Multi-layer three-dimensional texture substrate and manufacturing method thereof

A manufacturing method and substrate technology, which can be used in coatings, decorative arts, special decorative structures, etc., can solve the problems of monotonous appearance and insufficient variability of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

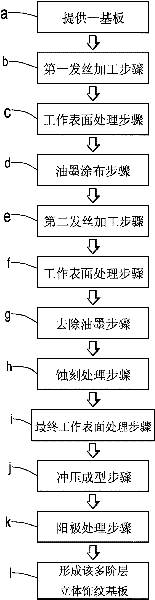

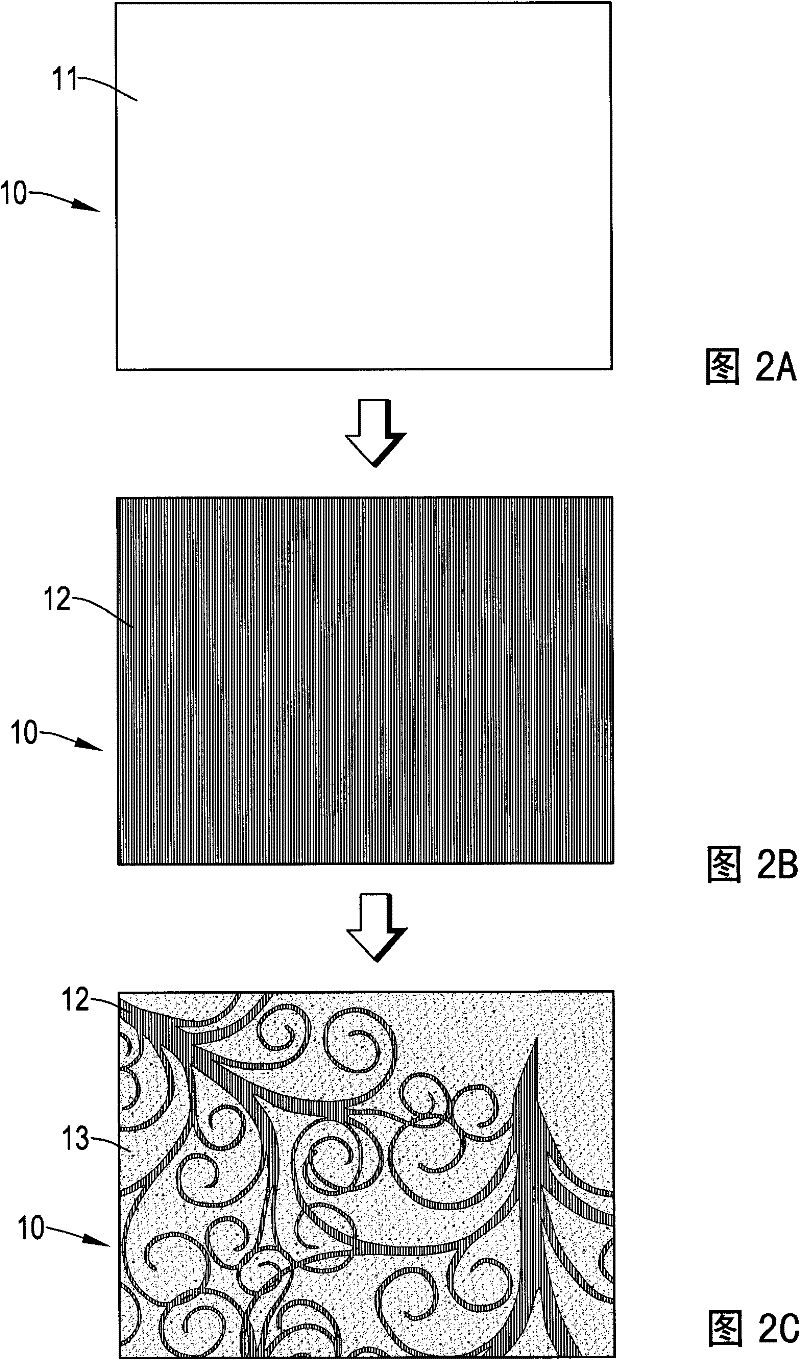

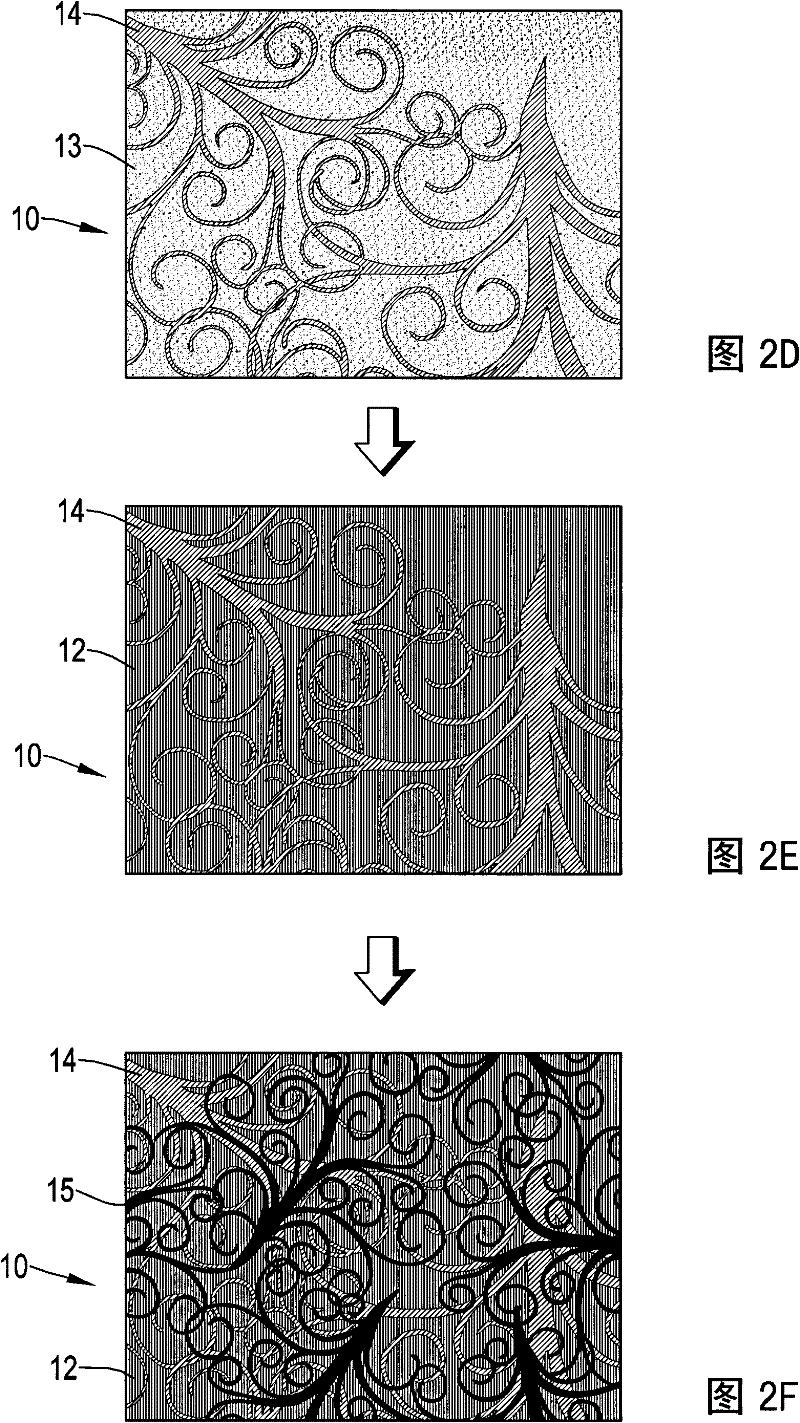

[0045] Please see figure 1 As shown in FIG. 2, the method for manufacturing the multi-layer three-dimensional decorative substrate of the present invention includes:

[0046] A substrate a is provided. In this embodiment, an aluminum alloy plate is used as the substrate 10. The substrate 10 has a working surface 11, such as Figure 2A shown;

[0047] The first hairline processing step b, which is to use a thinner abrasive cloth belt to perform first hairline processing on the working surface 11 of the substrate 10, so as to form a plurality of first hairline lines 12 on the working surface 11 of the substrate 10, Such as Figure 2B shown;

[0048] The working surface treatment step c includes cleaning and degreasing the working surface 11 of the substrate 10, and performing chemical treatment to form a bright surface or a matte surface as required, and then baking to remove water stains on the working surface 11 of the substrate 10;

[0049] The ink coating step d includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com