquid-cooled retarder for automobiles includes a stator, a rotor 4 connected to the drive shaft 1, and a cylinder 9; it is characterized in that the stator is composed of a left end cover 3, a stator hub 7, a permanent magnet 5, The cage 6 and the right end cover 8 are composed, the left end cover 3 and the right end cover 8 are fixed on both sides of the stator hub 7, the permanent magnet 5 is uniformly fixed on the magnet holder 6 in the circumferential direction, and the magnet holder 6 is placed inside the stator hub 7 One side of the magnet holder 6 is connected with the piston of the cylinder 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com