Conduction band cleaning-prebaking device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

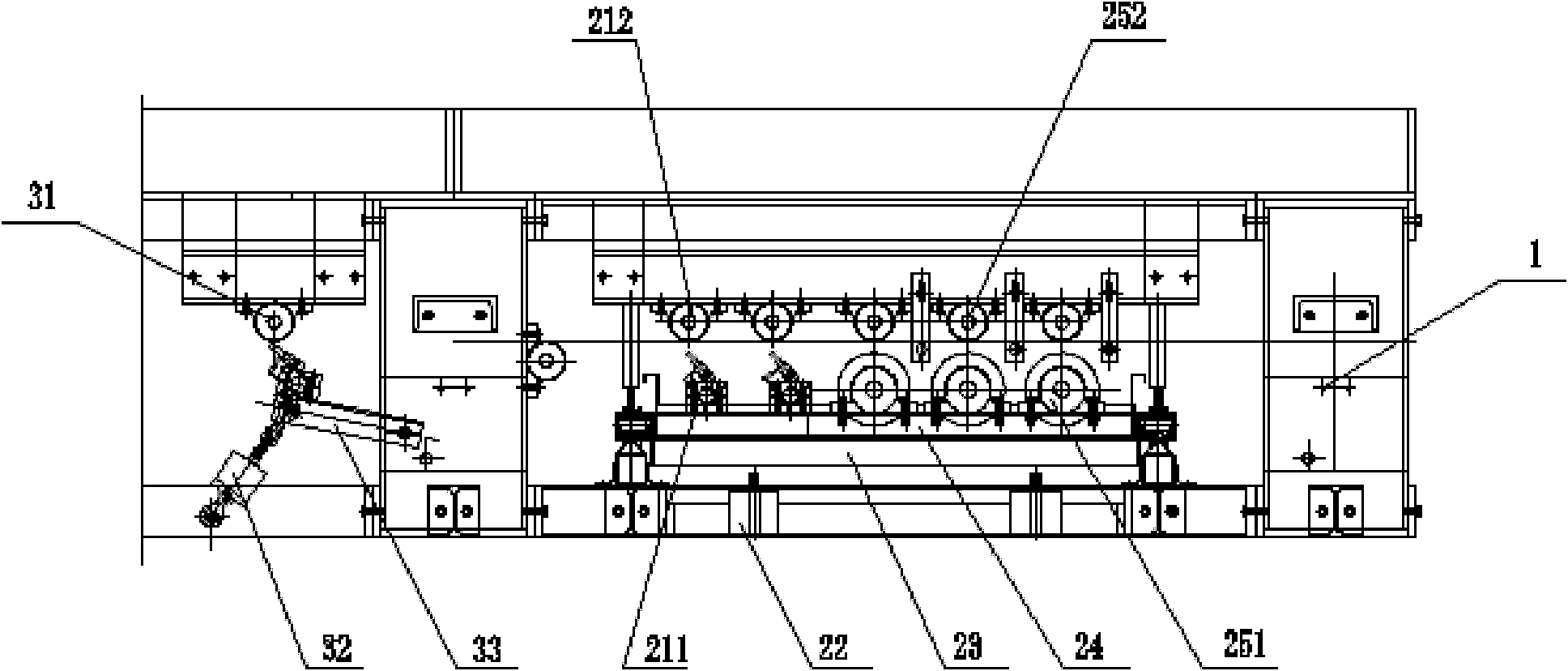

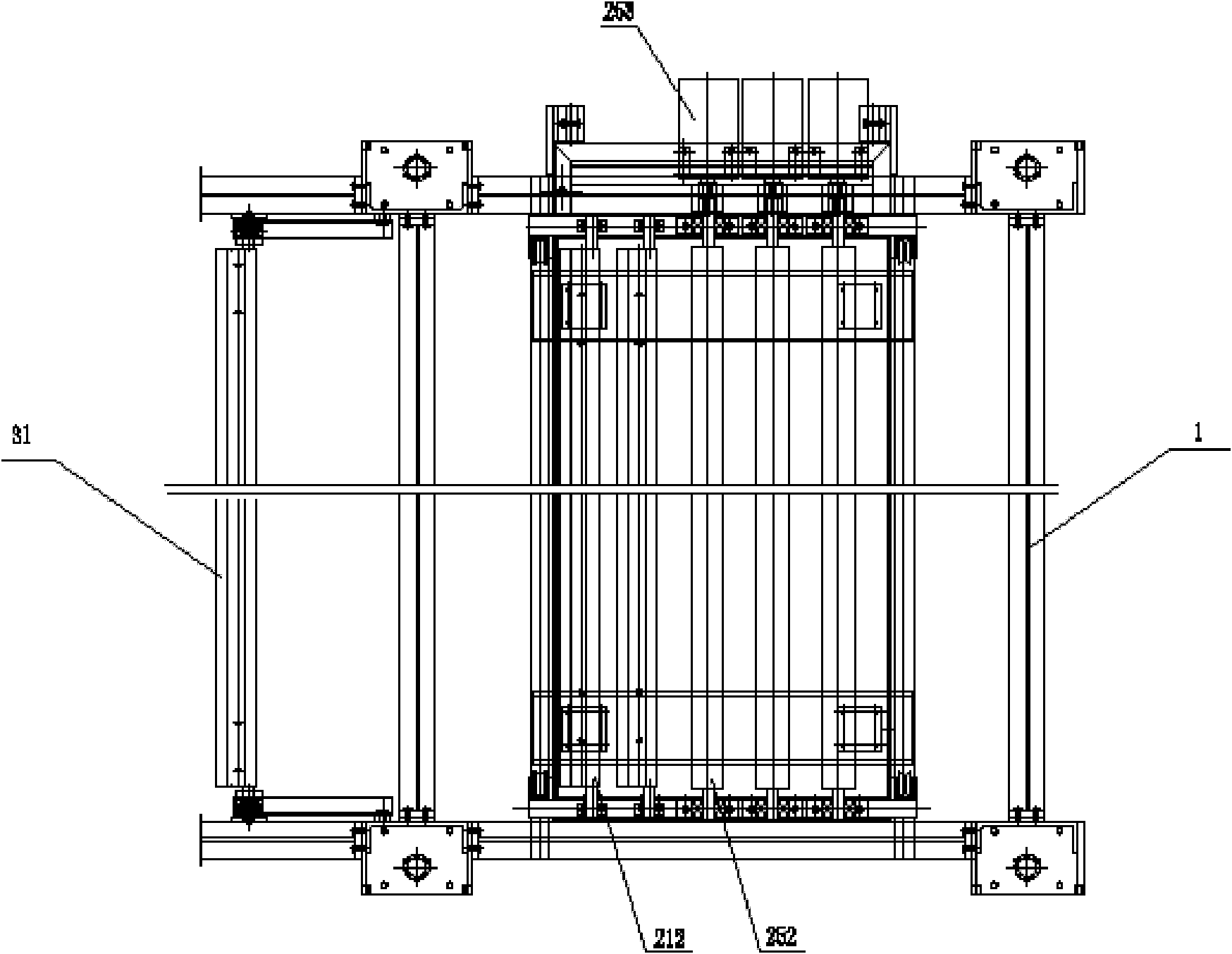

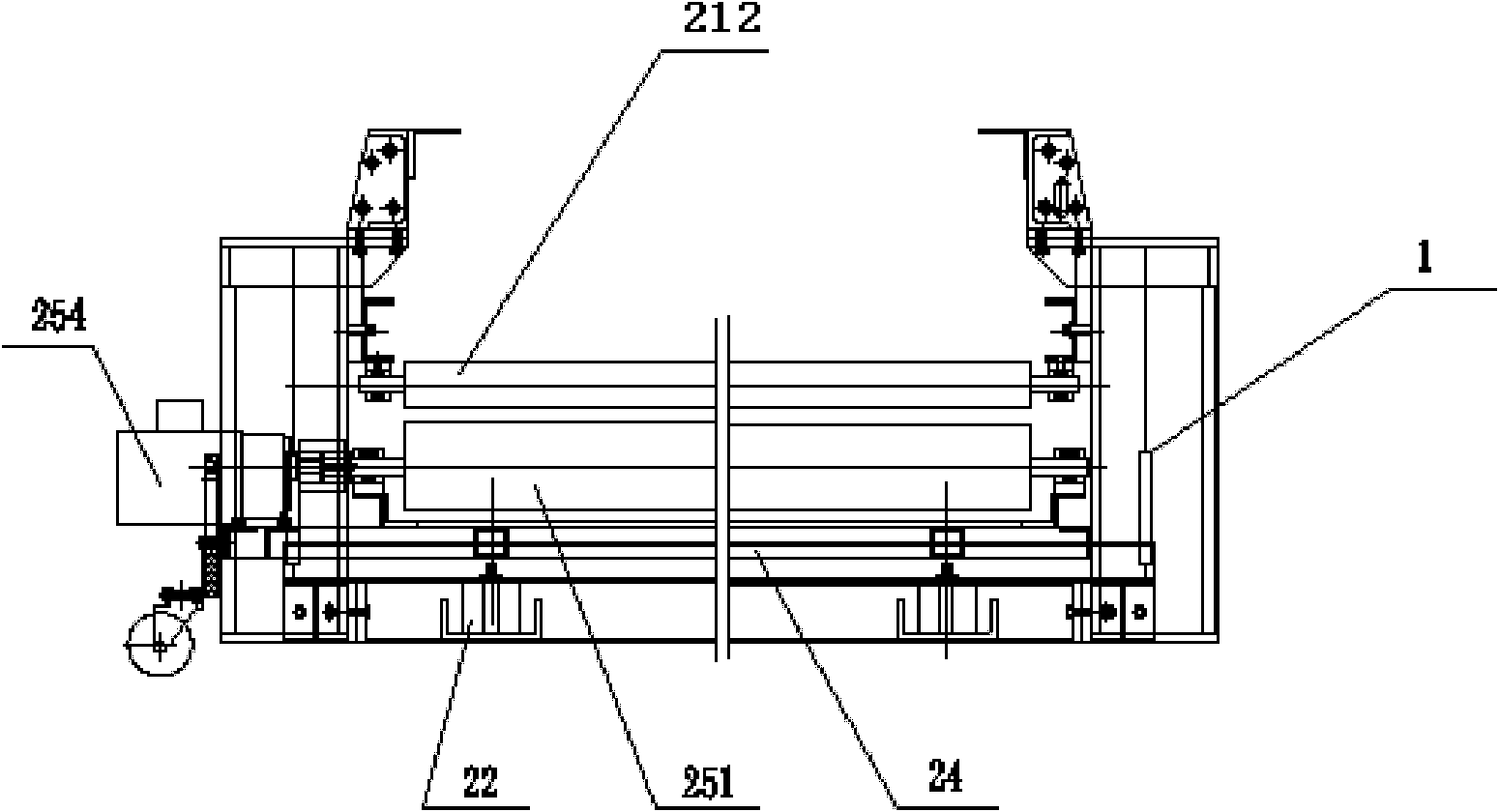

[0016] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as Figures 1 to 3 As shown, the guide belt cleaning-pre-drying device of the present invention includes a machine base 1 and a guide belt conveying device, a water washing device and a pre-drying device respectively installed on the machine base 1, and the guide belt conveying device includes a driving motor 253, the main drive roller 252 and the idler roller 212, the drive motor 253 adopts a geared motor; the output shaft of the drive motor 253 is connected with the main drive roller 252, and the guide belt is coated on the periphery of the main drive roller 252 and the idler roller 212; The water washing device includes a front-stage spraying pre-washing device, a middle-stage scrapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com