Processing technology for exhaust pipe sealing ring

A processing technology and sealing ring technology, which is applied to the processing technology field of multi-turn stacked exhaust pipe sealing ring, can solve the problem that the sealing ring is not suitable for closed sealing ring, etc., and achieves the effect of ensuring the flatness and improving the spring pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

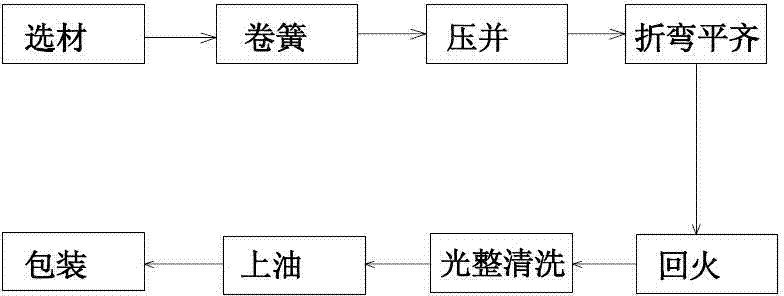

[0028] Example: A processing technology of the exhaust pipe sealing ring (see attached figure 1 ), including the following steps:

[0029] (1) Select the material, select a single layer of strip material, and coil the spring on the multi-roll winding unit to form a two-loop structure, cut off the ends of the strip material to form a thick seal ring, and the distance between the two ends is 4 times the width of the strip material, the multi-roll winding unit adopts 5 round rollers arranged symmetrically in the center, the round rollers are enclosed in a circle, and the pitch rollers are arranged at the positions corresponding to the round rollers, and the pitch rollers are arranged in a wave shape , The strip material is rolled into a wave shape when passing through the position of the pitch roller;

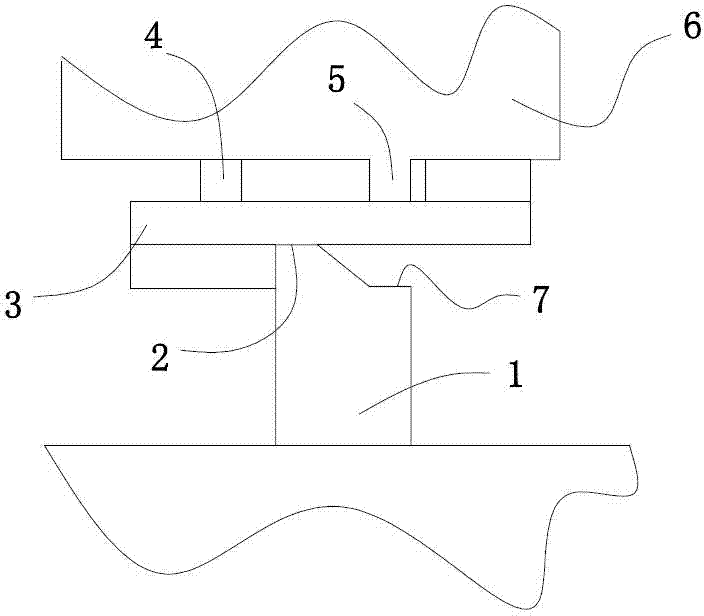

[0030] (2) Combine the rough embryo and place the coil spring on the compression mold. The compression mold has a wave-shaped undulating surface, which corresponds to the wave shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com