Plant culture container

A cultivation container and container technology, applied in the field of plant cultivation equipment, can solve the problems of incomplete pruning, uneven distribution of transplanted roots, non-reusable use, etc., and achieve the effect of increasing ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

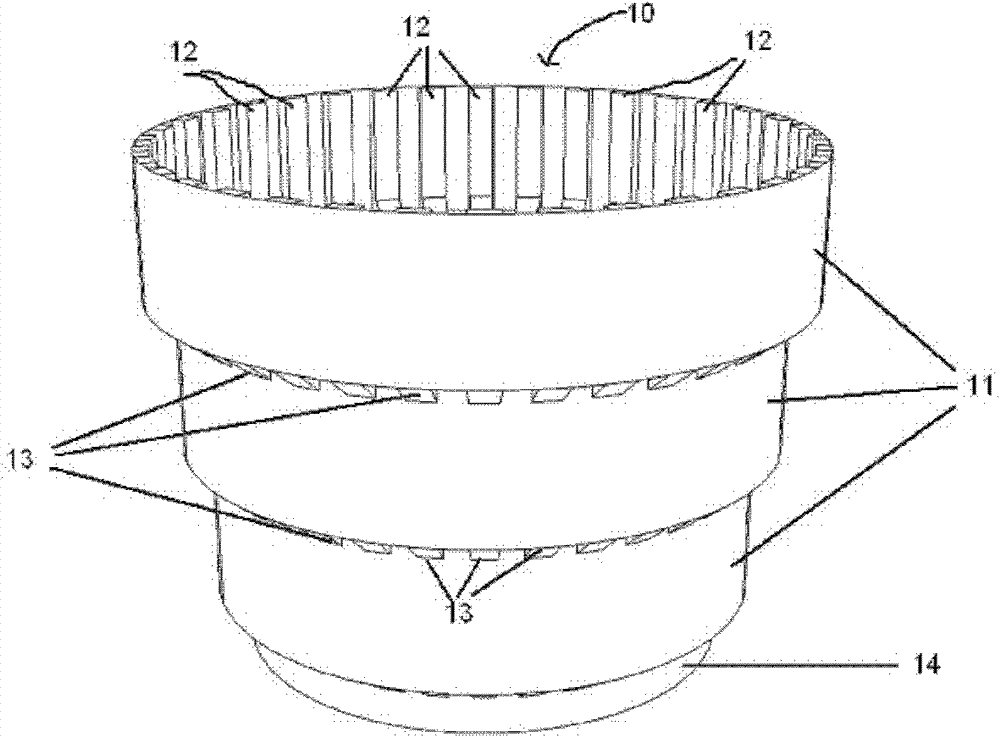

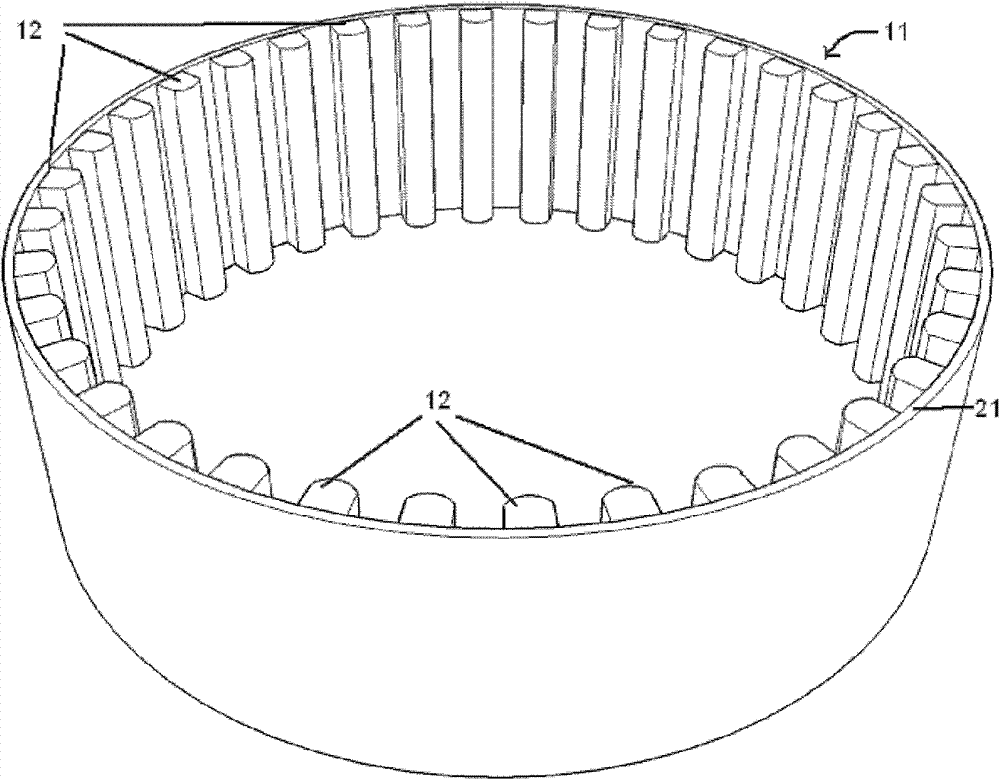

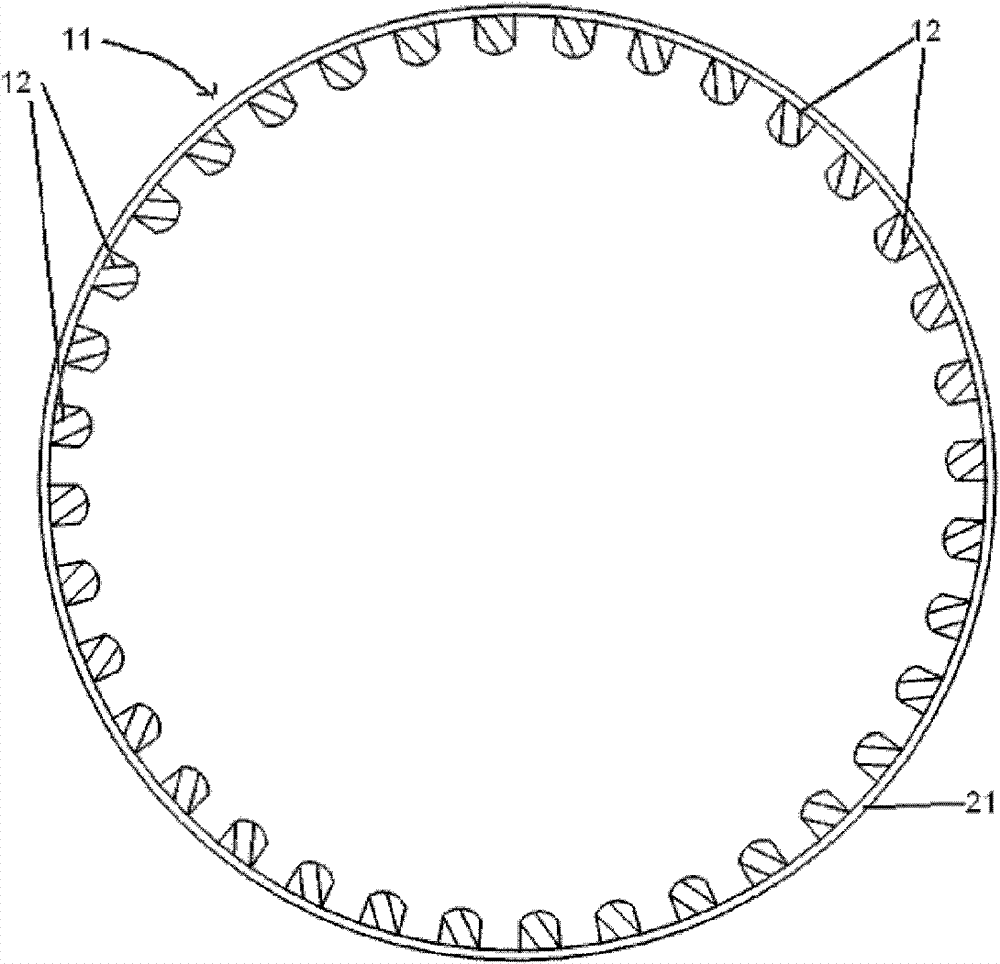

[0032] Embodiment 1 Its structure is as figure 1 As shown, the container 10 is placed horizontally, and its upper part is open, including side walls and a bottom. Its side wall is made up of 3 side wall segments 11 with ribs arranged vertically at intervals on the inner surface and a side wall segment 14 without ribs (all of the three side wall segments may also have ribs or only any one side wall segment may have ribs ). The side wall section 11 (see figure 2 , image 3 ) is a cylinder or a truncated cone with a large top and a small bottom, and its inner surface is densely covered with ribs 12 for guiding the root tip to grow downward. The side wall of the container 10 is composed of three concentric side wall segments 11 connected in series from top to bottom. For adjacent two side wall segments 11 , the lower opening cross section of the upper side wall segment is larger than the upper opening cross section of the lower side wall segment. Adjacent side wall sections ...

Embodiment 2

[0039] Example two as Figure 5 , Figure 6 shown. Figure 5 It is a partial sectional view of the container 60 of the present embodiment, Figure 6is a horizontal cross-sectional view of the side wall segment 11 on the side wall of the container 60 . The container 60 is specially designed