Bearing convexity ultra-precision grinding head

A bearing and precision head technology, which is applied in the field of fine grinding equipment for large-scale bearing rings, can solve the problems that cannot improve the roundness, waviness, and straightness of the working surface of the bearing, and achieve the goal of improving work efficiency, quality, and roundness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

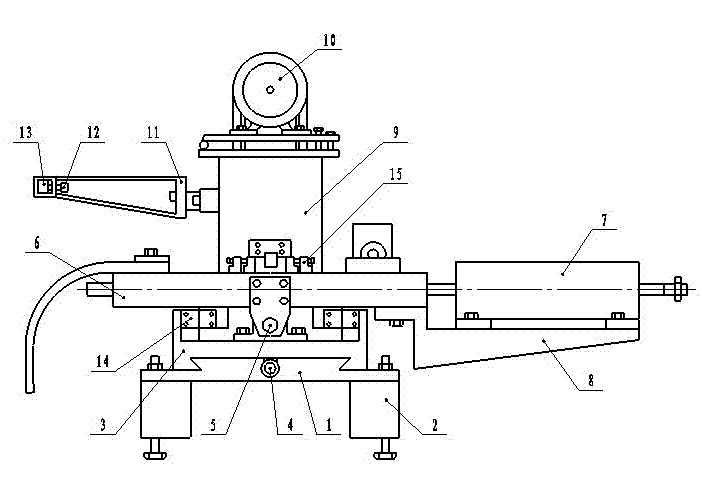

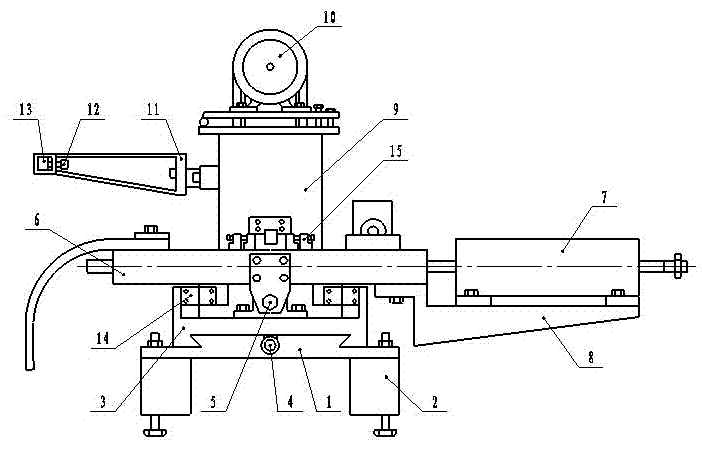

[0012] Such as figure 1 As shown, the bearing convexity super precision head of the present invention includes: lower seat plate 1, cushion block 2, mounting plate 3, horizontal adjustment screw 4, horizontal feeding oil cylinder 5, sliding platform 6, longitudinal feeding oil cylinder 7, support Board 8, oscillation generating box 9, oscillation motor 10, oscillation head 11, top screw 12, oil stone 13, first cross guide rail 14 and second cross guide rail 15, lower seat plate 1 is located above pad 2, lower seat plate 1 and block 2 are fixed on the machine tool by bolts, the mounting plate 3 is installed on the dovetail guide rail of the lower seat plate 1, the horizontal adjustment screw 4 is fixed on the lower seat plate 1, and the transmission seat on the horizontal adjustment screw 4 is fixed on the installation The lower end of plate 3.

[0013] A pair of first cross guide rails 14 are respectively installed on both sides of the mounting plate 3, and the transverse fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com