for plants with thicker roots, such as orchids, cycads and the like. The basic structure of the side wall of the container 60 in this embodiment is the same as in the first embodiment, except that all the ribs in the first embodiment have the same size, and in this embodiment, every two common ribs 12 are accompanied by a thickened rib 61 (see Figure 6 ), also can be a rib in every two ribs to be thickening rib, the thickness of thickening rib 61 wants thick 3~8 millimeter than common rib 12. At the joints of adjacent side wall sections 11, the connecting ribs 13 are only connected to the thicker ribs 61, or the thickened ribs 61 are directly extended as the connecting ribs. The botto...

Embodiment 3

[0040] Embodiment Three The horizontal section of the side wall section 11 of the container 80 in this embodiment is as follows: Figure 7 shown. The basic structure of the side wall of the container 80 in this embodiment is also the same as that of Embodiment 1, the difference is that: when the ribs are arranged on the side wall section 11 in this embodiment, a common rib 12 with an equal number of intervals is distributed to prevent rooting Coiled intercepting ribs 81 . The thickness of the intercepting ribs 81 is 1-5 mm thicker than the common ribs 12, and the specific thickness is determined by the root diameter of the cultivated plants. The intercepting ribs 81 can be symmetrically distributed in 2, 4 or 8 evenly on the inner surface of the side wall section 11 . The bottom of the container 80 is a screen-like plane filled with through-holes, the spacing between the through-holes of the screen being preferably less than 3 mm. The inner surface of the bottom has an upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com